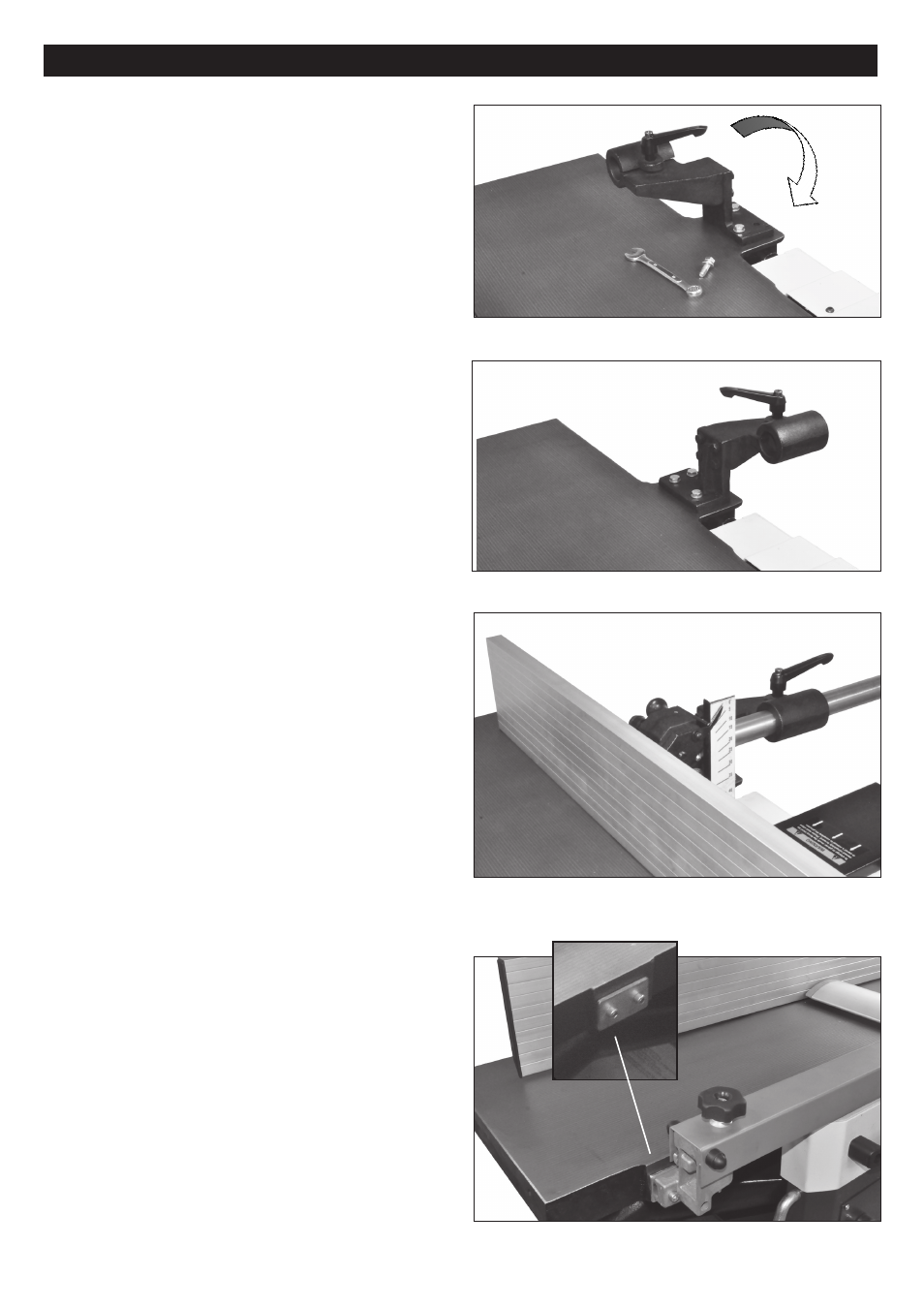

Assembly, Fig. 3 fig. 4 fig. 5 fig. 6 – RIKON Power Tools 25-200H User Manual

Page 9

ASSEMBLY

JOINTER FENCE INSTALLATION

For shipping purposes, the Sliding Fence Bracket (#293)

is installed incorrectly, backwards, extending above the

table surface. FIG. 3, A. This bracket must be reversed

before installing the fence.

WARNING: When working on, or near the machine's bed,

avoid the risk of personal injury by cuts that may result

from touching the knife inserts' sharp edges!

1. Remove the Hex Bolts (#294) that attach the bracket

to the table casting, and turn the bracket around 180

degrees. See FIG. 4 for the correct position for the

bracket.

2. Attach the bracket in place with the three hex bolts and

washers.

3. Locate the Locking Handle and Washer (#292, 246)

from the loose parts bag, and install the handle onto the

sliding fence bracket as shown in FIG. 4, B.

4. The Jointer Fence has been pre-assembled for

shipping. Slide the fence Guide Rail (#300) into the fence

bracket through the hole, and lock it in place with the

handle. FIG. 5.

The Fence Assembly includes a 6" x 43" extruded

aluminum fence, angle adjustment mechanism, angle

scale, and safety cutterhead guard. See page 10

for

information on adjusting the fence for jointing.

FIG. 3

FIG. 4

FIG. 5

FIG. 6

INSTALLING THE CUTTERHEAD GUARD

The cutterhead guard is shipped in two parts; the arm and

bracket Assembly (#360, 364) and Guard (#371). When

assembled and installed, it can be adjusted to provide

maximum protection to the user from the sharp cutterhead

insert knives. Always operate the machine with the guard

properly adjusted for the width and thickness of your stock

being jointed. Keep the guard covering the full cutterhead

when the machine is nt in use to avoid any accidents.

WARNING: When working on, or near the machine's bed,

avoid the risk of personal injury by cuts that may result

from touching the knife inserts' sharp edges!

1. Remove the two Hex Socket Screws (#132) that are

pre-installed on the front side of the outfeed table. FIG. 6.

2. Install the bracket on the end of the Cutterhead Guard

Assembly using the two of hex socket screws. Make sure

the Square Washer/plate (#384)

stays between the table

and cutterhead guard bracket.

3. Insert the curved Cutterhead Guard (#371) through

the front of the guard assembly. The guard will slide back

and forth to cover the cutterhead, and can be secured in

position with the top knob.

9

A

B