1 dryer specifications – Van Air Systems HL-2500 User Manual

Page 3

PAGE 3

DIMENSIONS AND SPECIFICATIONS

SECTION 3

3.1 DRYER SPECIFICATIONS

APPROXIMATE WEIGHT: 5800 lbs (with desiccant installed)

DIMENSIONS

.............. See SECTION 3.2

IN/OUT CONNECTION:

4" - 150# R.F. Flange

VESSELS (desiccant towers)

Construction .................. Manufactured to the ASME CODE, Section VIII, Division 1.

Vessels stamped "U" symbol.

Design Pressure ........... 150 PSIG

Design Temperature ..... -20 to 300

O

F

PIPING

Threaded fittings: ANSI B16.3

Threaded unions ANSI B16.39

Flanges: ANSI B16.5

Weld fittings: ANSI B16.9

Pipe: Carbon steel, Schedule 40

VALVES

Inlet ............... One (1) Proprietary 3-Way piloted shuttle valve

Outlet ............. Two (2) Check valves, metal hinge type

Purge ............. Two (2) Normally closed, diaphragm type valves

CONTROL AIR FILTER

Construction .................. Zinc housing

ELECTRICAL

Standard 115 Volt .......... 115-120V/1PH/60Hz

Optional 230 Volt ........... Main power: 220-240V/1ph/50-60Hz

Control Power: Transformed to 115V-120V/1ph/50-60Hz, on EMCON II only.

DESICCANT

Material .......................... Activated Alumina, 1/8" (2-5mm) Bead type

Quantity Per Tower:

1450 lbs

OPERATING CONDITIONS

Inlet Air Pressure ...........................MIN 60 PSIG ..........MAX 150 PSIG

Inlet Air Temperature ..................... MIN 40

O

F ............... MAX 120

O

F

Ambient Air Temperature ............... MIN 40

O

F ............... MAX 120

O

F

RATED INLET CONDITIONS

Inlet Air Pressure ........................... 100 PSIG

Inlet Air Temperature ..................... 100

O

F

Relative Humidity (saturation) ....... 100% RH

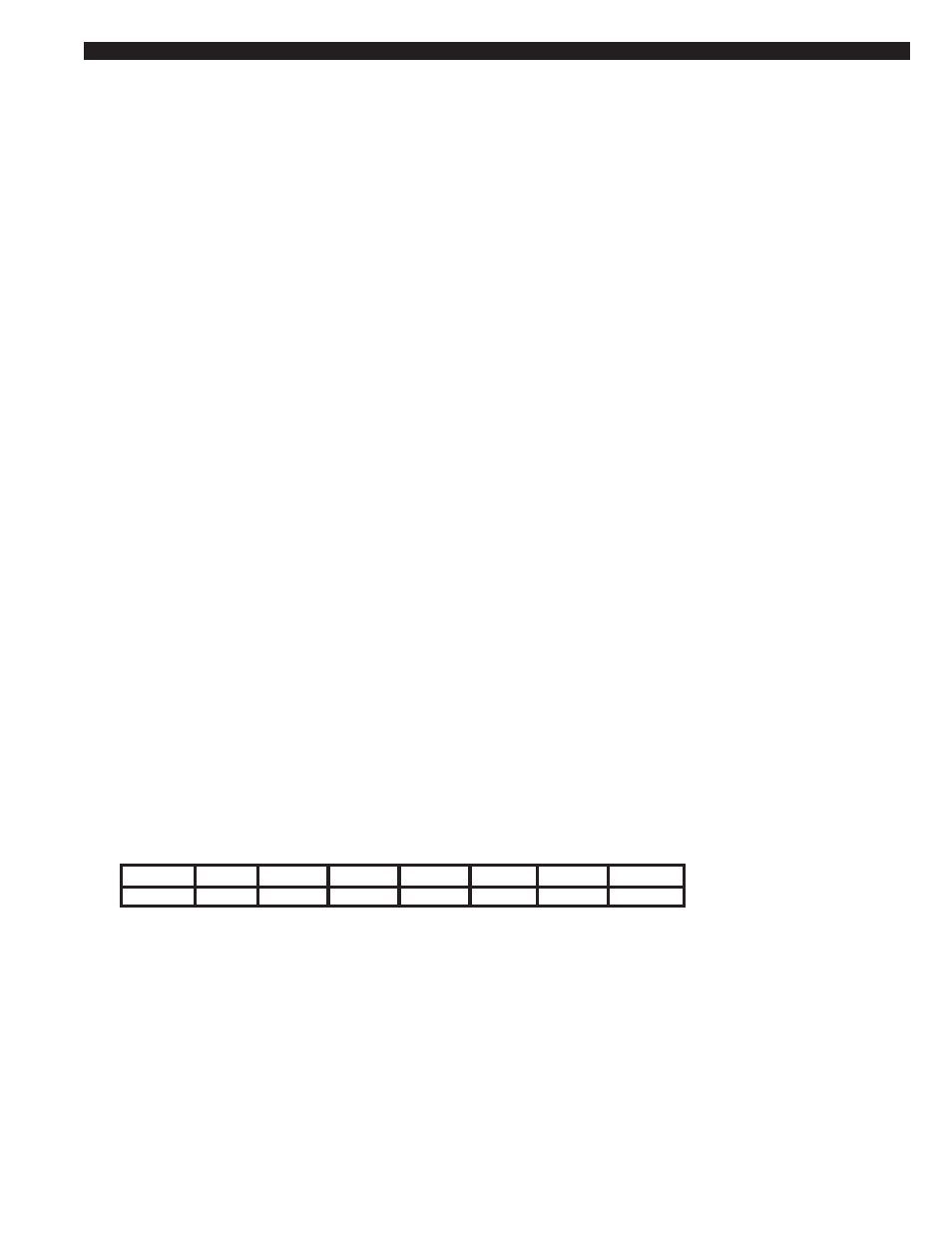

FLOW CAPACITIES (SCFM) at various pressures (100

0

F)

60 PSIG

80 PSIG

100 PSIG

110 PSIG

125 PSIG

140 PSIG

150 PSIG

HL-1500

1628

2064

2500

2607

2759

2903

2996