Tilton 6-rivet Metallic Discs (98-1340) User Manual

Installation instructions, Metallic racing clutch discs (6-rivet hubs)

InstallatIon

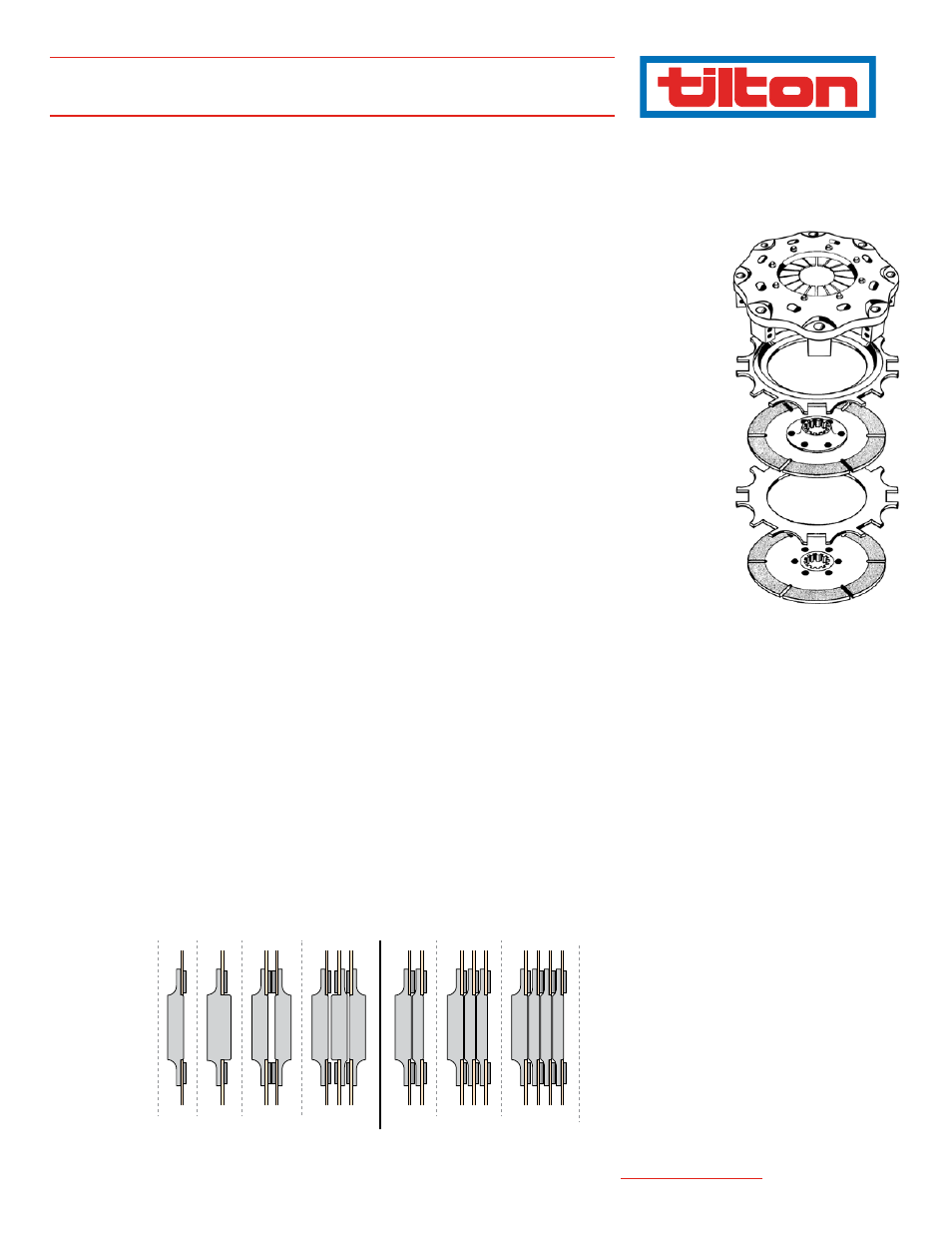

Install the plates and discs into the clutch (Diagram A) in the following manner:

Make sure to check the following:

Metallic Racing Clutch Discs (6-Rivet hubs)

INSTALLATION INSTRUCTIONS

98

-13

40

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Diagram A

MaIntenance

DIscs

Clutch discs start new at .104" thick. These should be replaced when the total pack wears .030". This means the individual disc thickness should not be less

than: Single disc = .074"

|

Two disc = .089"

|

Triple disc = .094"

|

Four disc = .097"

Note:

The friction material used on these discs is wear resistant. It will typically wear quickly for the first .002" of disc thickness, and

then wear much slower after that.

Pressure Plate anD Floaters

Check the plates periodically for warping. This warping is caused by heat put into the clutch from slipping. Check warping with a straightedge and feeler

gauges. Maximum allowable warping is .008" in any plate. Pressure plates can be resurfaced to a minimum thickness of .525" (after surfacing). Floater plates

should never be resurfaced. Be sure to align the balance marks when reinstalling the plates.

CAUTION:

Never put new discs into a clutch that has a warped pressure plate or floater plates. There will not be full contact across

the face of the discs and they will wear out quickly. On the same note, discs that were used in a clutch with a warped pressure plate or

floater plates should never be used in a new clutch assembly.

• Hubs make full spline contact with

input shaft

• There is clearance between hubs

(and rivets)

• There is clearance between the

bottom disc and flywheel bolts

Note:

Friction pads should be stacked over each other as shown in Diagram A and not staggered.

Back-to-Back DIsc Packs

Contains “A”, “F”, “AA” or “ABA” in the part #.

1. Install pressure plate with raised ring against diaphragm.

2. Install disc #1 (A or F hub) with TE logo on rivet heads

towards the flywheel.

3. Install floater plate (two or three disc only).

4. Install disc #2 (A or B hub) with TE logo on rivet heads

away from the flywheel.

5. Install floater plate (three disc only).

6. Install disc #3 (A hub) with TE logo on rivet heads

away from the flywheel.

stackeD DIsc Packs

Contains “AC”, “ACC” or “ACCC” in the part #.

1. Install pressure plate with raised ring against diaphragm.

2. Install disc #1 (A hub) with TE logo on rivet heads towards

the flywheel.

3. Install floater plate (two, three or four disc only).

4. Install disc #2 (C hub) with TE logo on rivet heads towards

the flywheel.

5. Install floater plate (three or four disc only).

6. Install disc #3 (C hub) with TE logo on rivet heads towards

the flywheel.

7. Install floater plate (four disc only).

8. Install disc #4 (C hub) with TE logo on rivet heads to-

wards the flywheel.

A = Solid, 6 rivet, outer (.375" thick)

B = Solid, 6 rivet, inner (.375" thick)

C = Solid, 6 rivet, thin inner (.250" thick)

F = Solid, 6 rivet, outer (.550" thick)

C

C

A

C

C

A

C

C

A

A

A

B

A

A

A

F

Back Bo Back

Stacked

FL

Y

W

H

EEL

CL

U

TCH

C

O

V

ER