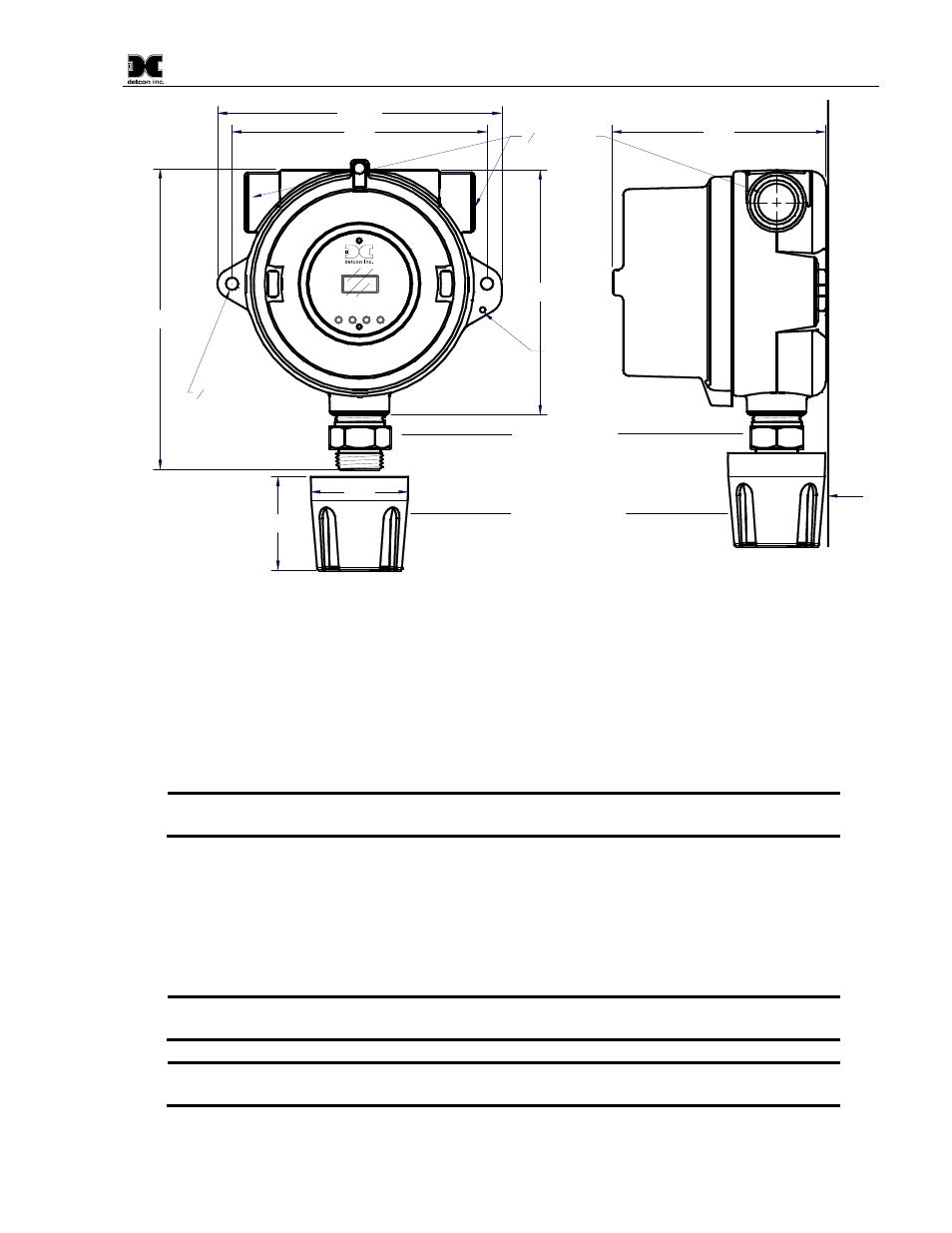

Electrical installation, Figure 6 typical outline and mounting dimensions, 5 electrical installation – Detcon TP-524D-HRT User Manual

Page 11: Wa ll, H2s sensor splash guard

Model TP-524D-HRT

TP-524D-HRT Instruction Manual

Rev. 0.3

Page 7 of 48

8-32 tapped

ground point

4.6"

3

4

NPT Ports

6.125"

5.5"

6.45"

1

4

" mounting holes

5.25"

W

a

ll

(o

r

o

th

e

r

m

o

u

n

ti

n

g

s

u

rf

a

c

e

)

H2S Sensor

Splash Guard

2"

2.1"

PGM

1

PGM

2

MODEL

TP-524D

HOUSTON, TEXAS

FLT

1

2

CAL

MicroSafe

H2S Gas Sensor

ALM ALM

TM

Figure 6 Typical Outline and Mounting Dimensions

2.5 Electrical Installation

The Sensor Assembly should be installed in accordance with local electrical codes. The sensor assemblies are

CSA/NRTL approved (US and Canada) for Class I, Division 1, Groups B, C, & D area classifications.

Proper electrical installation of the gas sensor is critical for conformance to Electrical Codes and to avoid

damage due to water leakage. Refer to Figure 7 and Figure 8 for proper electrical installation.

NOTE: If a conduit run exits the secondary port, repeat the installation technique shown in

Figure 7.

In Figure 7, the drain allows H

2

O condensation inside the conduit run to safely drain away from the sensor

assembly. The electrical seal fitting is required to meet the National Electrical Code per NEC Article 500-3d

(or Canadian Electrical Code Handbook Part 1 Section 18-154). Requirements for locations of electrical seals

are covered under NEC Article 501-5. Electrical seals also act as a secondary seal to prevent water from

entering the wiring terminal enclosure. However, they are not designed to provide an absolute watertight seal,

especially when used in the vertical orientation.

NOTE: A conduit seal is typically required to be located within 18" of the J-Box and Sensor

Assembly. Crouse Hinds type EYS2, EYD2 or equivalent are suitable for this purpose.

NOTE: The Detcon Warranty does not cover water damage resulting from water leaking into

the enclosure.