Installation – KROHNE OPTITEMP Compact sensors User Manual

Page 19

INSTALLATION

3

19

OPTITEMP TRA-CXX

www.krohne.com

02/2014 - 4003290501 - MA OPTITEMP TRA-Cxx R01 en

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insert

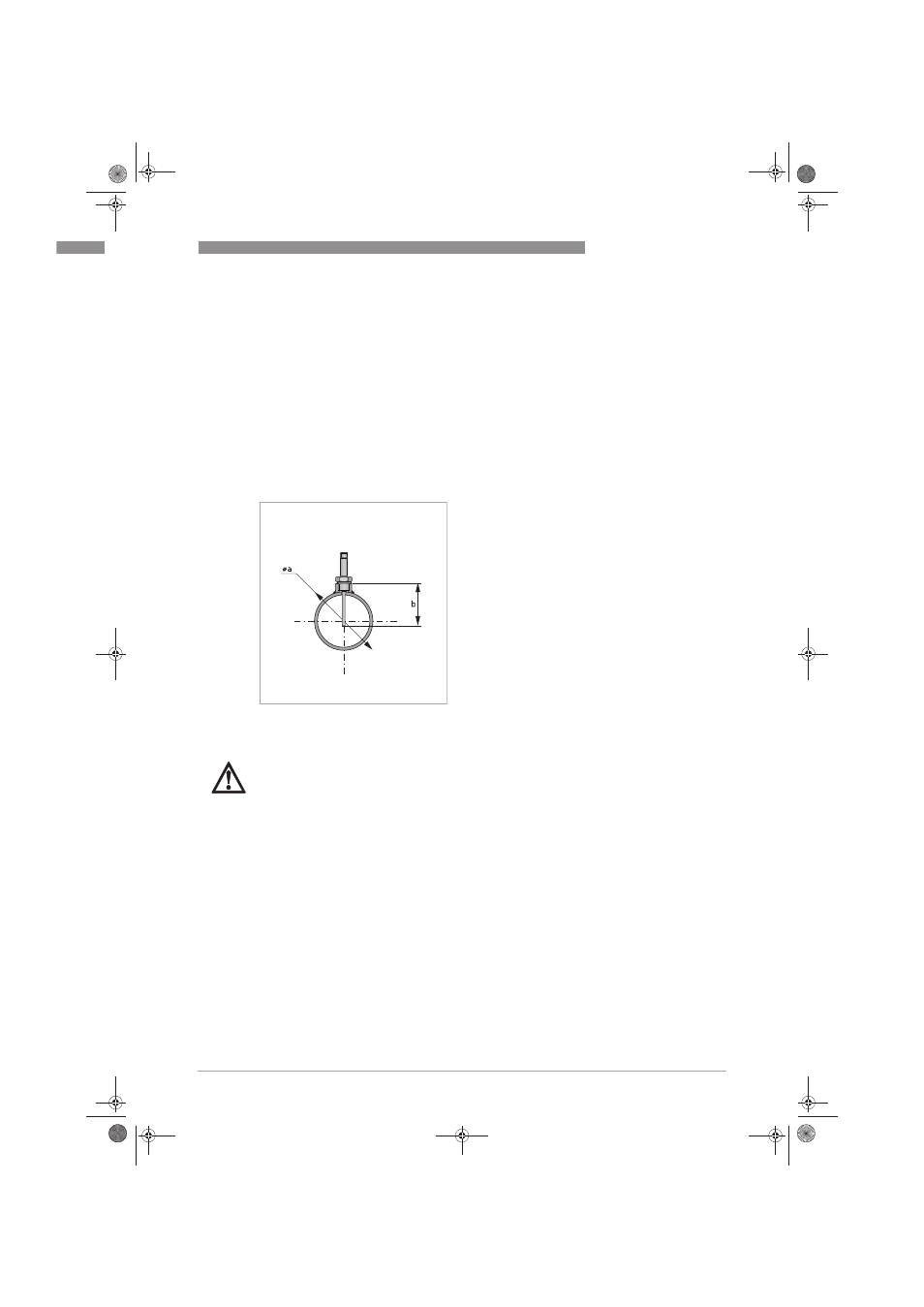

The "insertion length" of the thermowell or measuring insert refers to the distance from the seal

of the process connection (for G threads) or the bottom of the flange (for flange thermometers)

to the tip of the thermowell or sheath. This length determines how far the sensor projects into

the measured medium.

To avoid measurement errors, ensure that the insertion length ("b" in the drawing below) meets

the following requirement:

• Tubes with Ø < 300 mm / 11.8": thermowell tip should project past the middle of the pipe is

possible, if the flow velocity of the product allows it.

3.4.2 Other installation requirements

• A well-insulated pipeline or tank around the measuring point reduces the heat transfer and

the distorting influence of the ambient temperature.

• To avoid measurement errors caused by poor heat transfer, the measuring insert must

always be in contact with the bottom of the thermowell (this is normally guaranteed by filling

the thermowell with heat conducted compound).

• Choosing the right gasket for the process connection depends on the process conditions; the

manufacturer can thus only give the general recommendation that the gasket must comply

with the individual requirements of the measuring point (e.g. pressure, temperature,

chemically aggressive media, hygienic requirements).

Figure 3-2: Permitted insertion length

DANGER!

When a seal is damaged or incorrect, the medium may leak out, causing material damage or

bodily harm! It is the sole responsibility of the operator to select the right seal.

.book Page 19 Friday, February 7, 2014 9:17 AM