AW Gear Meters ZHM Series User Manual

Zhm series flow meter maintenance guide

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awgearmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: [email protected]

REV. 03/09 ZHM.DOC

ZHM Series Flow Meter Maintenance Guide

Cleaning, inspecting or repairing a ZHM Series gear flow meter is easily accomplished

by following the procedures below.

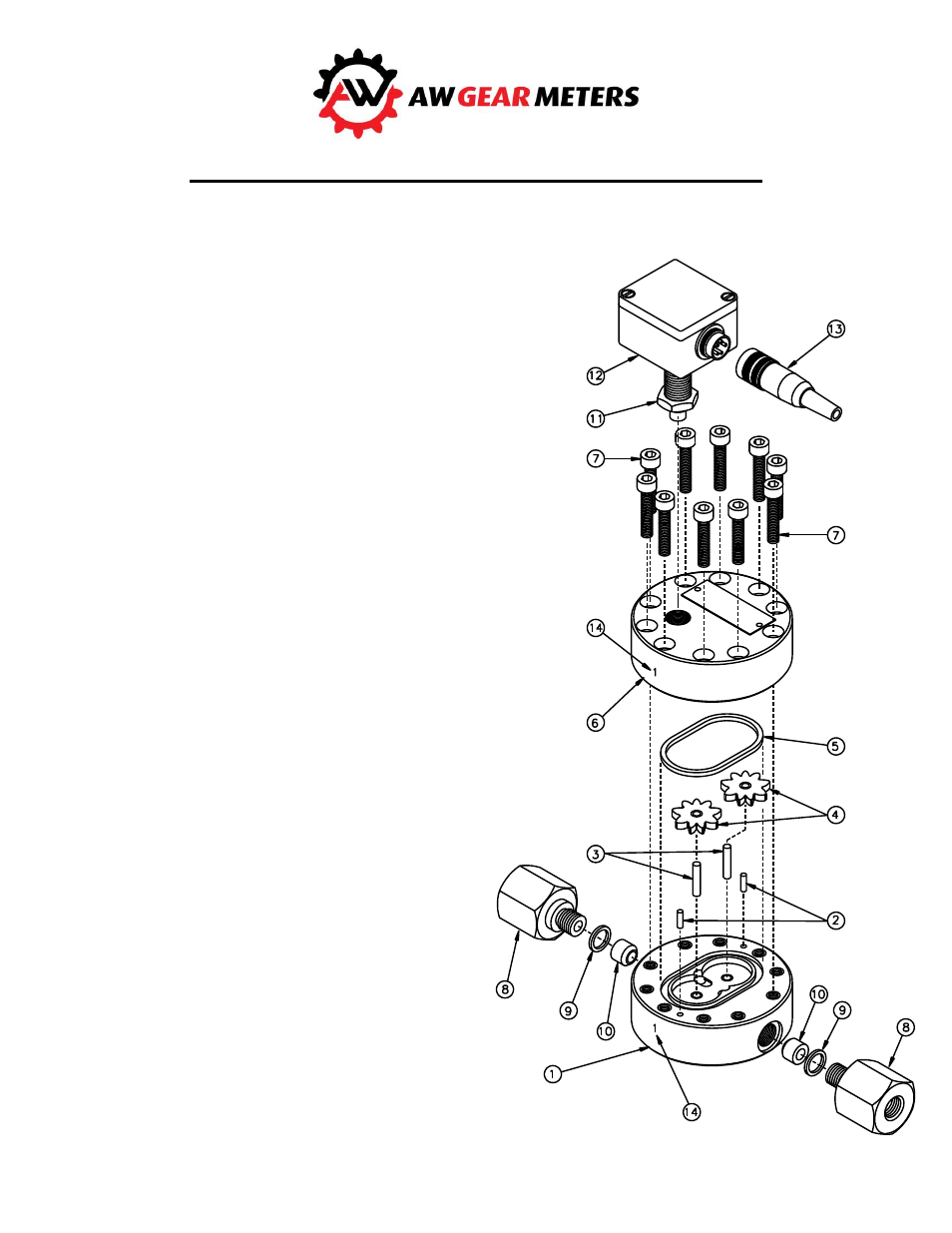

- Remove the Pickup (12) from the flow meter body (6). (The

model HESK1 sensor is shown here) Some models have a dual

sensor, IGO6HD-XX, which has 2 built-in pickups, and is

attached by two sunken, hex-head screws.

- Note index marks (14). If symbols are absent, mark the body positions.

- Loosen the hex bolts (7) with a 5 mm key wrench - ZHM-04/8mm,

ZHM 05+06/10mm, ZHM 07/14mm. Remove the bolts except for two

opposing bolts (7)which should remain engaged by a few threads to

avoid damaging the shaft when the 2 flow meter housings separate.

- Holding the upper housing (6), gently tap the opposing bolts (7) to

separate the lower housing (1). Do not use chisels or screwdrivers

to split or pry apart the housings - this may damage the carbide

parts.

- After separation, remove and inspect the gears (4) & shafts (3).

Clean with solvent and a small brush. The gears should revolve

freely on the shafts.

- After cleaning all parts completely, the gears & shafts can be

reinserted. Check for free and easy rotation.

- Replace the O-ring (5) if deformed.

- Keep meter housings parallel during reassembly. Both locating

pins must be in place (2). Align index marks (14).

- Replace hex bolts as follows:

ZHM 01-03 - 15 Nm. *(This is hand tight).

ZHM 04 - 75 Nm.

ZHM 05/06 -130 Nm.

ZHM 07 -300 Nm.

- Over tightening will not cause damage but may restrict

operation if internal surfaces are not completely clean.

- After reassembly - a brief air blast will spin the gears.

This should be clearly audible given a moderate

background noise level.

- Clean any debris from the pickup port, insert Hall Sensor

all the way, and then back off 1/4 revolution and tighten

lock nut. * Do not over tighten *

- With the dual sensor, the electrical connector should

point in the flow direction after reassembly. The sensor should

fit flush on the meter body with good hex screw alignment.

- Optional PTFE space fillers (10) are available to fill

space behind the conversion fittings when multi-colored

materials are being metered.