Water softener trouble shooting, Water was soft but now feels hard, What to check how to correct – Star Water Systems S15DC39DR User Manual

Page 13

13

© Copyright 2011 Star Water Systems. All rights reserved.

STAR WATER SYSTEMS

| 95 North Oak St. | Kendallville, IN 46755 | starwatersystems.com

wATER SOFTENER TROublE ShOOTINg

WATER WAS SOFT BUT NOW FEELS HARD

WHAT TO CHECK

HOW TO CORRECT

No salt in brine tank

Add salt to brine tank and maintain salt level above water level.

Manually initiate the regeneration cycle and allow softener to

totally go through all regeneration cycles.

Electrical service to unit has been interrupted

Make certain that the power cord is plugged into a 115V grounded

outlet that cannot be turned off accidentally by a wall switch or

pull chain. Check for blown fuses. In case of electrical power out-

ages, reset the time of day. Some valves utilize a battery - see

valve instructions for battery replacement.

Has softener valve head been programmed to regener-

ate after installation

See valve programming instructions. Was water properly tested

and diagnosed for correct setting? Have additional people moved

in or water usage increased?

Has the bypass been used and not connected back into

service

Make sure the handle of the bypass valve is in the service posi-

tion. On a 3-way bypass position, open the inlet and outlet valves

ad close the bypass valve.

Salt is bridging in tank

Salt in bottom of tank has hardened and is not allowing water/salt

mixture to get to the bottom of salt and consequently over to min-

eral tank. Do not fill salt tank completely (3/4 full). Use a stick or

broom handle and poke into salt, making sure it is broken up.

Salt tube going from salt tank to mineral tank is plugged

or insufficient water flowing into brine tank

Put unit into “Brine Rinse” position, make sure salt water flows

uninterrupted from salt tank to mineral tank. Clean or replace

brine valve. Clean and unplug necessary line so water flows

uninterrupted.

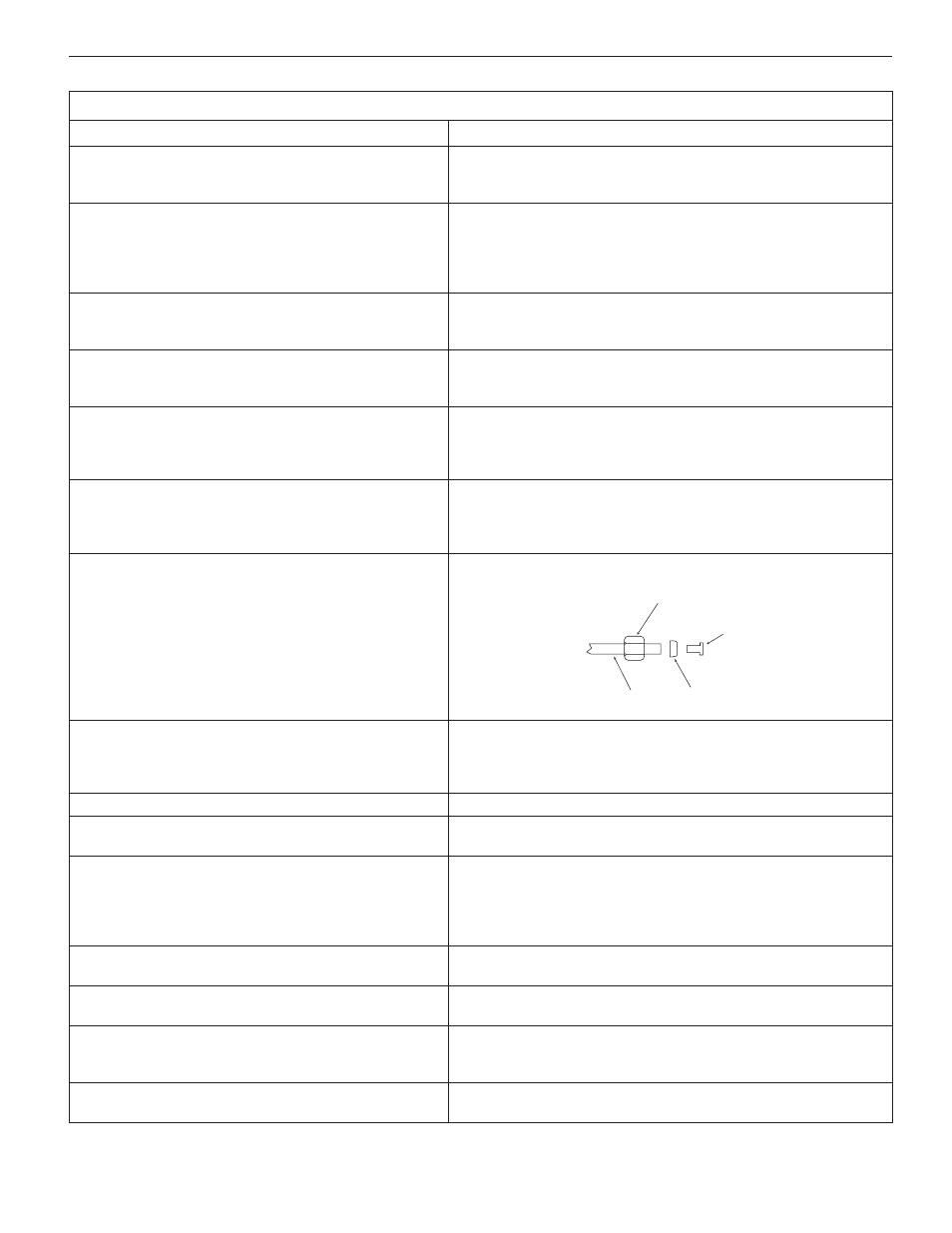

Brine salt line and connections not allowing salt solu-

tion into mineral tank to regenerate

Visually check tubing for cracks or kinks. Check fittings for proper

assembly and tightness as diagrammed.

Brass

Compression

Nut

Brass

Insert

Plastic

Ferrule

Poly

Tubing

IL0707

Injector or injector screen is plugged

Put softener in “Bypass” position and de-pressurize by putting

in “Backwash” position. There are 2 screws on valve neck where

salt line tube enters softener. Remove screws, clean screen and

remove chunks of salt, etc.

Line pressure is too low

Line pressure must be at least 20 PSI at all times.

Is backwash water flowing freely down to drain with an

air gap and no back siphoning

Put valve into “Backwash” position and follow water flow down

to drain.

Too much iron or tannins have fouled the bed

A water softener is only effective for up to limited amounts of iron

and yellowish colored tannins. Draw water before it goes into and

after it flows through softener. Have both samples tested to see

if iron is being removed or if mineral bed is already coated and

fouled.

Salt level setting on valve head is set too low

Verify salt setting and adjust as necessary (consult factory at 1-

800-742-5044)

Valve head or timer is not cycling

Shut off water supply, de-pressurize tank*, unplug unit and

replace valve head motor.

Has softening mineral been exposed to freezing

Freezing weather causes the resin to mush and become ineffec-

tive. Replace resin, properly insulate and shield unit from direct

elements and freezing temperatures.

Leak in distributor tube

Check for cracks in distributor tube. Check o-ring and tube inlet in

bottom of valve. Replace if necessary.