Adjustments – RIKON Power Tools 25-200H User Manual

Page 13

13

ADJUSTMENTS

Table Alignment continued from page 12

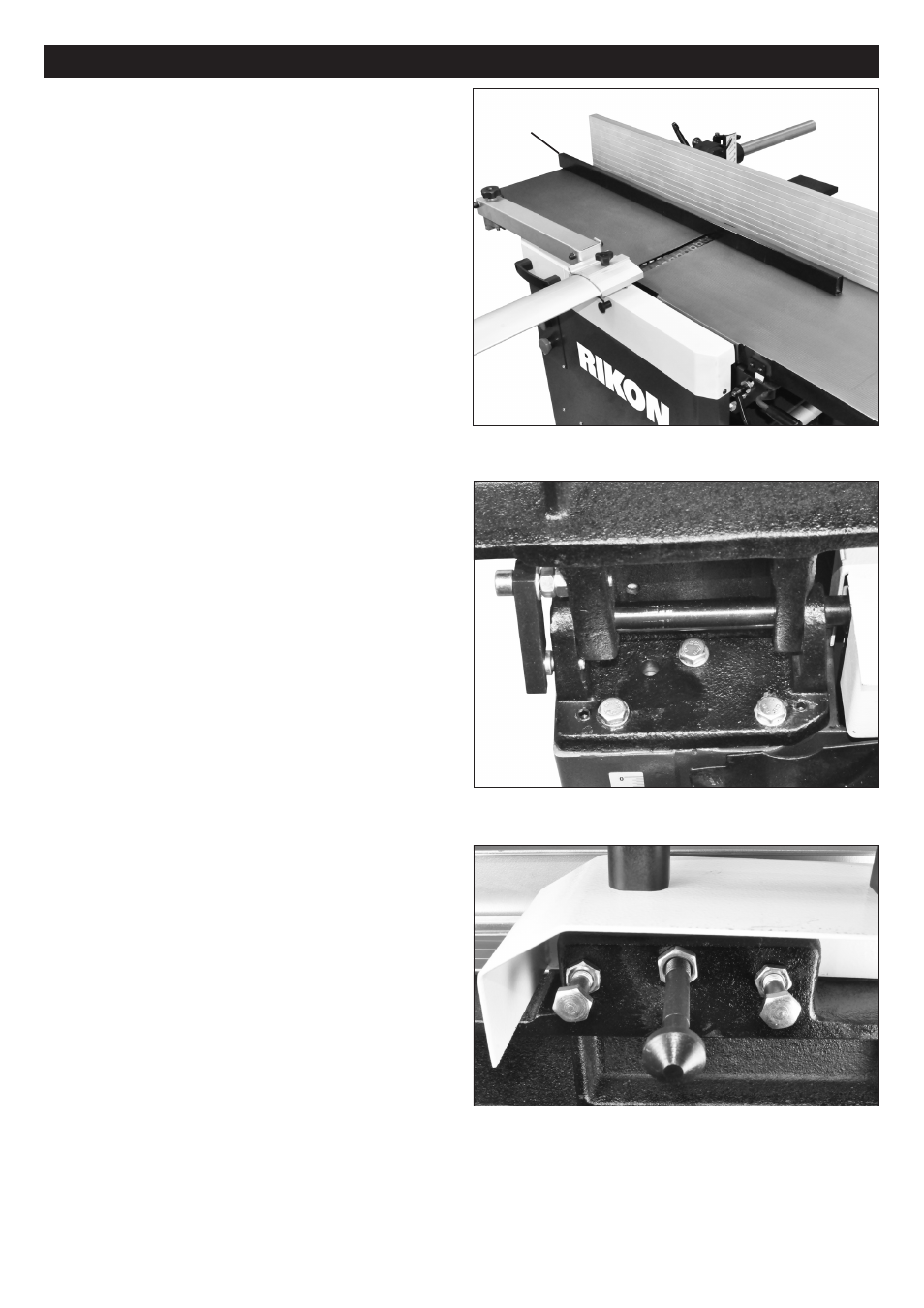

FIG. 18

FIG. 19

FIG. 20

NOTE: It may be easier to remove the fence assembly and

guard for this exercise.

3. Rotate the cutterhead so that the knife inserts do not

interfere with the measurements that will be taken.

4. With a long metal straight edge, place it length-wise

along the outfeed table so that it extends onto the infeed

table. The straight edge should lie level across BOTH

tables. If it does, the tables are true to each other, and the

machine guards can be re-set for use. FIG. 18.

If the straight edge does not lie flat across both tables, then

the tables must be adjusted. Tune the outfeed table, as the

infeed table was factory set to the cutterhead.

ADJUSTING THE OUTFEED TABLE

1. The outfeed table needs to be lifted up and back into

a verticle position. See page 19, step 1 & 2 for full details

on this process. The Dust Chute (#30) should be left in the

down, jointer-use position so adjustments can be made.

2. With the table up, the Mounting Base (#151) for the

out-feed table is exposed. The base has three Hex Bolts

(#154) and four Set Screws (#152) that fasten the table to

the cabinet. The set screws can be adjusted to slightly tilt

the table to align it with the infeed table. FIG. 19.

3. Slightly loosen the three hex bolts so that the set

screws can be adjusted. With small 1/8 or 1/4 turns of the

set screws, tilt the table as needed. A clockwise turn will

advance the set screw, a counter-clockwise turn will retract

them from the base casting.

- The pair of 2 set screws to the far left will raise the left

end of the table. FIG. 19, A & B.

- The pair of 2 set screws to the far right will raise the

forward edge of the table, nearest the cutterhead. C & D.

- The pair of screws furthest back in the base will tilt the

back of the table upward. B & C.

- The pair of 2 set screws at the front of the base will

lift up the front edge of the table. A & D.

- The table can also be tilted down, or up, towards a

specific corner should the situation arise. Three of the set

screws would be adjusted for this. Example: To tilt the far

left corner of the table up, set screws D, then A & C would

be turned. Screw B would be the 'pivot point'

4. The table can also be tilted forward or back with the two

Special Bolts (#142, FIG. 20, E & F). The combination of

the six bolts and screws (A-F) provide a great range of

table positioning to level it with the infeed table.

5. Once adjustments are made, the outfeed table should

be lowered and the flatness measurement taken again with

the straight edge.This may require a few attempts to get

the tables in alignment. Then the three hex bolts (#154)

can be tightened to lock the settings. The two Special Bolts

(E & F) should also be checked to make sure that they

both lie on the Cabinet, then tightened.

6. With the table lowered, make sure the safety Table Lock

(#146) will engage. This special bolt can be adjusted up or

down by its threaded end, then set with the nut . FIG 20, G.

7. Re-adjust, or install the fence and guard for use.

STRAIGHT

EDGE

E

F

A

B

C

D

G