Operation true rpm – SHIMPO DT-721 User Manual

Page 2

Operation

True RPM

Internal Triggering

1. Firmly plug power cord into a 100VAC (Japan), 120 VAC

(US) or 230 VAC (Europe) single phase.

2. Aim light beam at object under observation. The best

distance between the strobe and moving object is

approximately 2 ft.

3. Measure rpm by turning setter. Turn setter to adjust the

flashing rate to the rotational speed of the object. To

reach the desired rate faster, use the 1/2 or x2 switches.

External Triggering

1. Connect wires according to connector pin designation:

Tip: signal

Sleeve: Gnd

2. Plug power cord into a 100VAC (Japan), 120 VAC (US)

or 230 VAC (Europe). Pull power trigger switch and

lock it. When the ext. phone jack is inserted in unit, the

strobe automatically switches from the internal mode to

the external.

3. The strobe will flash every time the sensor puts out a

pulse. See specifications table for input signal require-

ments.

4. If the input signal frequency exceeds upper or lower

limits, the alarm mark will be displayed and the strobe

will stop flashing.

Synchronous Output Signal

The Synchronous output signal appears on the tip of the

output phonejack.

See table for more information.

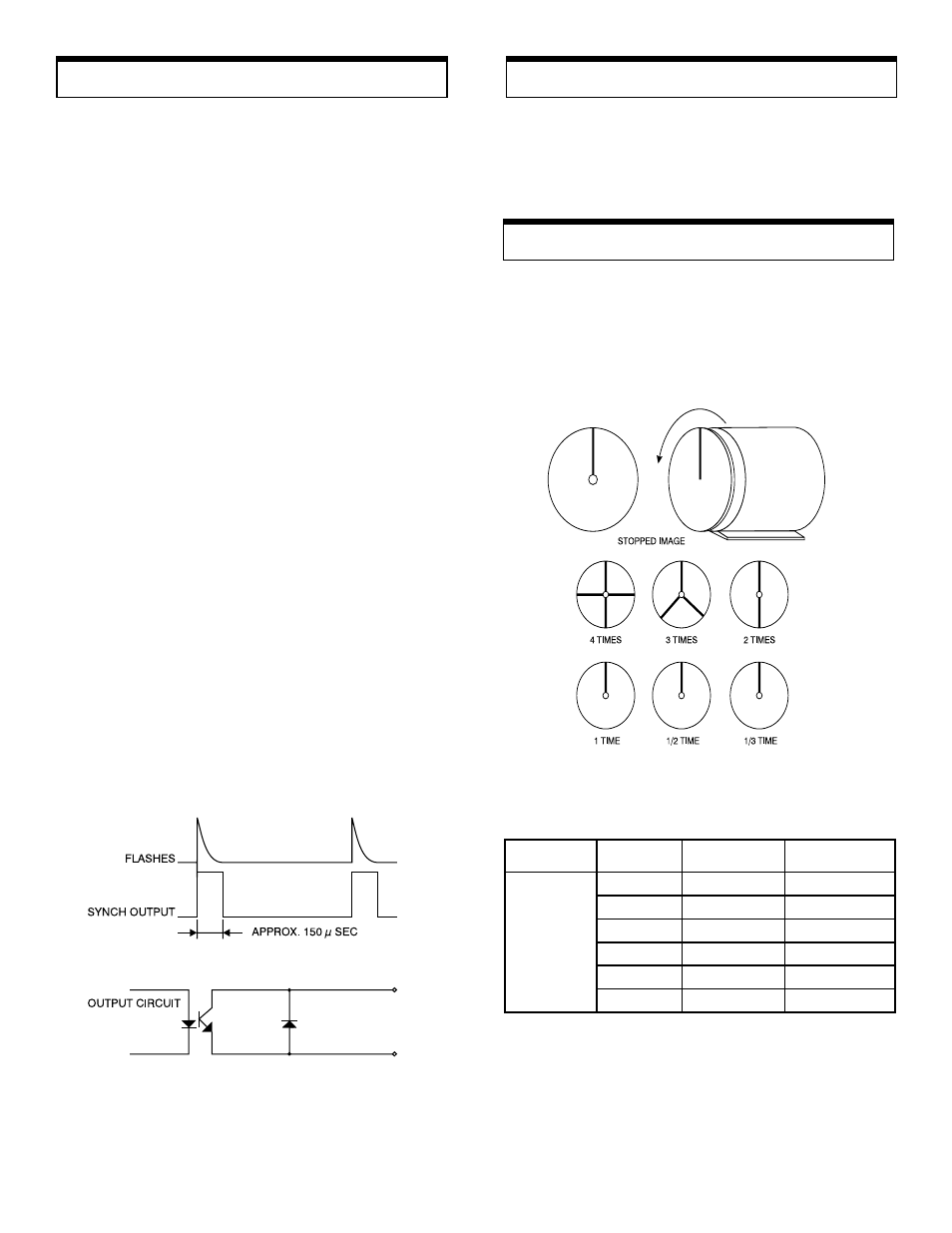

All strobes give the illusion of stopped motion when flashing

in submultiples of the true speed.

To obtain the correct rpm, turn knob from highest fpm

downward. When the first single image appears, read the

true rpm. To verify it, press "1/2". A single image will appear

again.

Memory

When the strobe is turned off and on again at a later time, it

will start to flash at the previous displayed rate regardless if

the setter has been moved or not.

Rotation of shaft

(rpm)

Number of

flashes (rpm)

Flashes/

rpm shaft

Number of

stopped images

at

1,500 rpm

6,000

4 times

4

4,500

3 times

3

3,000

2 times

2

1,500

1 times

1

750

1/2 times

1

500

1/3 times

1