Van Air Systems HL-2500 User Manual

Page 14

PAGE 14

USING THE CYCLE SAVER CONTROL

SECTION 8

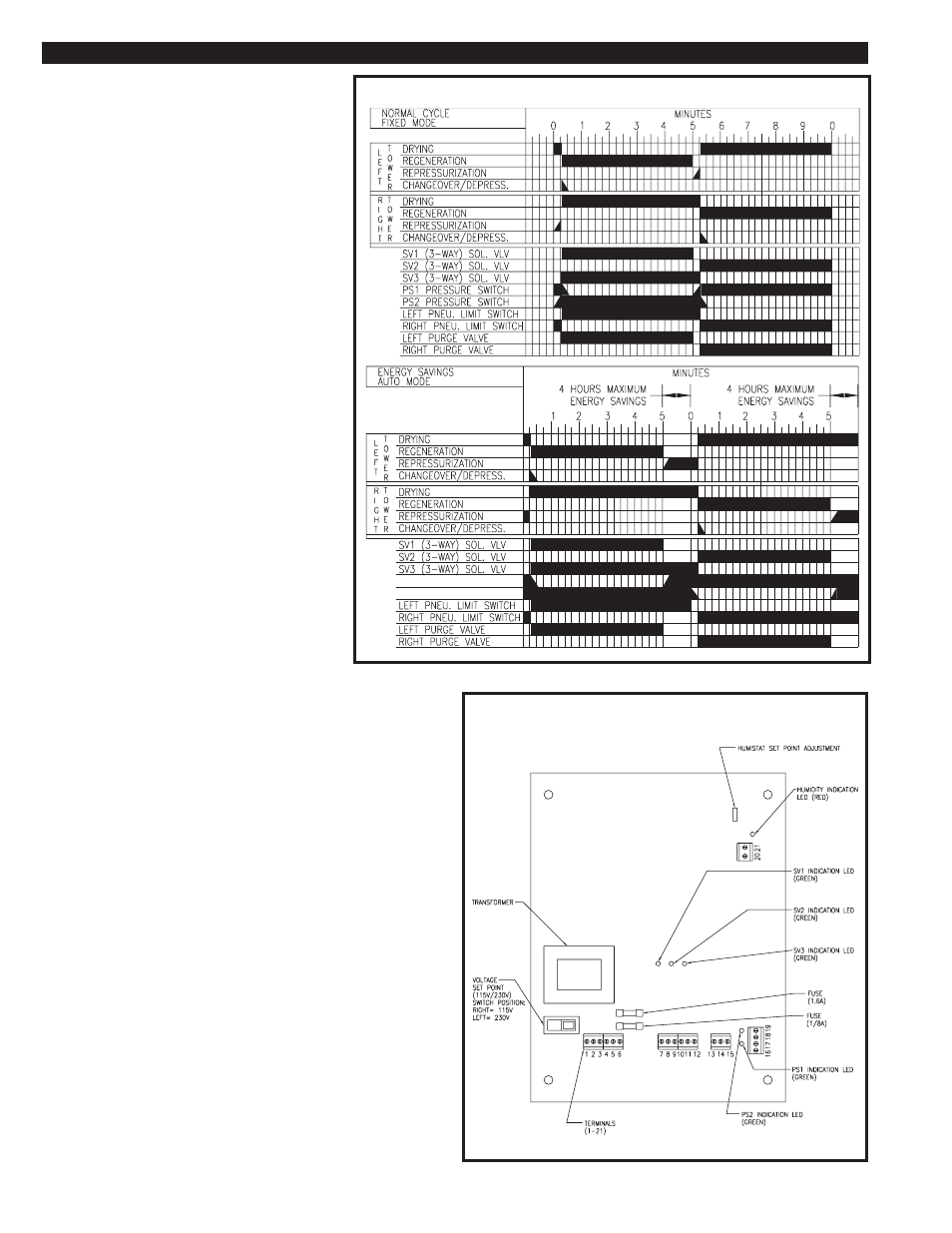

FIGURE 8B TIMING CHART FOR CYCLE SAVER

8.3 FAILURE TO SWITCH ALARM

The FAILURE TO SWITCH ALARM is operational in

the FIXED and AUTO modes.

The dryer is continuously being monitored for

switching failure. Two pressure switches monitor the

pressure in the desiccant towers. If pressure is

present in the tower that should be in the regenerat-

ing stage, the alarm is activated. The printed circuit

board gives the dryer 90 seconds to depressurize

after tower changeover before the alarm is activated.

If one or both of the pressure switches fail, the

alarm is NOT activated, but the dryer is switched into

a 10 minute fixed cycle.

When the alarm is activated, the FAILURE TO

SWITCH LED is illuminated. The alarm does not

stop the dryer from cycling. The FAILURE TO

SWITCH ALARM is a latching alarm. Once the

problem causing the switching failure is corrected,

the FAILURE TO SWITCH RESET PUSHBUTTON

must be pressed to reset the alarm. If the alarm is

reset and the problem is not corrected, the alarm will

be re-activated after 90 seconds.

The switching failure alarm will activate when:

• The inlet transfer valve does not change

positions and does not direct the process flow

through the proper tower.

• The purge exhaust valve does not open on the

regenerating tower or if tower pressure in the

regenerating tower does not drop below 40 psig.

• The purge exhaust valve does not close on the

regenerating tower to allow repressurization.

The GENERAL ALARM contact is closed when this

alarm is activated.

8.4 GENERAL ALARM

The general alarm contact was provided for the customer to wire the

dryer’s alarm into a main control room, or to a warning light or horn.

The contact is a normally open dry contact. The contact is closed if

the SWITCHING FAILURE ALARM has been activated. The contact

will only reset if the alarm condition is corrected.

FIGURE 8C CYCLE SAVER PRINTED CIRCUIT BOARD

8.5 PRINTED CIRCUIT BOARD (LEDs)

The Humidity Indication LED (RED) is on when the humidity is above

the set point.

The SV1 Indication LED (GREEN) is on when the valve is energized.

The SV2 Indication LED (GREEN) is on when the valve is energized.

The SV3 Indication LED (GREEN) is on when the valve is energized

The PS1 Indication LED (GREEN) is on when the switch is closed.

The PS2 Indication LED (GREEN) is on when the switch is closed.

Note: These LEDs are located on the inside of the control box on

the printed circuit board. Figure 8C illustrates the LEDs loca-

tions.

LEFT TOWER PRESSURE (PS1)

RIGHT TOWER PRESSURE (PS2)