Installation data – Airedale Air Cooled Condensers R410A User Manual

Page 13

Condensers

CR12

– CR105

Condensers

13

Installation & Maintenance : 6680953 V1.2.0 02/2013

Installation Data

PIPEWORK INSTALLATION - GOOD PRACTICES

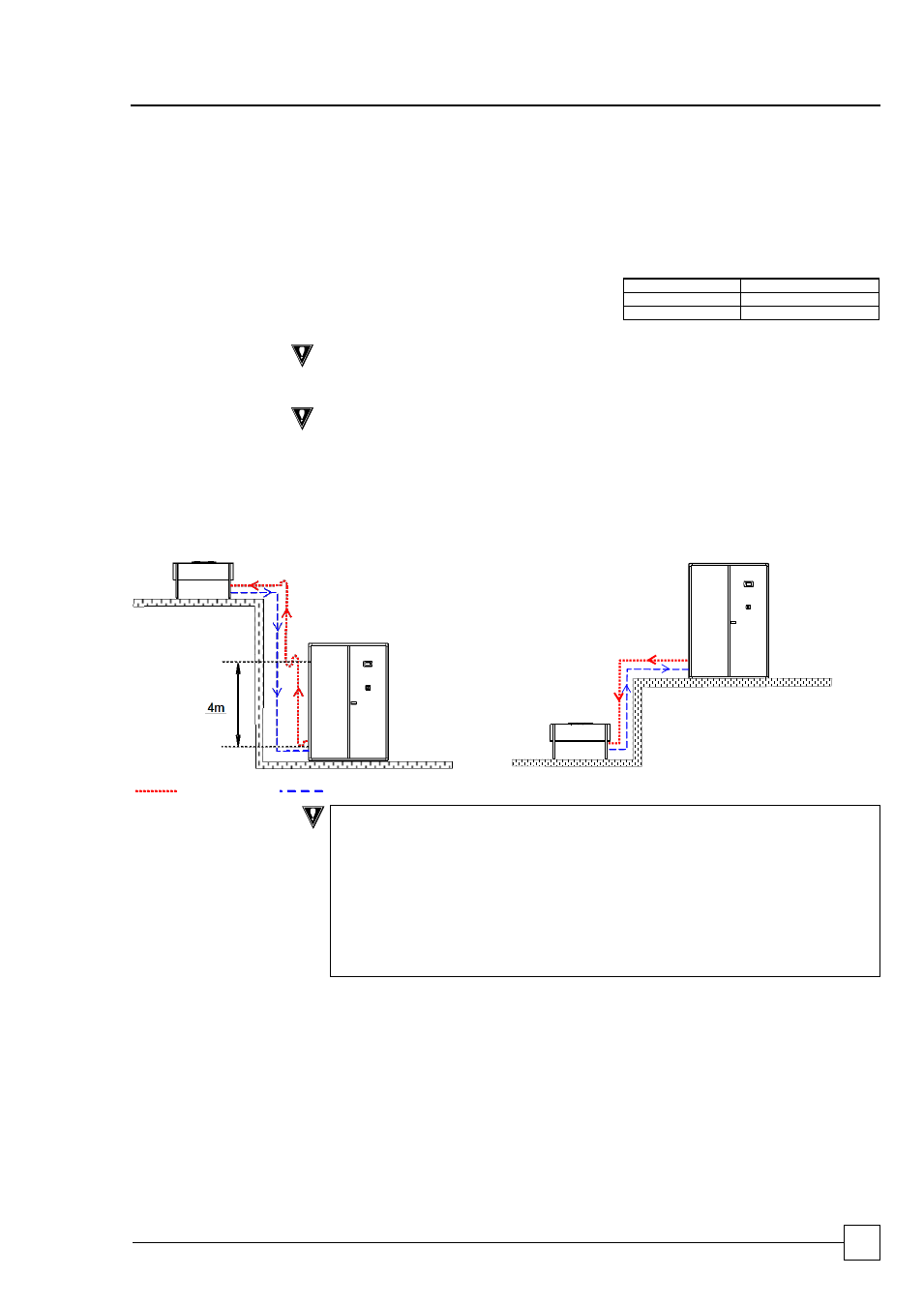

Oil Traps

For long vertical rises in discharge lines, it is essential that oil traps are located every 4m

to ensure proper oil movement / entrapment. In addition there should be an oil trap at the

exit of the air handling unit before a vertical riser is applied (refer to example below).

Pipe Supports

The following table identifies the maximum

distance between pipe supports on vertical

and horizontal pipe runs.

Pipe O/D (inches)

Support distance (m)

3/8 - 7/8

1.0

1 1/8 - 2 1/8

2.0

CAUTION

All pipework should be clamped prior to insulation being applied.

Pipe lengths

CAUTION

DISCHARGE LINE:

Maximum pressure loss for discharge pipework 42 kPa.

Minimum velocity for discharge risers 5 m/s, to ensure good oil return.

LIQUID LINE:

Maximum pressure loss for liquid line pipework 21 kPa.

Minimum velocity for liquid line 1.5 m/s, to ensure good oil return.

Condenser above Air Handling Unit

Condenser below Air Handling Unit

t

Discharge Line

Liquid

IMPORTANT

It is the responsibility of the installing contractor/site engineer to check the pipe

size/refrigerant charge is correct for each system installation and application.

Split systems may require additional oil which should be added to the low

pressure side of each compressor.

Design should be in accordance with accepted refrigeration practice to ensure

good oil return to the compressor(s) under all normal operating conditions.

REMEMBER excessive pressure loss in interconnecting pipework will impair

system performance; this should be factored in during the design of the system

and where necessary oil traps employed.