Flush piping, Filtration, Location – AW Gear Meters GEAR METERS User Manual

Page 5: Orientation, Flow direction

Positive Displacement Flow Meters

Operation and Installation Manual

4

Flush Piping

If feasible, flush piping to remove dirt and debris before installing flow meter.

Filtration

Filtration is recommended to prevent contaminants from entering the flow meter. See flow meter Data

Sheet for specific filter, including mesh weight and size.

Location

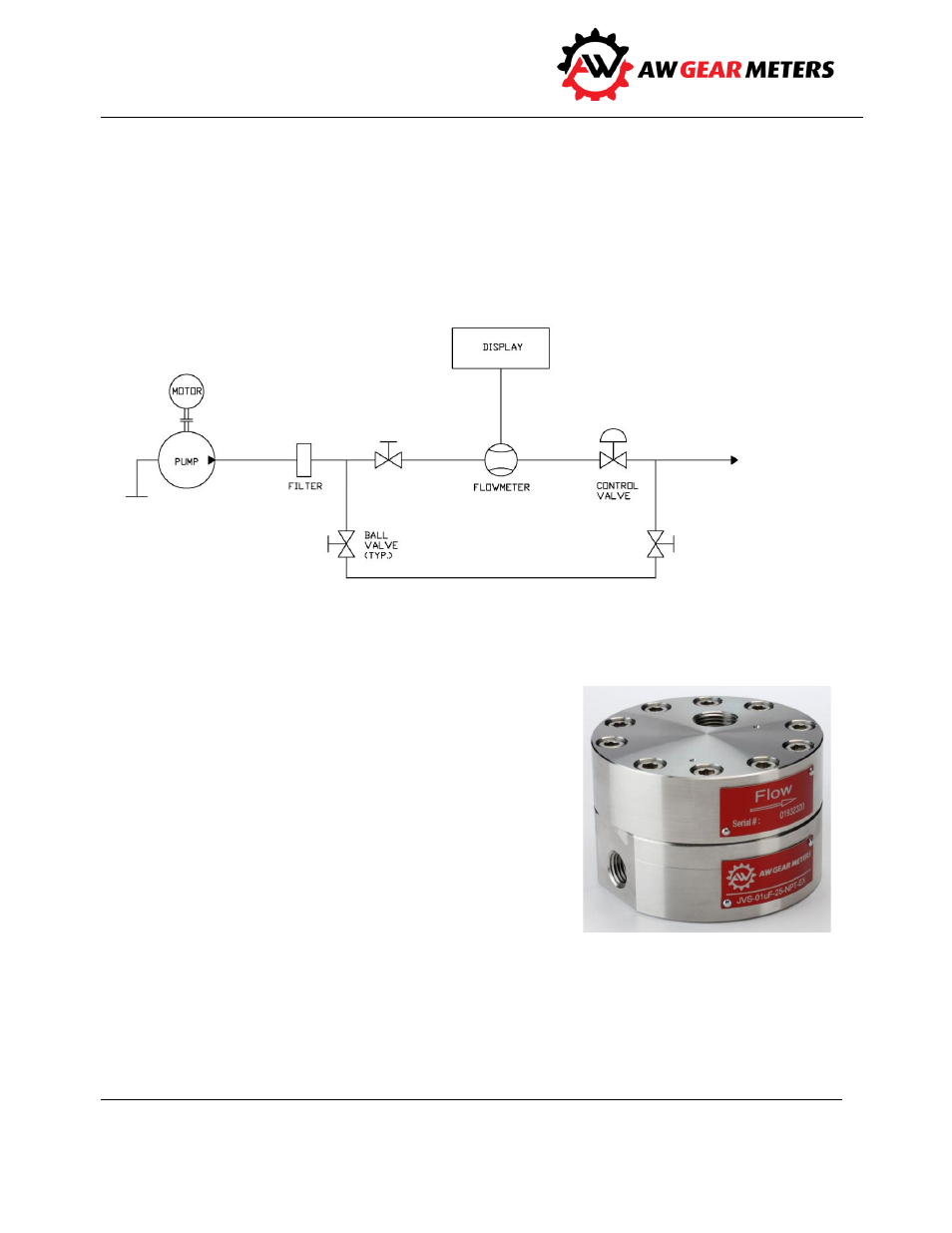

It’s best to install the flow meter upstream from control valves

and fluid regulators, if possible. See Figure 1.

Orientation

Positive displacement gear flow meters can be installed either a

horizontal or vertical (flow up) orientation. 2-3 psi of

backpressure is required to assure the meter is always full of

fluid. No straight run pipe is required upstream or downstream

of the meter.

Flow Direction

Flow direction is marked with an arrow on the flow meter.

See Figure 2.

Figure 1: Typical flow meter installation with bypass

Figure 2: Flow meter with direction of flow

marked with arrow