Tilton Firewall – Aluminum & Steel (98-1203) User Manual

Page 2

installation

1. Set the clevis center-to center distance at 2.620 +/- .040". You need to do

this before attaching the master cylinders.

2. Thread the adjusting shaft left or right until the spherical bearing is near

the center of the pivot sleeve. Note that the right end of the balance bar

has a longer threaded section and will stick out farther.

3. If you are using a remote adjuster, remove the jam-nut from the adjusting

shaft. If you are not using a remote adjuster, tighten the jam-nut against

the barrel nut on the longer end (right end) of the shaft. The round end

goes against the barrel nut.

4. Mount the pedal assembly in the car. It is important to mount the frame

rigidly so that it does not move when heavy pedal force is applied to both

pedals. See diagrams 5–8 for mounting hole locations. The four large

through holes are for attaching to the main support structure while the

two tapped holes and the six master cylinder mounting studs (which

often pass through a firewall) can be used for additional stiffening.

5. If you are going to bench bleed your master cylinders, now is the time.

6. Bolt the master cylinders into place with the supplied 5/16"-24 serrated

flange nuts. Make sure the master cylinder pushrod has a jam-nut.

7. Thread the master cylinder pushrods into the clevises equal amounts

(you may need to alter this later) until the pedal foot pad is in the

correct position for the driver (See Diagram 2). A minimum of .25" thread

engagement (6 threads) is recommended.

8. Tighten the master cylinder pushrod jam-nuts against the clevises.

9. Make sure that the chosen pedal position allows a full 1" of stroke at both

master cylinders.

10. Make sure that the adjusted position also allows both master cylinders

to return to their fully relaxed position without binding. Preload on the

master cylinder pushrods can cause the brakes to lock up when hot when

there is no force on the pedal.

11. Attach hydraulic lines.

12. Attach the reservoirs and bleed as directed in the master cylinder

directions. With a balance bar, always bleed a front and a rear caliper at

the same time to insure total air removal.

13. Apply the brakes and adjust the pushrod length so the adjusting shaft is

parallel to the master cylinder mounting surface

(See Diagram 3). If one pushrod is shortened by one revolution,

lengthening the other by one revolution will maintain the same pedal

position. Do not extend the pushrods to the point where they preload

the master cylinder pistons. After adjusting, tighten the jam-nuts on both

pushrods.

14. You will need to test drive the vehicle to determine if adjustments need

to be made to the brake bias (front/rear brake force distribution). See

Section F for making bias adjustments.

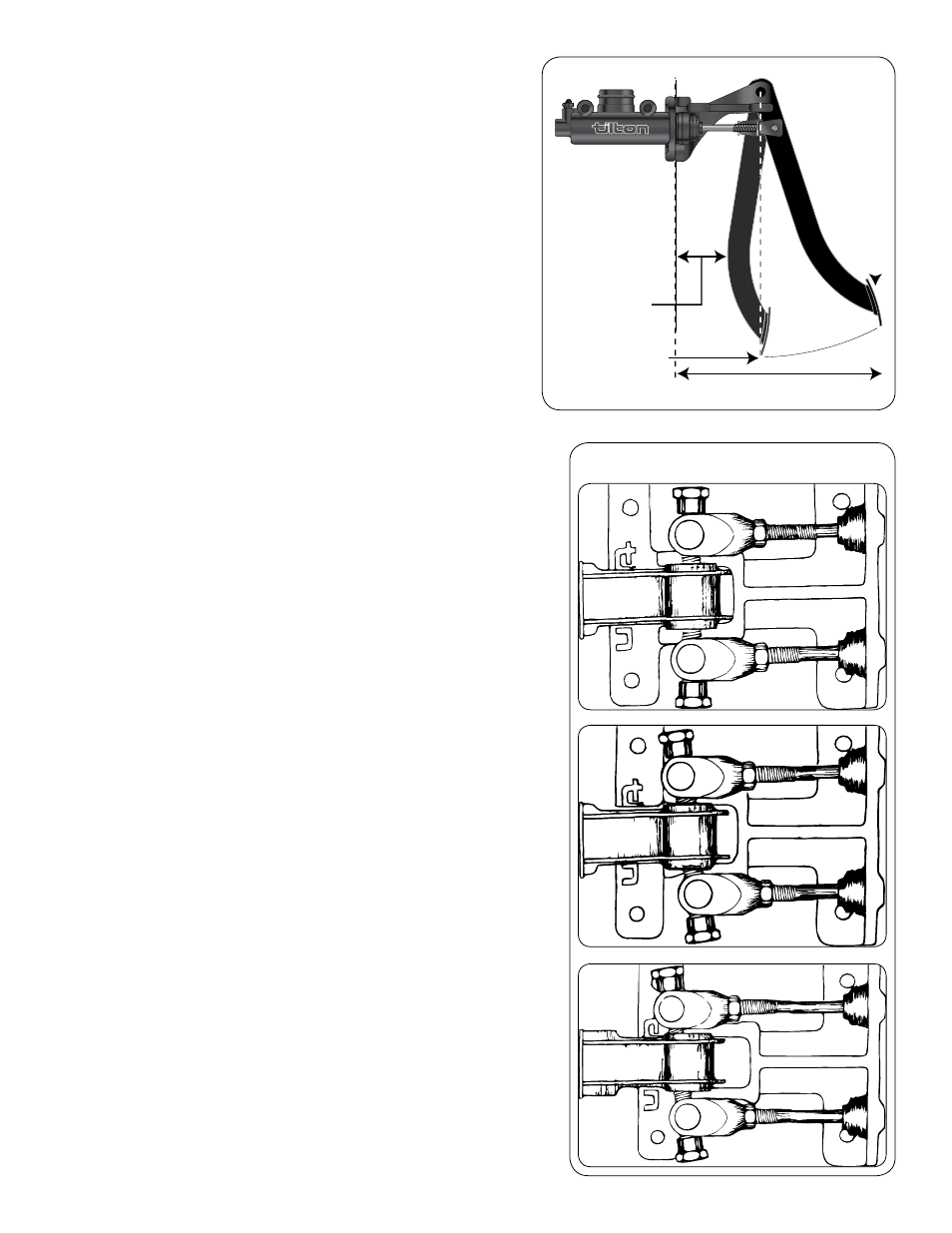

Diagram 3

FIREW

AL

L

GAP REQUIRED

9.5" MINIMUM

PED

AL

AT

REST

MASTER CYLINDER

BOTTOMED

11.75"

Diagram 2

3.1

Pedal De-

pressed

Balance Bar

not at an

angle

(Correct)

3.2

Pedal De-

pressed

Balance Bar

at an angle

(Incorrect)

3.3

Pedal Re-

laxed

Balance Bar

may or may

not be

at an angle