Body style versus application, Way valves – Warren Controls 5800 Series Compact Globe Control Valves User Manual

Page 6

6

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

5800_IOM_RevB_0413

BODY STYLE VErSUS APPLICATION

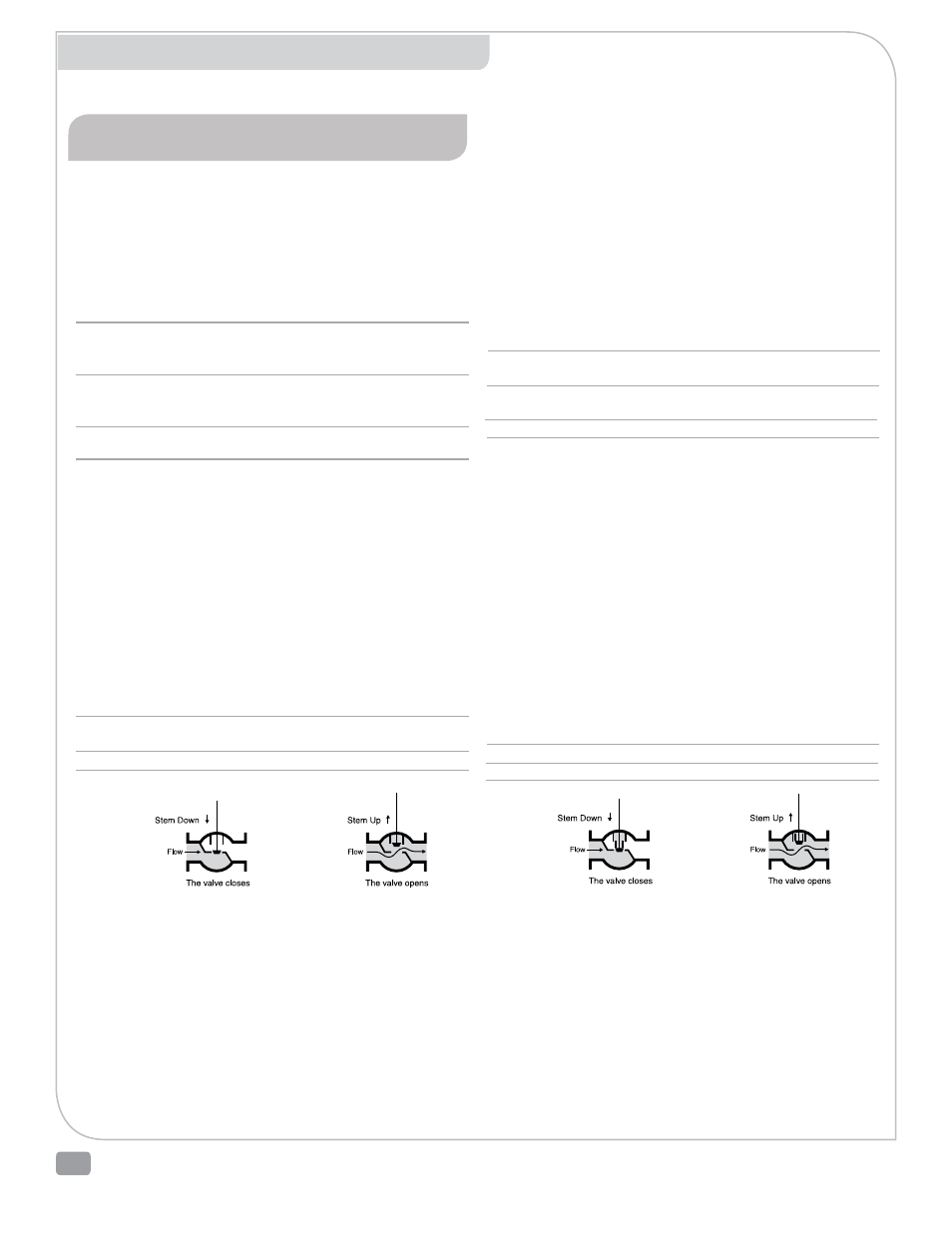

5840

2-Way Single Seat Unbalanced Valve

with Cage Retained Seat

The 5840 Valve is particularly effective for the control of liquids, gases,

and steam. It is a suitable solution for applications with dirty fluids and

high pressure drops. ANSI Class IV and VI shut-off.

Sizes:

1/2, 3/4, 1, 1-1/2, 2, 2-1/2, 3, 4 inch

Body:

WCB Steel or CF8M Stainless Steel

300 NPT or 300 Socketweld (1/2 thru 2),

150LB Flange or 300LB Flange (1/2 thru 4)

Trim:

EQ% or Linear, 316 Stainless Steel, TFE, PEEK, or Alloy

6 Wrapped 316 SS, 400 Stainless Steel,

Alloy 6 Wrapped 400 SS

Shut-off:

ANSI Class IV (Stainless Steel and Alloy 6 Trim),

ANSI Class VI (TFE and PEEK Trim)

Packing &

TFE V-Ring, Spring Loaded, w/ PEEK Bearings (+32

Bonnet:

to 450°F), TFE V-Ring, Spring Loaded, w/ Z PEEK

Bearings (+32 to 450°F), Adjustable Graphite

w/ PEEK Bearings (+32 to 450°F), Adjustable

Graphite w/ Z PEEK Bearings (+32 to 450°F),

Adjustable Graphite w/ Graphite Gaskets & Alloy

6 Bearings (+32 to 550°F), Adjustable Graphite

w/Graphite Gaskets, Graphalloy Bearings &

Extension Bonnet (+32 to 750F for NON-Oxidizing

Media ONLY) Adjustable Graphite w/ Graphite

Gaskets, Alloy 6 Bearings & Extension Bonnet (+32 to

800°F), Suitable for Oxidizing Media

Note: PEEK Bearings are best suited for chemical

applications. Z-PEEK Bearings are best suited for

water and steam applications.

Temperature: +32 to 450°F (TFE or PEEK Trim)

+32 to 800°F (Stainless Steel or Alloy 6 Trim)

Rangeability: 50:1

5843

2-Way Single Seat Caged Balanced Valve

with Cage Retained Seat

The 5843 is a balanced valve that is an effective solution for the control

of liquids, gases, and steam at higher pressures. It requires less force

to operate than unbalanced valves so smaller actuators can be used.

Its single seat o-ring seal design facilitates ANSI Class IV shut-off. It is

limited to cleaner fluids.

Sizes:

2-1/2, 3, 4 inch

Body:

WCB Steel, CF8M Stainless Steel

150LB Flange or 300LB Flange

Trim:

EQ% or Linear, 316 Stainless Steel, 400 Stainless Steel,

Alloy 6 Wrapped 400 SS

Shut-off:

ANSI Class IV (Fluoraz Seal) ANSI Class III (Metal Seal)

Packing &

TFE V-Ring, Spring Loaded, w/ PEEK Bearings and

Seal Bonnet: Fluoraz (+32 to 450°F), TFE V-Ring, Spring Loaded,

w/ Z PEEK Bearings and Fluoraz Seal (+32 to 450°F),

Adjustable Graphite w/ PEEK Bearings and Fluoraz

Seal (+32 to 450°F),

Adjustable Graphite w/ Z PEEK Bearings and Fluoraz

Seal (+32 to 450°F), Adjustable Graphite w/ Graphite

Gaskets & Alloy 6 Bearings and Fluoraz Seal (+32 to

450°F), Adjustable Graphite w/ Graphite Gaskets,

Graphalloy Bearings Metal Seal & Extension Bonnet

(+32 to 750F for NON-Oxidizing Media ONLY)

Adjustable Graphite w/ Graphite Gaskets, Alloy 6

Bearings Metal Seal, & Extension Bonnet (+32 to

800°F)

Note: PEEK Bearings are best suited for chemical

applications.

Z-PEEK Bearings are best suited for water and steam

applications.

Temperature: +32 to 800°F (Stainless Steel or Alloy 6 Trim)

Rangeability: 50:1

2-WAY VALVES

(Control of Liquids, gases, and Steam)