AW Gear Meters JV-60 KL User Manual

Maintenance guide for the jv-60 kl flowmeter

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: [email protected]

REV. 05/24/12 JV60KL.DOC

MAINTENANCE GUIDE FOR THE JV-60 KL FLOWMETER

Cleaning, inspecting or repairing an JV-60 KL gear flow meter is easily

accomplished by following the procedures below.

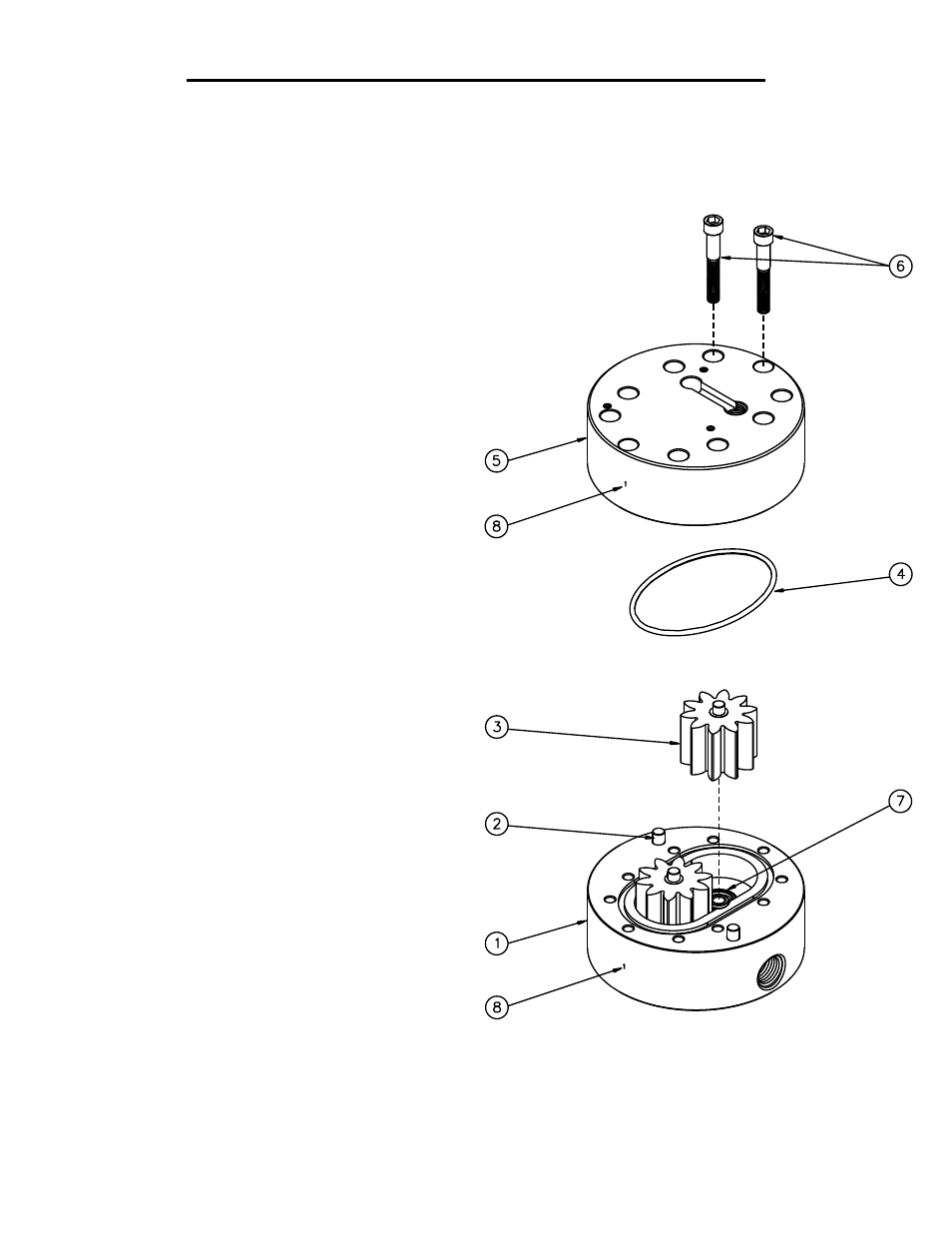

1. Remove the pickup sensor (not shown) from the flow meter body (5).

2. Remove the hex bolts (6) with a 3/16" key wrench.

3. Re-engage 2 opposing bolts diagonally from each

other by a few threads to avoid stress on the

shafts and locator pins during housing separation.

4. Holding the upper housing (5), gently tap the

opposing bolts (6) to separate the lower housing

(1). Do not use chisels or screwdrivers to split

and pry apart the housings - this may damage

the gears and locating pins.

5. After separation, inspect the gears (3) and

bearings (7). Inspect and clean the gears taking

care not to dislodge the bearings (7) located in the

housing. The meter should be returned to the

factory for any bearing repairs. Note: Meters

purchased before May, 2001 may have shims

installed. Refer to drawing #JVM6900B for this

model.

6. After cleaning, all parts can be reinserted into

their previous positions. Check for free & easy

rotation.

7. Replace O-ring (4) if deformed.

8. Keep meter housings parallel during reassembly

and align index marks (8). Both locating pins

must be in place (2).

9. Replace hex bolts and slowly tighten to at least

15 Nm. (This is hand tight). Do not force the

housing closed. Do not use a hammer. Over

tightening will not cause damage but may restrict

operation if internal surfaces are not completely

clean.

10. After reassembly, gently blow air into meter so

gears spin. This should be clearly audible given a

moderate background noise level.

11. Clean any debris from the pickup port & hand

tighten the pickup sensor. Avoid over tightening

as this may damage the meter.

Do not over tighten sensor *

The bearings should be lubricated prior to storage.

Never allow contact with water without immediately

drying and lubricating after use.