Trouble-shooting guide, Positive displacement flow meters – AW Gear Meters GEAR METERS User Manual

Page 14

Positive Displacement Flow Meters

Operation and Installation Manual

13

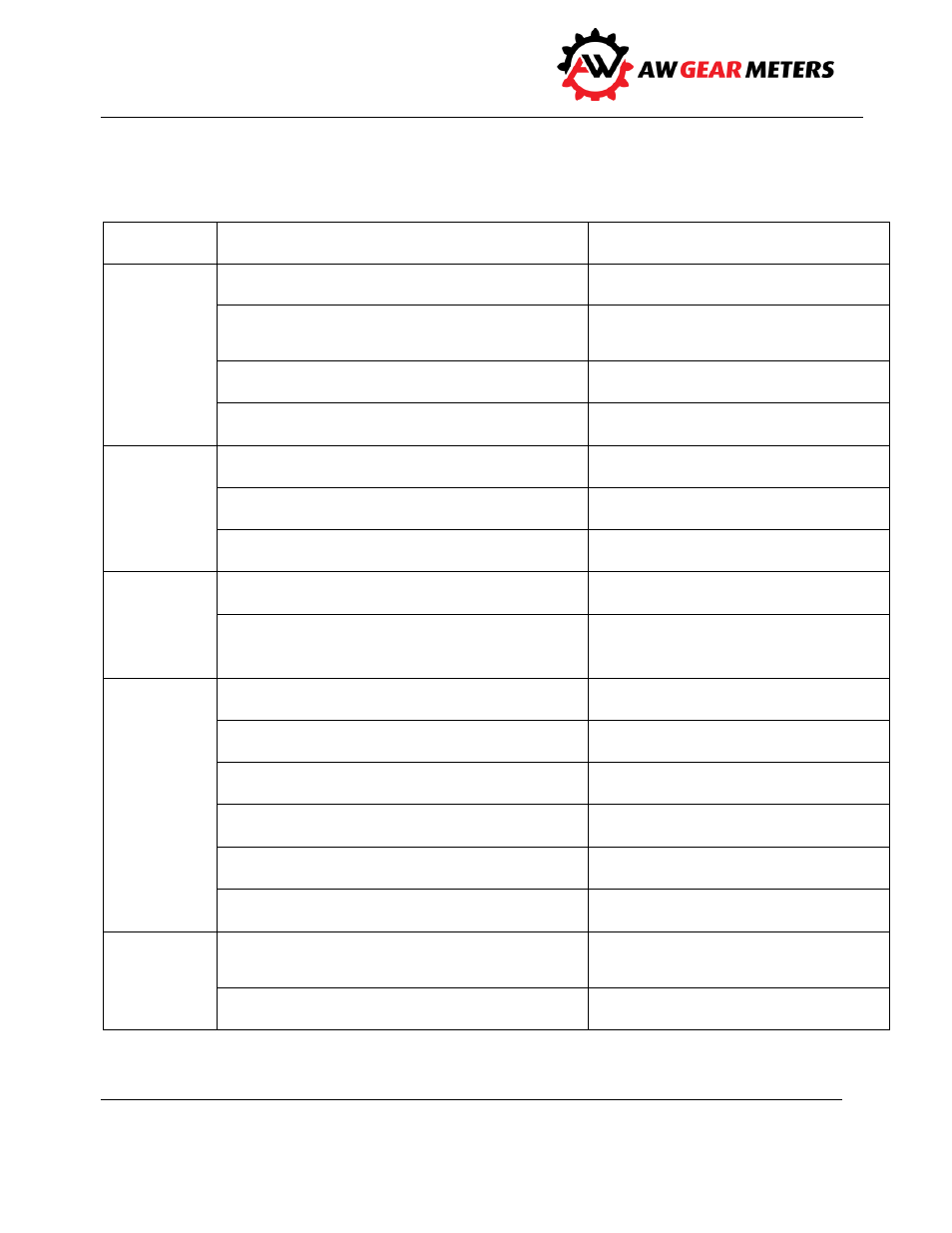

Trouble-Shooting Guide

PROBLEM

POSSIBLE CAUSE

SOLUTION

Flow meter

indicates

lower than

actual.

Viscosity of fluid is less than 30 cst.

Decrease the k-factor by percent error.

Excessive pressure differential across flow meter,

causing gears to bind.

Reduce flow rate, reduce fluid viscosity.

Debris in measuring chamber.

Clean flow meter; change or add filter.

Upper housing has dimple from over tightening

sensor.

Replace upper housing.

Flow meter

indicates

higher than

actual.

Air in lines.

Add air eliminator.

Electro-magnetic interference.

Ground flow meter and all electronics.

Reverse fluid flow.

Add check valve.

Indicator

shows flow

when there is

no flow.

Fluid oscillates.

Check pump, add check valve, increase

backpressure.

Electro-magnetic interference.

Ground flow meter and all electronics.

Use shielded cable and relocate away

from electrical noise.

No flow

indication.

No fluid flow.

Check pump.

Debris in measuring chamber or gears.

Clean flow meter, change or add filter.

Sensor not installed properly.

Check sensor is installed to hand tight.

Review sensor guide.

Faulty wiring.

Check sensor connection and readout

connection.

Faulty sensor.

Replace sensor.

Upper housing has dimple from over-tightening

sensor.

Replace upper housing.

Erratic

system

indication.

Ground loop in shielding.

Ground shield one place only. Re-route

cables from electrical noise.

Pulsating fluid flow.

Add pulse dampener.