Specifications – Van Air Systems HL-200 - HL2000 User Manual

Page 3

PAGE 3

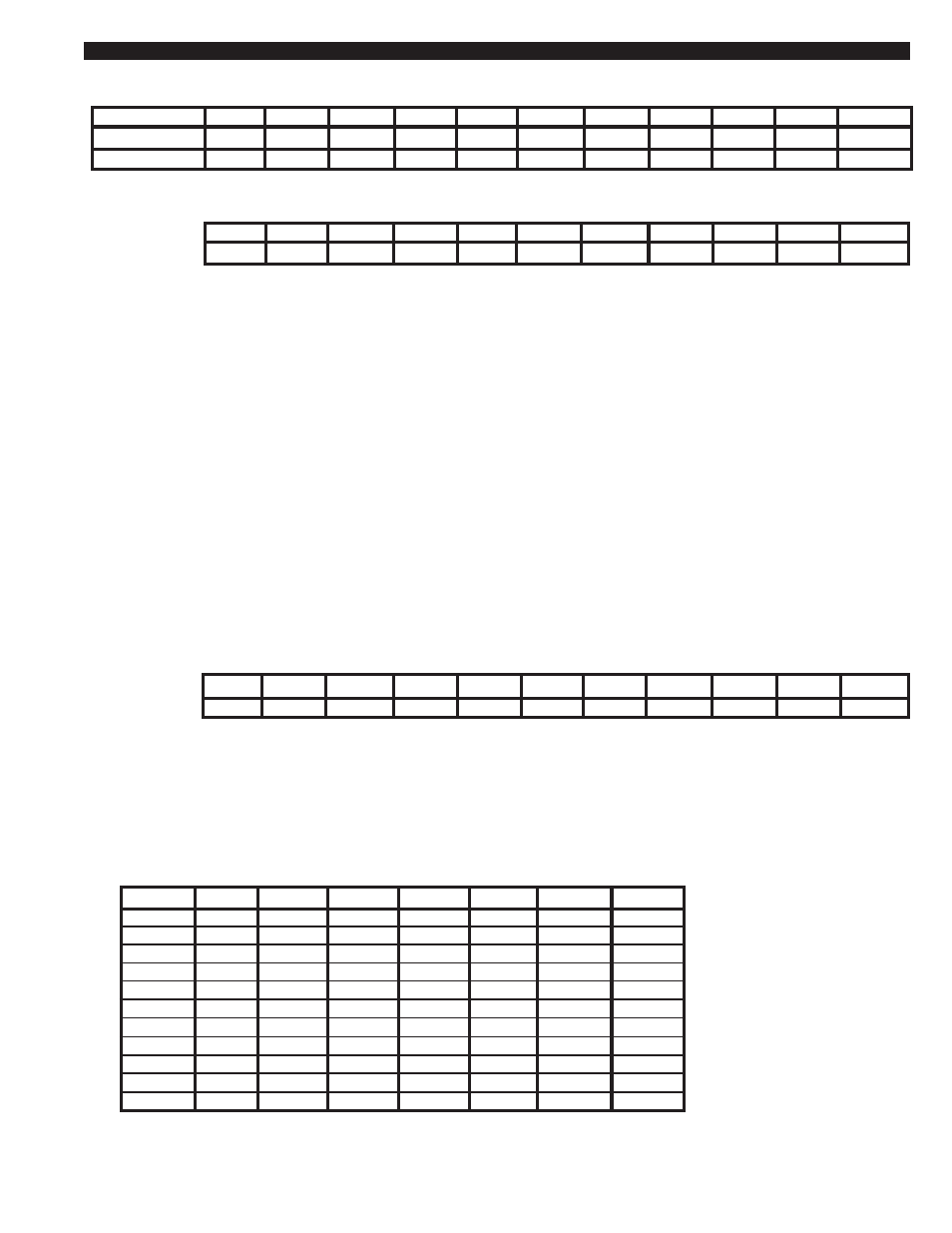

DIMENSIONS AND SPECIFICATIONS

SECTION 3

3.1 DRYER SPECIFICATIONS

WEIGHT (with desiccant installed)

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

HL-1000

HL-1250

HL-1500

HL-1750

HL-2000

N4 STANDARD

660 lbs

715 lbs

1035 lbs

1160 lbs

1680 lbs

1830 lbs

2635 lbs

2885 lbs

3870 lbs

4095 lbs

4370 lbs

ALL OTHERS

700 lbs

755 lbs

1075 lbs

1200 lbs

1720 lbs

1870 lbs

2675 lbs

2925 lbs

3910 lbs

4135 lbs

4410 lbs

DIMENSIONS

.............. See SECTIONS 3.2 through 3.4

IN/OUT CONNECTION

All models have 150# ANSI RF flanged inlet and outlet connections. Bolt holes straddle centerlines.

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

HL-1000

HL-1250

HL-1500

HL-1750

HL-2000

1-1/2"

1-1/2"

1-1/2"

1-1/2"

2-1/2"

2-1/2"

2-1/2'

2-1/2"

3"

3"

3"

VESSELS (desiccant towers)

Construction .................. Manufactured to the ASME CODE, Section VIII, Division 1.

Models HL-200 through HL-250 vessels stamped "UM" symbol. Models HL-375 and larger vessels stamped "U" symbol.

Design Pressure ............ 150 PSIG

Design Temperature ...... -20

O

F TO 300

O

F

PIPING

Threaded fittings: .......... ANSI B16.3

Threaded unions: .......... ANSI B16.39

Flanges: ......................... ANSI B16.5

Pipe: ............................... Carbon steel, Schedule 40

VALVES

Inlet ............................... Proprietary 3-Way piloted shuttle valve

Outlet ............................. Two (2) Check valves, butterfly type

Purge ............................. Normally closed, diaphragm type

CONTROL AIR FILTER

Construction .................. Zinc housing

ELECTRICAL

Standard 115 Volt .......... 115-120V/1PH/50-60Hz

Optional 230 Volt: .......... Main power: 220-240V/1PH/50-60Hz

Control power: Transformed to 115-120V/1PH/50-60Hz, on Emcon II units only

DESICCANT

Material .......................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower (LBS)

HL-200

HL-250

HL-375

HL-500

HL-650

HL-800

HL-1000

HL-1250

HL-1500 HL-1750

HL-2000

106

130

203

266

366

440

560

678

872

986

1119

OPERATING CONDITIONS

Inlet Air Pressure ............................ MIN 60 PSIG ......... MAX 150 PSIG

Inlet Air Temperature ..................... MIN 40

O

F ............... MAX 120

O

F

Ambient Air Temperature ............... MIN 40

O

F ............... MAX 120

O

F

RATED INLET CONDITIONS

Inlet Air Pressure ............................ 100 PSIG

Inlet Air Temperature ..................... 100

O

F

Relative Humidity (saturation) ........ 100% RH

FLOW CAPACITIES (SCFM) at various pressures (100

0

F)

60 PSIG

80 PSIG

100 PSIG

110 PSIG

125 PSIG

140 PSIG

150 PSIG

HL-200

130

165

200

209

221

232

240

HL-250

163

206

250

261

276

290

300

HL-375

244

310

375

391

414

436

449

HL-500

326

413

500

521

552

581

599

HL-650

423

537

650

678

717

755

779

HL-800

521

661

800

834

883

929

959

HL-1000

651

826

1000

1043

1104

1161

1198

HL-1250

814

1032

1250

1303

1380

1452

1498

HL-1500

977

1238

1500

1564

1655

1742

1797

HL-1750

1140

1445

1750

1825

1931

2032

2097

HL-2000

1303

1651

2000

2085

2207

2323

2397