0 purpose, 0 installation, 1 location – Van Air Systems PLD 8-14.5 / 36-14.5 User Manual

Page 2: Maximum capacities - mscfd

PAGE 2

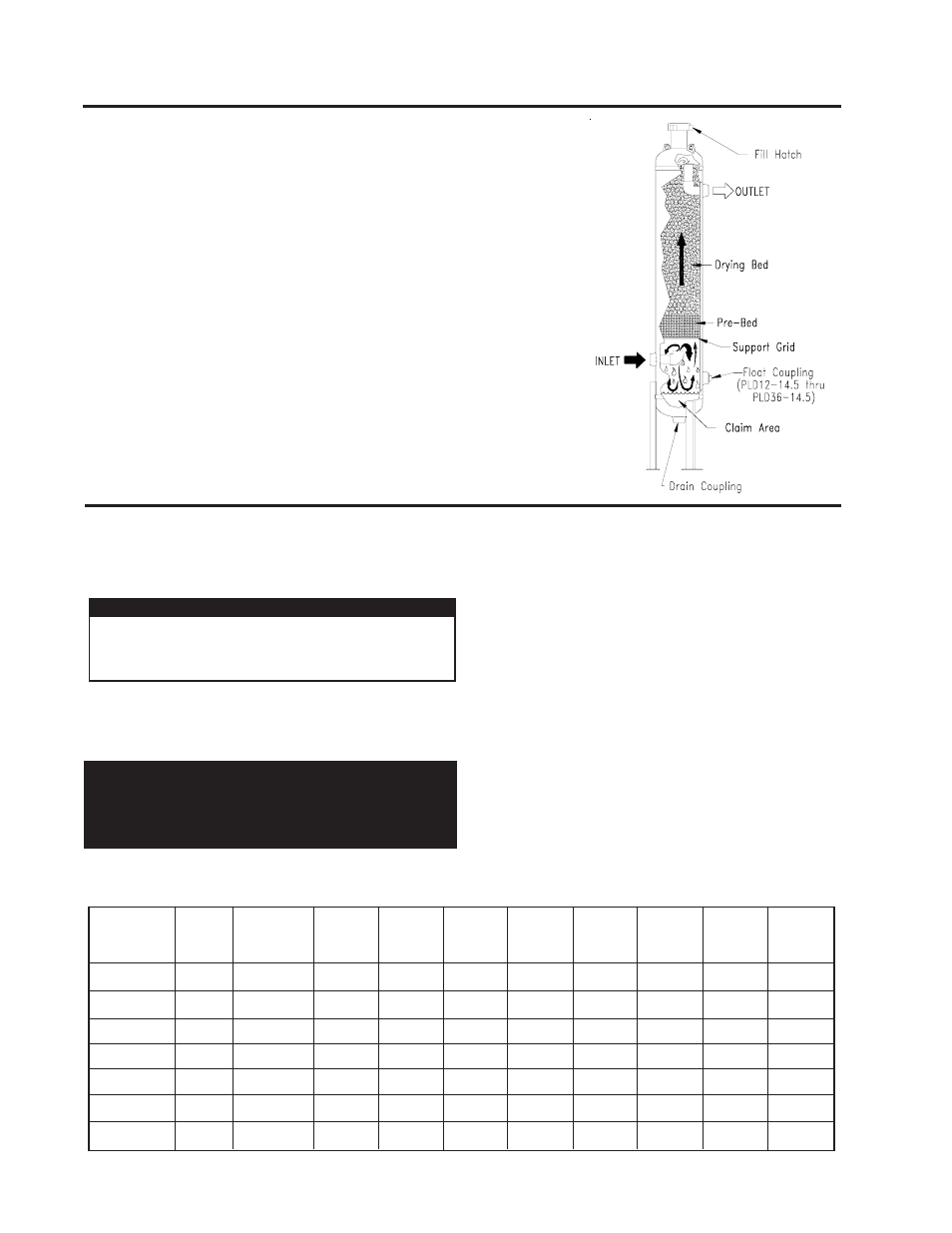

1.0 PURPOSE

MODEL

PLD8-14.5

PLD12-14.5

PLD16-14.5

PLD20-14.5

PLD24-14.5

PLD30-14.5

PLD36-14.5

2.0

INSTALLATION

2.1 LOCATION

CAPACITY: The chart below indicates the maximum flow

rate through the dehydrator for a 24 HOUR period. To

calculate the capacity for a rate per minute just multiply the

MSCFD RATE (from chart ) by 0.6944 example:

A PLD12-14.5 operating at 100 PSIG has a maximum

MSCFD rate of 119. To figure the SCFM multiply 119

MSCFD x 0.6944 which equals 83 SCFM

NOTE: This is the MAXIMUM instantaneous flow that can

be processed through the dehydrator without deteriora-

tion of the drying performance.

OPERATING PRESSURE: More gas can be processed

through the dehydrator at higher pressures. Locate the

dehydrator at the highest practical pressure, but do not

exceed the maximum rated working pressure of the dehy-

drator. Refer to the capacity chart located below.

AFTERCOOLING: If the gas being processed has been

compressed mechanically, an aftercooler, finned tubing or

extended run of piping will usually be necessary to reduce

the inlet gas temperature to the dehydrator.

MAXIMUM CAPACITIES - MSCFD

1,000 STANDARD CUBIC FEET PER DAY

1300

PSIG

735

1363

2158

3558

5128

7968

13655

1200

PSIG

679

1259

1994

3287

4738

7362

12616

1100

PSIG

623

1156

1830

3017

4348

6756

11578

1000

PSIG

567

1052

1666

2746

3958

6150

10539

750

PSIG

428

793

1255

2069

2983

4635

7943

100

PSIG

64

119

188

310

447

695

1191

MAXIMUM

WORKING

PRESSURE

1450 PSIG

1450 PSIG

1450 PSIG

1450 PSIG

1450 PSIG

1450 PSIG

1450 PSIG

PART

NO.

80-1477

80-1442

80-1483

80-1482

80-1484

80-1485

80-1486

ALWAYS PROCESS THE GAS THROUGH THE

DEHYDRATOR AT THE LOWEST TEMPERA-

TURE AND THE HIGHEST PRESSURE

.

IMPORTANT

CAUTION

The gas temperature should not exceed:

100°F for GASDRY PRIME

80°F for GASDRY PEAK

100°F for GASDRY MAX

1400

PSIG

791

1467

2322

3829

5518

8574

14694

A Pipeline Dehydrator removes the water vapor (humidity) present in the

gas stream. The process cleans and dries the gas as it flows through the

vessel which is filled with a special drying agent (desiccant). The

dehydrator operates automatically. There are no moving parts and no

external source of power is required.

"Wet" natural gas enters the lower portion of the dryer where liquid water

and solid particles are separated by gravity and fall to the bottom of the

vessel. The gas moves upward through the prebed and drying bed of

Van Gas desiccant tablets. The tablets attract and absorb moisture from

the gas as it flows through the desiccant bed. The tablets dissolve

gradually as they absorb the moisture and the liquid falls to the bottom of

the vessel. The liquid run off in the prebed creates an extended surface

area capable of removing additional moisture from the gas. This con-

serves the absorbent desiccant tablets. The "dry" natural gas flows

through the dryer outlet.

The solution of dissolved desiccant and water that falls into the claim

area at the bottom of the vessel must be drained regularly to prevent the

vessel from flooding. An automatic drain valve can be installed to

prevent the vessel from flooding.

The ability of a dehydrator to dry natural gas is dependent

on the correct location of the unit. Temperature and pres-

sure are the keys to selecting the proper location.

INLET TEMPERATURE: Lower inlet gas temperatures will

result in lower moisture content at the dehydrator outlet.

Locate the dehydrator at the point where temperature is the

lowest.

1450

PSIG

819

1519

2404

3964

5714

8877

15213