Van Air Systems PLD 8-14.5 / 36-14.5 User Manual

Page 3

PAGE 3

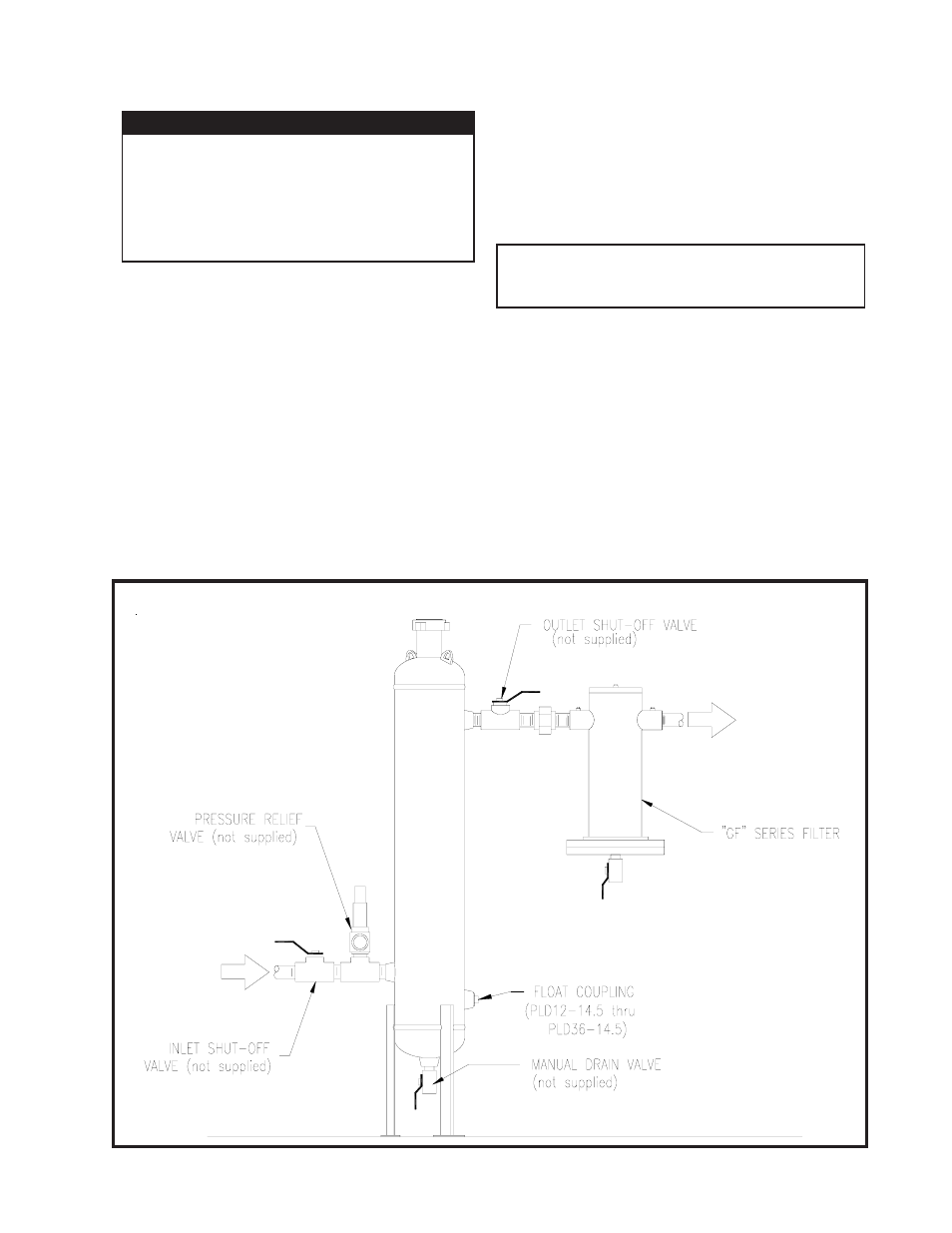

FIGURE 2-A RECOMMENDED INSTALLATION

2.3 INLET AND OUTLET PIPING

NOTE

Inlet and outlet shut-off valves will make start-up

and addition of desiccant easier.

Two shut-off valves should be installed (not furnished

with dehydrator)--one at dehydrator inlet and another at

dehydrator outlet. See Figure 2-A Recommended

Installation.

Connect the inlet piping and outlet piping as shown in

Figure 2-A.

2.4 DRAIN VALVE

Install a drain valve (not furnished with dehydrator) in the

drain coupling at the bottom of the tower (except on

PLD8-14.5). A float/auto drain valve system is available.

Contact Van Gas for details.

IMPORTANT

COMPLY WITH ALL FEDERAL, STATE, AND

LOCAL REGULATIONS CONCERNING IN-

STALLATION OF NATURAL GAS SYSTEMS.

COMPLIANCE WITH AND KNOWLEDGE OF

ALL REGULATIONS IS THE RESPONSIBIL-

ITY OF THE INSTALLER.

Install a pressure relief valve in the up-stream

piping (relief valve not furnished). A relief valve

must be installed to conform with the ASME

Boiler and Presssure Vessel Codes, Section VII,

Division 1 UG-125, Paragraph (1) and OSHA

standards. Also comply with all applicable

Federal, State and Local codes.

2.2 PIPING & ANCILLARY EQUIPMENT

Make sure that the gas temperature is not over the maxi-

mum for the desiccant being used. If gas temperature is too

high, cool it prior to the dehydrator.

Mount the dehydrator on a level surface capable of sup-

porting the weight of the vessel, such as a cement pad or

a skid.

2.5 AFTERFILTER

Van Gas "GF" Series Filters can be installed downstream

of the dehydrator to remove particulate contamination

from the natural gas. Contact Van Gas for details.