AW Gear Meters JVK-60 SERIES User Manual

Maintenance guide for the jvk-60 series flow meter

AW Gear Meters 8809 Industrial Drive, Franksville, WI 53126 web: www.awflowmeters.com

Tel: 262-884-9800 Fax: 262-884-9810 Email: [email protected]

REV. 5/24/12 JVK-60 + IR-P.DOC

MAINTENANCE GUIDE FOR THE JVK-60 SERIES FLOW METER

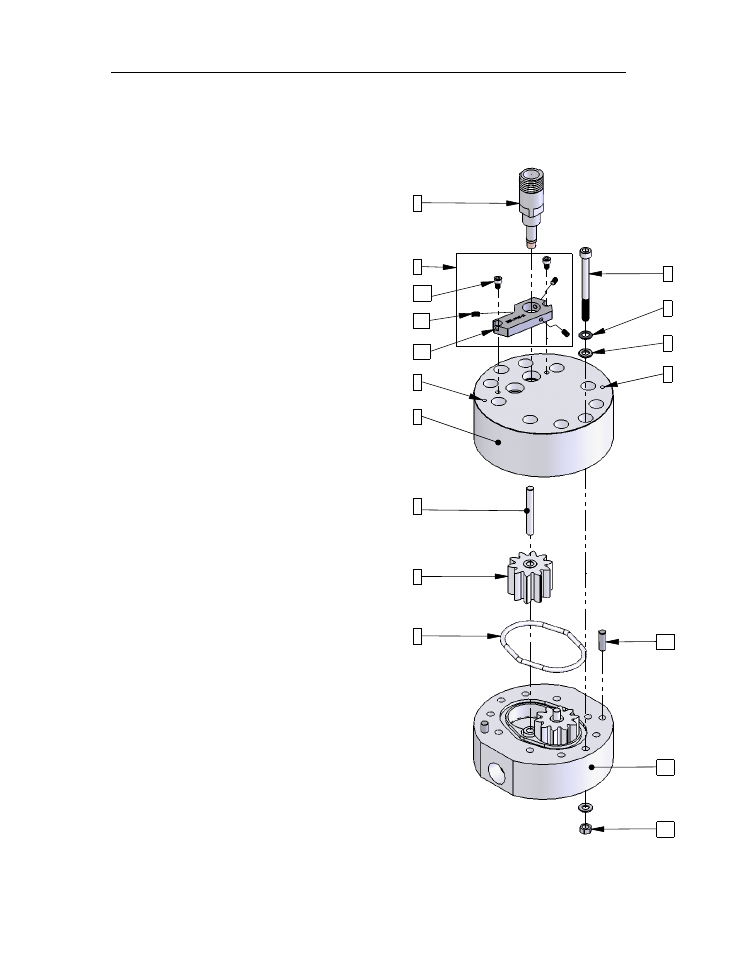

(Shown w/ IR-P Sinking Sensor)

* Cleaning, inspecting and/or replacing parts can be done by following the procedure below.*

Read the entire procedure before taking apart the meter. Be careful when handling parts!

1) Remove the sensor (1) from the meter by loosening the

3 set screws (2c) with a 3mm hex key.

2) Remove the Sensor Adapter (2a), by removing the M4

Screws (2b).

3) Loosen the Socket Cap Screws (3) from the nuts (12)

by using a 5mm hex key for the bolts and a 10mm

socket for the nuts. Also, remove the spring washers

(4) and flat washers (5).

4) Separate the upper and lower housings (6) & (11).

Insert 2 hex keys or similar tools into the 2 holes (*).

Using a small hammer and holding the upper housing,

lightly tap the hex keys to separate the housings.

Alternate tapping the hex keys to avoid damage to the

locating pin holes. **

DO NOT use a

screwdriver or other tools to pry apart

the housings as this can cause permanent

damage to the flow meter bodies and

internal parts and will void the

warranty.**

5) Once the housings are separated:

a. Remove the gears (8). Inspect the gears and

clean if needed. Be careful not to drop the

gears as this will damage them.

b. Remove the shafts (7), inspect them and clean

them if needed.

c. Clean out the cavity in the upper and lower

housings and inspect them for damage and/or

wear.

d. Replacing the PTFE o-ring (9) is

recommended to ensure sealing once

reassembled.

6) To reassemble the meter:

a. Insert the o-ring (9) into the o-ring groove.

b. Insert the shafts (7) back into the shaft holes.

c. Insert the gears back into place. Make sure

they are able to freely spin.

d. Rejoin the upper and lower housings together,

using the locating pins (10) to guide the

positioning of the housings.

e. Reinsert the bolts, washers and nuts. Torque

down bolts to 3.5 ft/lbs. (See diagram on

next page for recommended order to

tighten bolts.)

f. Reinstall the sensor adapter (2) and sensor (1).

Do Not Over Tighten the screws (3) as you

can strip the threads in the meter body.

ENGLISH

. XXXX +/- .0005

.XXX +/- .001

.XX +/- .005

FRAC. +/- 1/64

ANG. +/- 1/2 DEG

SURFACE FINISH: 64 MAX

TOLERANCES UNLESS NOTED

THIS PRINT, INCLUDING THE INFORMATION

CONTAINED IN IT IS THE PROPERTY OF AW COMPANY.

IT IS CONSIDERED PROPRIETARY IN NATURE AND

MAY NOT BE USED OR DISCLOSED OUTSIDE OF

AW COMPANY, EXCEPT UNDER PRIOR WRITEN

AGREEMENT. ANY MODIFICATIONS MADE TO OR

COMMENTS WRITTEN ON THIS DRAWING

BY UNAUTHORIZED PERSONNEL WILL VOID

THIS DRAWING. ALL DIMENSIONS SHOWN

ARE SUBJECT TO CHANGE WITOUT NOTICE.

AW COMPANY USE ONLY

TITLE: --

PART NUMBER: --

DRAWING NUMBER: Exploded - 120407

DRAWN BY: --

REV:

DATE: 12/4/2007

CHECKED BY: --

PAGE: 1 OF 1

SCALE: 1:10

AW COMPANY

8809 INDUSTRIAL DR.

FRANKSVILLE, WI 53126

TEL. # (262) 884-9800

FAX. # (262) 884-9810

PURCHASED PART

NOTES:

MATERIAL: --

1.

BREAK EDGES MAX .005"

2.

ALL PARTS MUST BE CLEAN AND FREE OF PARTICLES.

3.

REV.

DESCRIPTION

DATE

BY

1

2

2a

2b

2c

3

4

5

6

7

8

9

10

11

12

*

*