Section 3 - specifications – Van Air Systems FR-1600 User Manual

Page 3

PAGE 3

3.1 SPECIFICATIONS

WEIGHT .............3625 Lbs (without desiccant installed)

5485 Lbs (with desiccant installed)

DIMENSIONS ..................... See SECTIONS 3.2

IN/OUT CONNECTION....... 3" 150# RF FLANGE

VESSELS (desiccant towers)

Construction ................... Manufactured to the ASME CODE, Section VIII, Division 1.

Vessels stamped "U" symbol.

Design Pressure ............. 175 PSIG

Design Temperature ....... -20

O

F TO 300

O

F

PIPING

Threaded fittings: ........... ASME B16.3

Threaded unions: .......... ASME B16.39

Flanges: ......................... ASME B16.5

Welded Fittings ............... ASME B16.9

Pipe: .............................. Carbon steel, Schedule 40

VALVES

Inlet ............................... Proprietary 3-way piloted shuttle valve

Outlet .............................. Two (2) Check valves, wafer type

Purge .............................. Two (2) Butterfly valves with spring return actuators (air to open - fail closed)

CONTROL AIR FILTER

Construction ................... Aluminum housing

SEPARATOR/PREFILTER, PREFILTER, AFTERFILTER

Construction ................... Aluminum housing

PRE-COOLER

Core. ...............................Aluminum

Fan..................................Polypropylene blades with Aluminum hub

Fan Guard ......................Steel

ELECTRICAL

Standard 115 Volt ........... 115-120V/1PH/50-60Hz

DESICCANT

Material ........................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower ....... 930 Lbs.

OPERATING CONDITIONS

Inlet Air Pressure ............................ MIN 80 PSIG ...........MAX 175 PSIG

Inlet Air Temperature ...................... MIN 40°F.................MAX 150

O

F

Ambient Air Temperature................ MIN 40

O

F ................MAX 120

O

F

SYSTEM RATED INLET CONDITIONS

Inlet Air Pressure ............................ 100 PSIG

Inlet Air Temperature ...................... 150

O

F (based on 85°F ambient and 15°F approach from the pre-cooler)

Relative Humidity (saturation) ........ 100% RH

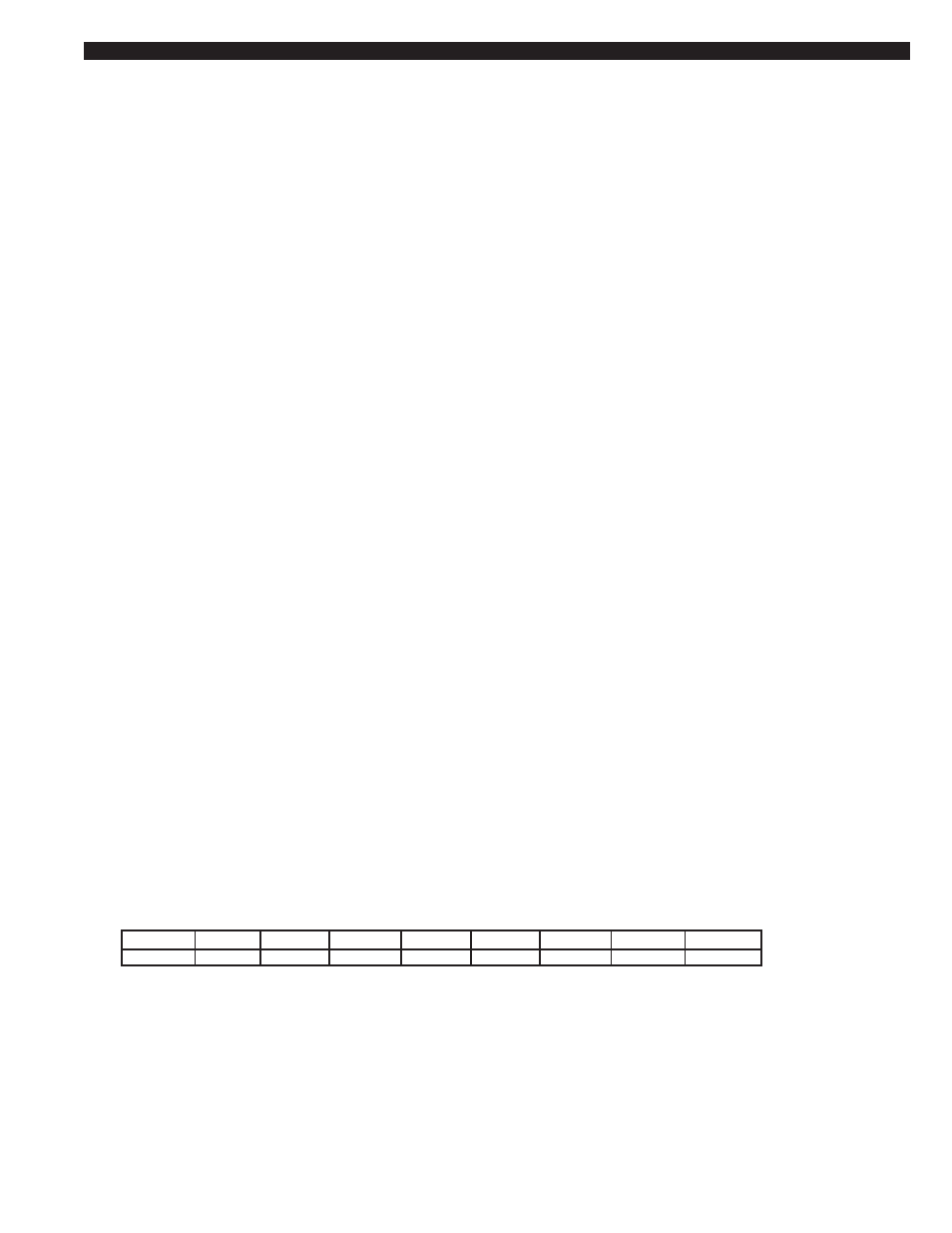

DRYER FLOW CAPACITIES (SCFM) at various pressures (100

0

F)

80 PSIG 100 PSIG 110 PSIG 125 PSIG 140 PSIG 150 PSIG 160 PSIG

175 PSIG

FR-1600

1321 1600 1668 1766 1858 1917 1975 2058

SPECIFICATIONS

SECTION 3