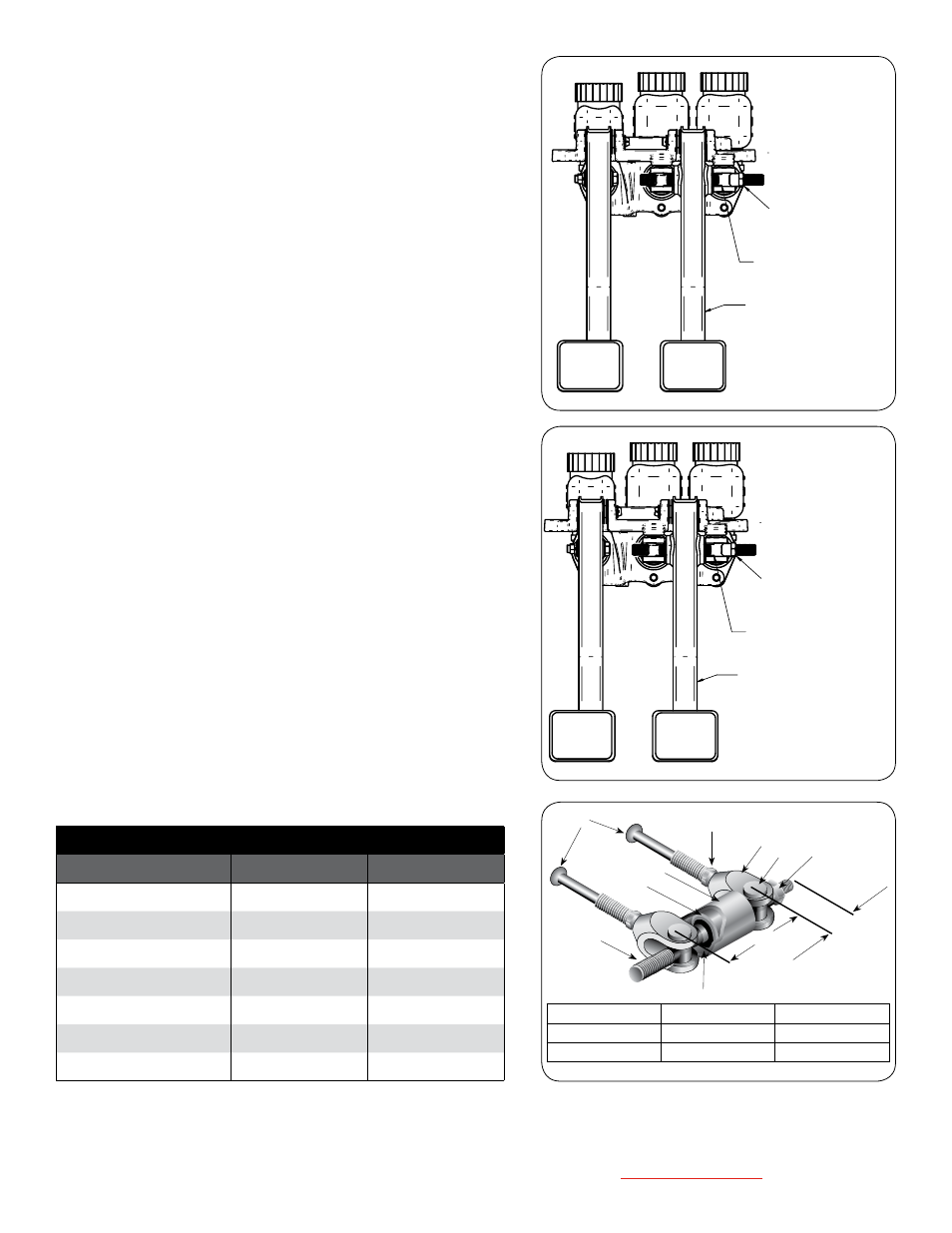

F. balance bar adjustment and operation, Diagram 9 diagram 10, Diagram 8 diagram 7 – Tilton Firewall – Aluminum & Steel (98-1203) User Manual

Page 4: Force distribution

F. Balance Bar aDjustMent anD operation

When running on pavement, you want the front tires to lock-up with slightly less

pedal pressure than the rear tires. This will help to keep the car stable and prevent it

from going into a spin.

1. Loosen the jam-nut on the adjusting shaft (Item 3 in Diagram 10).

A jam-nut is not used with a remote adjuster.

2. Turn the adjusting shaft (Item 8 in Diagram 10) by hand or with the remote cable

adjuster so that it advances the spherical bearing closer to the selected master

cylinder, increasing the braking force produced by that master cylinder (Chart 2).

The balance bar must be adjusted with the pedal in the relaxed position (Diagram

D). It will not rotate while depressing the pedal.

3. The balance bar has a fairly large adjustment range. However, if you find that

what you need is outside of the adjustment range, you will need to make a master

cylinder bore size change. There are three possible changes that can be made

(See below). All three will allow the spherical joint to move back towards the

center position.

a) Decrease the bore size of the master cylinder closest to the spherical joint

by 1/8". This will decrease the amount of pedal force required from the foot

and increase the amount of pedal travel.

b) Increase the bore size of the master cylinder farthest from the spherical

joint by 1/8". This will increase the amount of pedal force required by the

foot and decrease the amount of pedal travel.

c) Increase the bore size of the master cylinder farthest from the spherical

joint by 1/16". Decrease the other master cylinder bore size by 1/16".

This will maintain the amount of force and pedal travel while making a

relatively large change to the front/rear brake bias.

4. Whenever making an adjustment, remember to tighten the jam-nut (Item 3 in

Diagram 10) afterwards. A jam-nut is not required when a Remote Brake Bias

Adjuster is used.

Center

7

Adjustment

9

1

2

3

5

6

8

4

1. Clevis

4. Retaining Ring Clips 7. Pushrod

2. Barrel Nuts

5. Pivot Sleeve

8. Adjusting Shaft

3. Jam-nuts

6. Spherical Bearing

9. Jam-nuts (Pushrod)

Diagram 9

Diagram 10

STIFF, LIGHTWEIGHT

TUBULAR STEEL

CLUTCH AND BRAKE

PEDALS

JAM NUT SECURES BIAS BAR SETTING.

FOR REMOTE CABLE ADJUSTER, REMOVE

JAM NUT AND SECURE CABLE TO END OF

BIAS BAR WITH CABLE COUPLER

CLEVIS DESIGNED FOR

MINIMUM FREE PLAY WITH

OR WITHOUT JAM NUTS

STIFF, LIGHTWEIGHT

TUBULAR STEEL

CLUTCH AND BRAKE

PEDALS

JAM NUT SECURES BIAS BAR SETTING.

FOR REMOTE CABLE ADJUSTER, REMOVE

JAM NUT AND SECURE CABLE TO END OF

BIAS BAR WITH CABLE COUPLER

CLEVIS DESIGNED FOR

MINIMUM FREE PLAY WITH

OR WITHOUT JAM NUTS

Diagram 8

Diagram 7

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Force Distribution

(2.62" Clevis Center-to-Center)

Spherical Joint Position

Left Clevis

Right Clevis

3/8" left-of-center

64.3%

35.7%

1/4" left-of-center

59.5%

40.5%

1/8" left-of-center

54.8%

45.2%

Centered

50.0%

50.0%

1/8" right-of-center

45.2%

54.8%

1/4" right-of-center

40.5%

59.5%

3/8" right-of-center

35.7%

64.3%