4wir, S.lin, Corr – West Control Solutions TB 45 Temperature Monitor User Manual

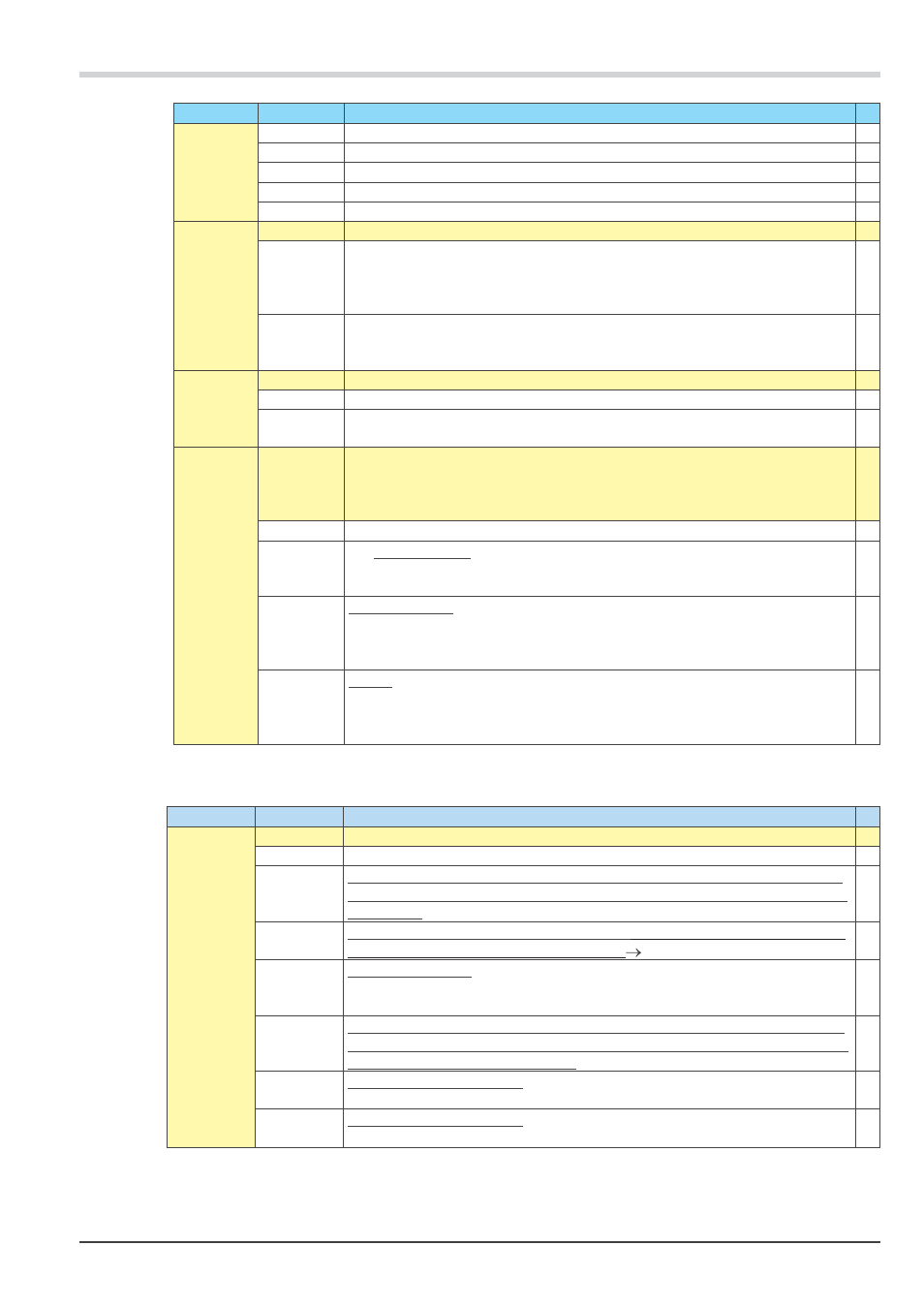

Page 35: Fnc.1

Name

Value range Description

47

Special (-200..200 mV)

50

Potentiometer 0...160 Ohm

51

Potentiometer 0...450 Ohm

52

Potentiometer 0...1600 Ohm

53

Potentiometer 0...4500 Ohm

4wir

Resistance connection type (Inp.1 only)

0

3-wire connection

Normally, resistance and resistance thermometer measurements are in three-wire

technology, based on the assumption that the lead resistance in all supply leads is

equal.

1

4-wire connection

with measurement in four-wire connection, the lead resistance is measured via refe-

rence leads.

S.Lin

Linearization only adjustable with

S.tYP:18, 23 ... 47

0

none

1

Special linearization. Producing a linearization table is possible via BlueControl (Engi-

neering-Tool). Preset is the characteristic for KTY 11-6 temperature sensors.

Corr

Measured value correction / scaling:

When using current, voltage orr (version-dependent) resistance signals as input va-

riables, scaling at parameter level is possible. Specify the input value of the lower

and upper scaling point in units of the relevant electrical quantity (mA / V/ Ohm).

0

No correction

1

The offset correction (at CAL level) is possible on-line at the process. If InL shows the

lower input value of the scaling point, OuL must be set to the relevant display value.

Adjustment is via the instrument front panel.

2

2-point correction (at CAL level) is possible off-line by means of a process value

transmitter. Specify the process value for the lower and the upper scaling point and

confirm it as input value InL or InH. Now, adjust the relevant display value OuL or

OuH. Adjustment is via instrument front panel operation.

3

Scaling (at PArA level) for current and voltage signals as input variables also for re-

sistance signals dependent on version). The input and display value values for lower

(InL, OuL) and upper scaling point (InH, OuH) are visible at parameter setting level.

Adjustment is via instrument front panel operation, or via the engineering tool.

Limit values LC, Lim2, Lim3

Name

Value range Description

Fnc.1

Function of main alarm LC

0

switched off

1

Measured value monitoring. When exceeding the limit value, an alarm is output and

reset automatically, when the measured value is "within the limits" (including hyste-

resis) again.

2

Measured value monitoring + alarm status latch

. A stored limit value can be reset by

pressing the RESET key or via the digital input (

LOGI/ Err.r).

3

Temperature monitor fo

r high limit value + latch: measured value monitoring + high

limit value alarm status latch. A stored limit value can be reset via a digital input or

by pressing the RESET key (-> LOGI/Err.r).

4

Temperature monitor for low limit value + latch: measured value monitoring + low li-

mit value alarm status latch. A stored limit value can be reset via a digital input or by

pressing the RESET key (-> LOGI/Err.r).

5

Temperature monitor function for exceeded high limit value. The limit value is not

stored.

6

Temperature monitor function for exceeded low limit value. The limit value is not sto-

red.

Configuration level

TB 45

Configuration

35