Van Air Systems FR-1600 User Manual

Page 14

PAGE 14

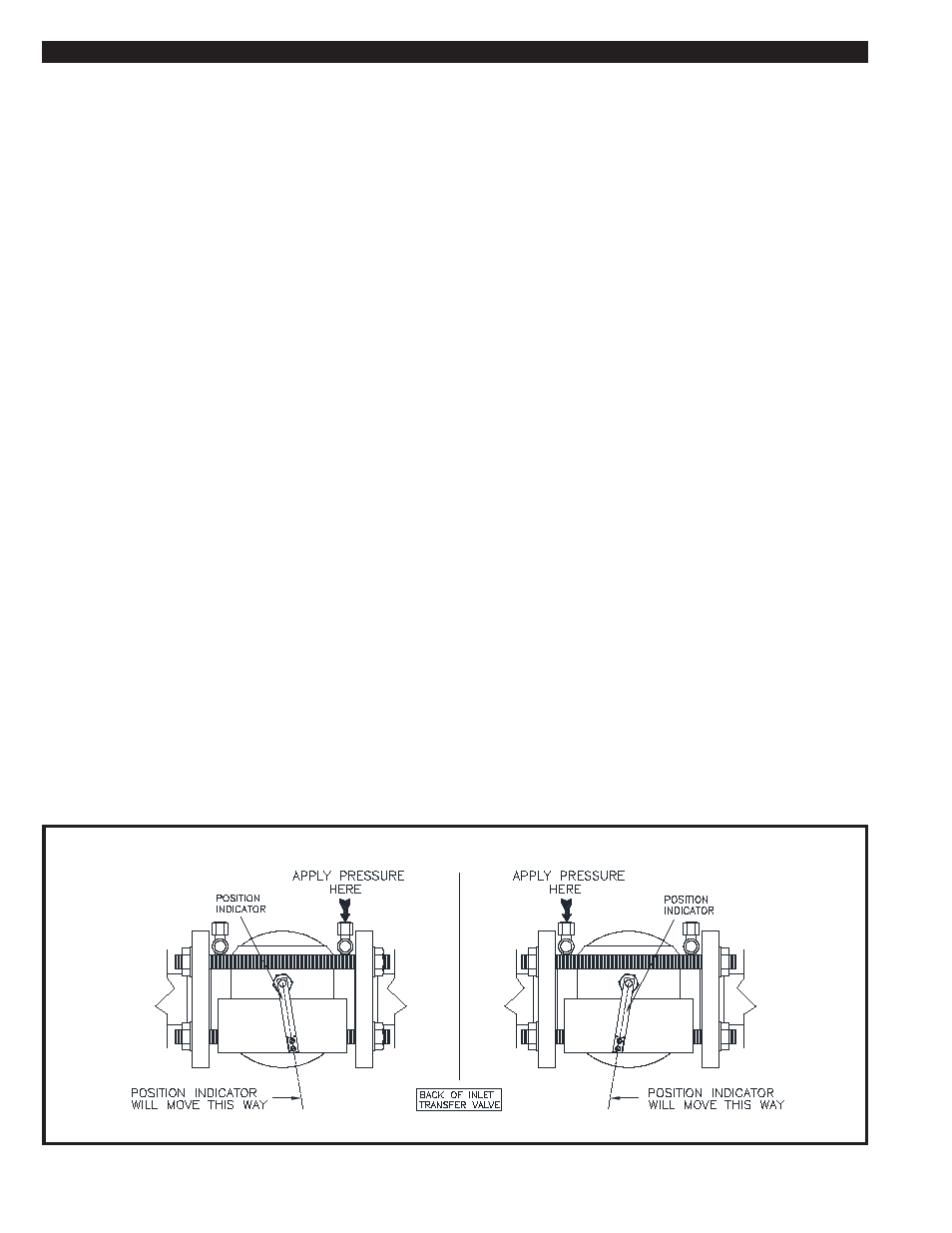

10.4 CHECKING THE INLET TRANSFER VALVE

The inlet transfer valve should not change position until both towers

are at equal pressure. At tower changeover, the regenerating tower

should approach full line pressure before the inlet valve will switch.

Make sure that there are no leaks in the piping or fittings. Make

sure that the purge exhaust valves are closing and that the purge

metering valve is properly set.

The exhaust ports on top of the pilot valves (SV1 & SV2) should not

have air exhausting through them continuously. If air is exhausting

continuously through either of the exhaust ports, the inlet transfer

valve or exhaust valves are faulty and should be rebuilt or replaced.

To test the inlet transfer valve for proper operation, turn off the

power, isolate and depressurize the dryer.

Remove the two pilot lines to the inlet valve. The pilot lines are

connected to the outside flanges of the valve. Reference

FIGURE

10C. Using an air nozzle and clean air, pressurize one of the ports.

Observe the position indicator. It should move in the direction of

the port that is being pressurized. No air should be exhausting from

the other port. Pressurize the other port. The valve should move to

the other side. If the valve does not move or air is being exhausted

out of the port that is not pressurized, the inlet transfer valve must

be rebuilt or replaced. Reference

SECTION 11.3 for repair kit part

numbers.

10.5 CHECKING THE PURGE EXHAUST VALVES

The purge exhaust valves are normally closed. They can be

checked by removing the pilot air lines to them. The valves should

be closed.

Using an air nozzle and clean air, pressurize the purge exhaust

valves. The valves should open when pressurized. If valve does

not open and close, it should be rebuilt or replaced. See

SECTION

11.3 for repair kit part number.

10.6 CHECKING THE OUTLET CHECK VALVES

This dryer system uses two check valves for outlet air control. If

either of the outlet valves fails, one of the following will occur:

• A large amount of air will purge from one tower

• The outlet air flow will be blocked

If either happens, the faulty check valve must be replaced. See

SECTION 11.3 for part number.

TROUBLESHOOTING

SECTION 10

FIGURE 10C INLET TRANSFER VALVE DETAIL