2 principle of operation – Detcon P-1000 User Manual

Page 7

P-1000

Portable Model 1000 H2S Analyzer

Rev. 1.0

Page 3 of 24

1.2 Principle of Operation

Sample gas is fed into the unit via the Process Sample Inlet port on the side of the unit. The flow of the gas is

regulated by the Rotameter, and passed through the coalescing filter to remove moisture and condensation.

The nominal flow rate should be 500cc/min. with a minimum flow rate of 200cc/min. and a maximum of

1000cc/min. The gas enters the ISM via the Flow-through Chamber where it is read by the sensor, and vented

to the atmosphere via an Activated Carbon Scrubber to the Vent Port. H

2

S gas diffuses through the capillary

diffusion barrier of the cell where detection is made by an electrochemical reaction at the surface of an

electrode called the sensing electrode. The controlling circuit maintains a small external operating voltage

between the sensing and counter electrodes of the proper bias and magnitude so that no current flows to or

from the reference electrode while its potential is maintained at the correct fixed voltage — usually ground.

The electrochemical reaction creates a change in current flow from the counter electrode to the sensing

electrode. This change in current is proportional to the gas concentration and is reversible. The quick

response of the sensor results in continuous and reliable monitoring of H

2

S Concentration.

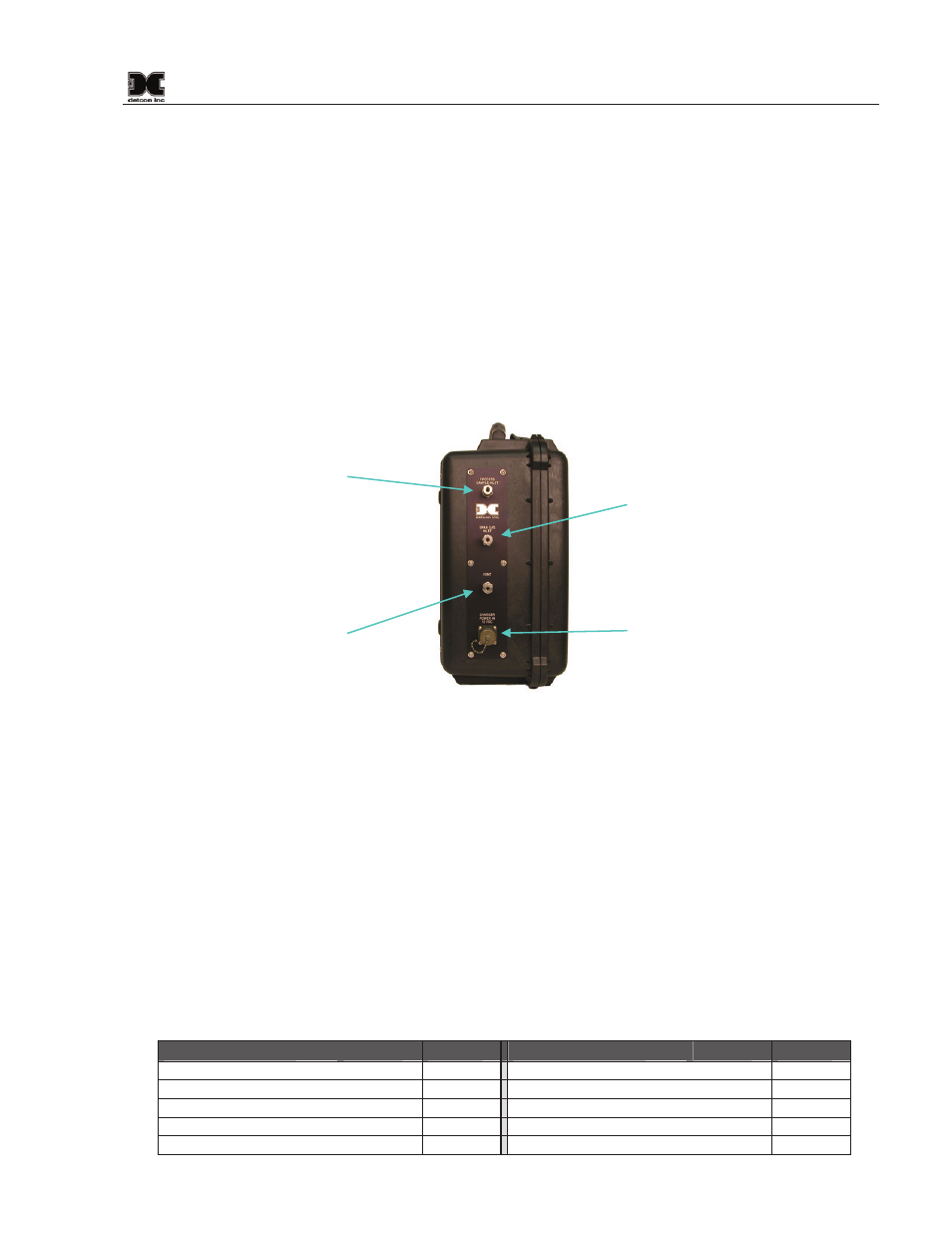

Process Sample Inlet

Port

Span/Zero Gas Inlet

Port

12VDC

Battery Charger Port

Vent Port

Figure 4 Gas Ports

Data from the sensor is exported by a HOBO Data Logger via a USB Port. The incorporation of the

HOBOware™ Software and a PC or Laptop complete the unit and allow the user to record the data in graphic

format that can be viewed via the HOBOware™ software. For more information, refer to the HOBOware™

Users Guide.

During Calibration the 3-way valve is placed in the CALIBRATE position and Cal Gas is fed to the sensor via

the Sample Gas Inlet Port.

1.2.1 Interference Data

UniTox™ Model 200 series electrochemical H

2

S sensors are subject to interference from some gases. This

interaction is shown in Table 1 as the relation between the amount of the interfering gas applied to the sensor,

and the corresponding reading that will occur. All measurements are in ppm unless otherwise noted.

Table 1 Gas Interference

Gas Name

Symbol

Cross

Gas Name

Symbol

Cross

Acetyldehyde C2H3O

n/d

Hydrocarbons C-H’s

n/d

Acetylene C2H2

n/d

Hydrocarbons (unsat.)

C-H’s (u)

n/d

Acrylonitrile C3H3N

n/d

Hydrogen H2

1%=<5

Alcohols Alcohols

n/d

Hydrogen Bromide

HBr

n/d

Amines Amines

n/d

Hydrogen Chloride

HCL

5=0