10) multi jig tormek® svs-50 set up – Work Sharp WS3000 Tool Bar Attachment User Manual

Page 9

(10) Multi Jig Tormek® SVS-50 Set Up

1

Place Tool Bar in Position ‘B’.

Grind

Angle

30°

38°

47°

TSO

Setting

B

B

B

Height

Setting

1

2

3

Tool Rest

Postition

B

B

B

Roughing Gouge

Grind

Angle

30°

38°

47°

TSO

Setting

B

B

B

Height

Setting

1

2

3

Tool Rest

Postition

B

B

B

Parting Tool

Grind

Angle

31°

39°

48°

58°

TSO

Setting

B

B

B

B

Height

Setting

0

1

2

3

Tool Rest

Postition

B

B

B

B

Skew Chisel

Tool Set Up

Set Up Reference Charts

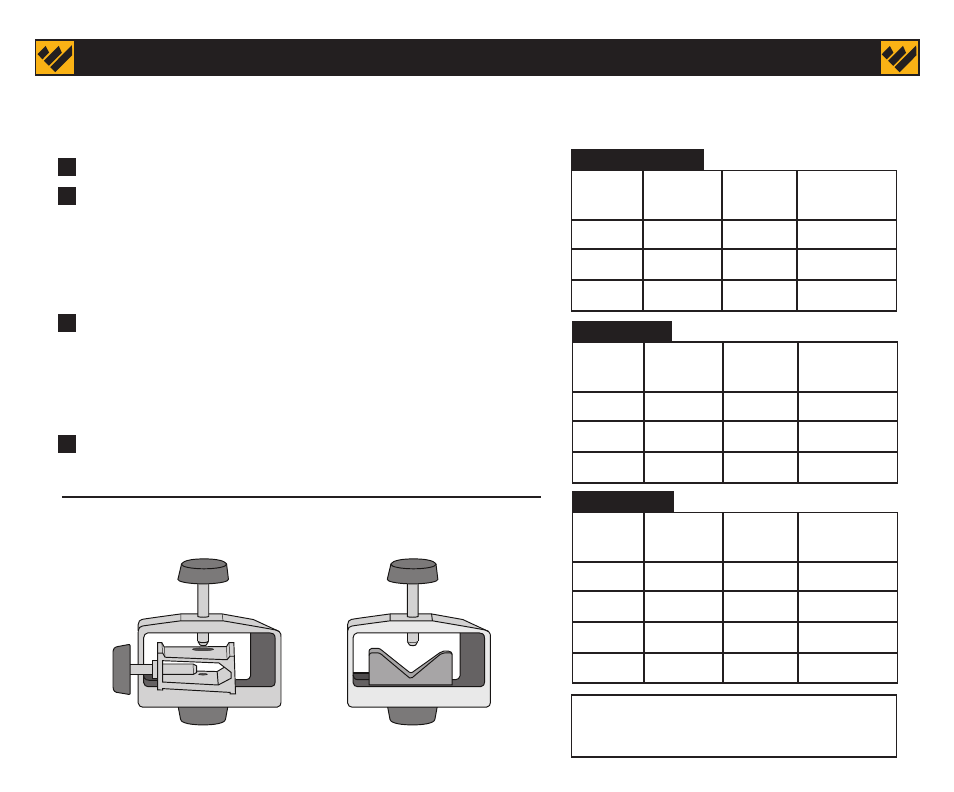

2

Nest the ‘Vee Plate’ fixture or ‘Skew Tool’

fixture into the SVS-50 sharpening jig

• Use Vee Plate fixture for Roughing Gouges and

Parting Tools.

• Use Skew Tool fixture for Skew Chisels.

3

Clamp tool into the jig to the proper TSO setting.

Set your Tool Bar ‘H’ setting.

See Set Up Reference Chart specific to respective tool for

guidance. (on right)

Optional: Progress through the abrasive grits to refine the surface

finish of your tool. Use the same settings and technique for all

abrasives.

4

Using the coarse P80 grit abrasive, sharpen the

entire bevel in one smooth pass.

Note: One turn (+/-) of the micro adjust

nut effects grind angles 2.5-3° or .080 in

of the Tool Bar Height (H)

Skew Tool Fixture

Vee Plate Fixture

Tip: Reference Tormek® instructions for more detail on jig set up and use.