Tilton Standard Oil Cooler Pump (98-1901) User Manual

Installation instructions, Transmission / differential oil cooler pump

How It works

The Tilton Differential Pump is a positive displacement type of pump, so its output is directly proportional

to the motor speed. If a lighter load increases the motor speed by 25%, then the flow rate increases by

25%. The flow rate vs. pressure is shown in Graph 1 with a maximum available pressure of 60 PSI. A fluid

system will only flow as much as the smallest restriction will allow. Larger diameter lines and fittings allow

more flow and place less load on the pump. This pump is self-priming and can be placed up to 8 ft above

the source from which it draws. The typical application for the pump is in a differential or transmission

cooling system. However, the pump can be used for other applications such as emptying fuel tanks. A 12-

volt DC, 10-amp power supply is required. The current draw is 6.6 amps under a maximum load condition

with a more typical current draw between 2 and 3 amps. This pump has a very light weight at 3.5 lbs and

has a flow rate of 1-2 gallons per minute. There are two types of diaphragms available for the differential

pumps; the BUNA type diaphragms are for standard coolants and the VITON diaphragms are for the more

corrosive coolants.

InstallatIon notes

The Tilton Differential Pump is placed inline with the cooling system as shown in Diagram 1. Placing the

pump on the outlet side of the cooler exposes it to lower temperatures significantly increasing the life

and reliability of the pump. A 40-mesh (400 micron) strainer or filter placed inline before the inlet of the

pump prevents foreign objects from damaging the pump. Heavy gear oil must be brought up to oper-

ating temperature before the pump is engaged. The cold fluid can be very thick and place an unusually

large strain on the pump. Tilton recommends the use of an on/off switch so the pump can be turned off

during warm-up periods. The pump includes an integral cooling fan to keep the pump cool during loaded

conditions. If the pump is mounted in a vertical position, mount the pump with the motor above the pump

inlet and outlet to prevent damage to the motor in the event of a fluid leak. The pump head can be rotated

in 180-degree increments, allowing a variety of hose positions. Be careful not to damage the plastic pump

housing by over tightening the fittings. If a check valve is placed inline with the pump, the check valve

must have an opening pressure of no more than 2 PSI. The electrical hook-up is simple. Connect the pump

to a 12-volt DC supply with a 10-amp fuse inline with the (red) positive lead. The black lead is the chassis

ground.

PumP removal

1. Drain any excess coolant out of the pump before continuing

2. Disconnect the electrical connections

3. Disconnect the inlet and outlet lines

4. Remove the pump from the vehicle

mountIng Hole DImensIons

• 2.25” vertical centers x 3.25” horizontal centers.

• Drill hole diameter: 3/16”, 4 places.

• Use high quality #10 bolts with lock nuts

PlumbinG

• For best results, use AN8 steel braided flexible hose.

• Use only 3/8” NPT fittings at the pump inlet and outlet.

OPeratiOn

• Allow the pump to prime with the discharge line open to prevent airlock.

• The pump will not be harmed if it is allowed to run dry. It is self-priming.

electrical

• Use a minimum of 16AWG stranded wire for power connections.

• Use a 10-amp inline fuse on the 12-volt DC (red) power connection.

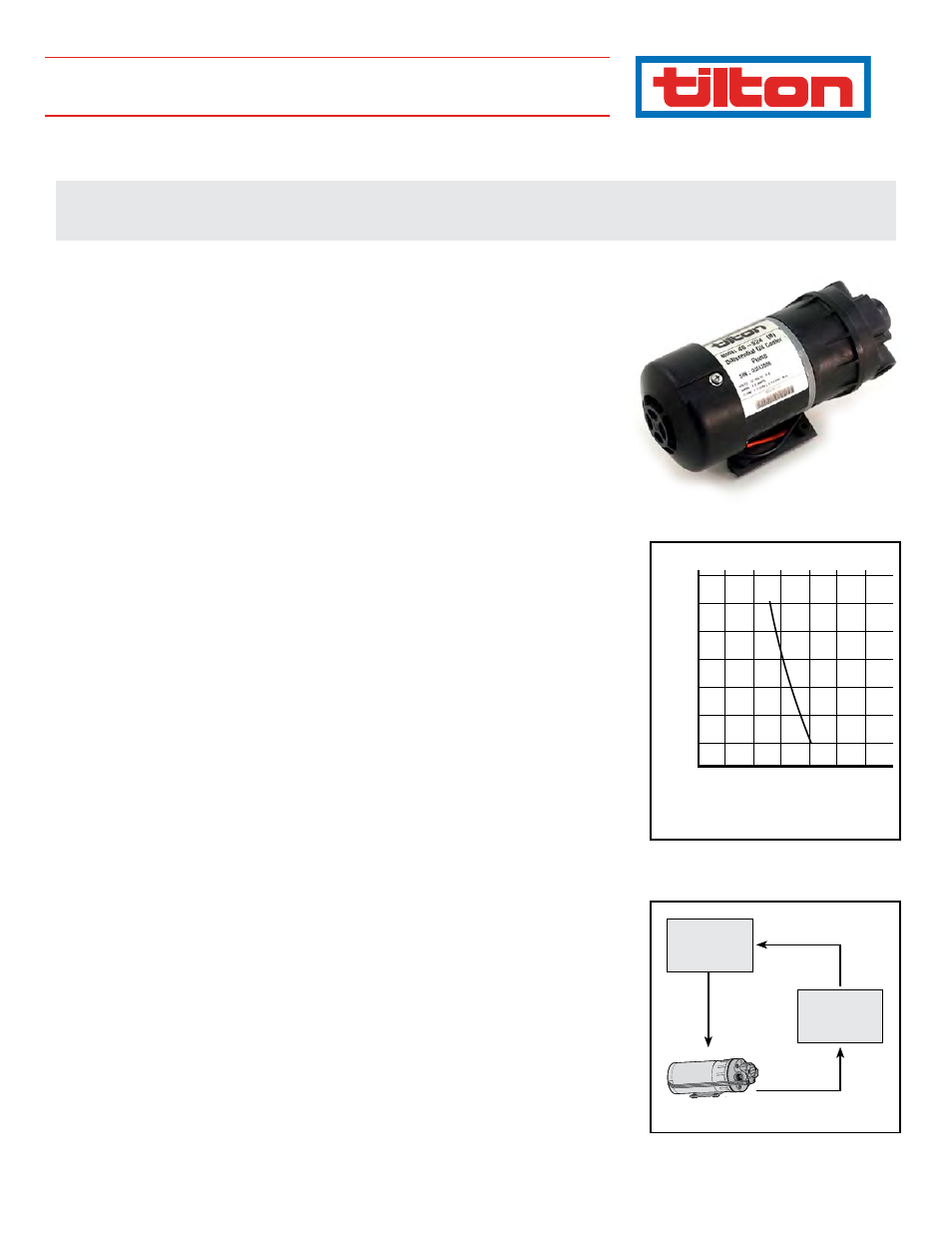

Head-Flow Performance

70

60

50

40

30

20

10

0

.5

0

1.0

1.5

2.0

2.5

3.0

Flow Rate (GPM)

Pr

essur

e (PSI)

Graph 1

Flow: 1-2 GPM (4.6-9.1 LPM) | Pressure: 60 PSI (3.5 BAR) MAX | Voltage: 12 VDC | Current: 8 AMPS

| Temperature range: 40-160˚ F Continous; 265˚ F (MAX) Intermittent | Prime: Self-priming up 8 ft (2.6 meters) vertical height

(40-524 & 40-525)

Transmission / Differential Oil Cooler Pump

INSTALLATION INSTRUCTIONS

98

-19

01

Diff/trans

cooler

Differential

or

transmission

Diagram 1