Adjustments – RIKON Power Tools 25-200H User Manual

Page 17

17

ADJUSTMENTS

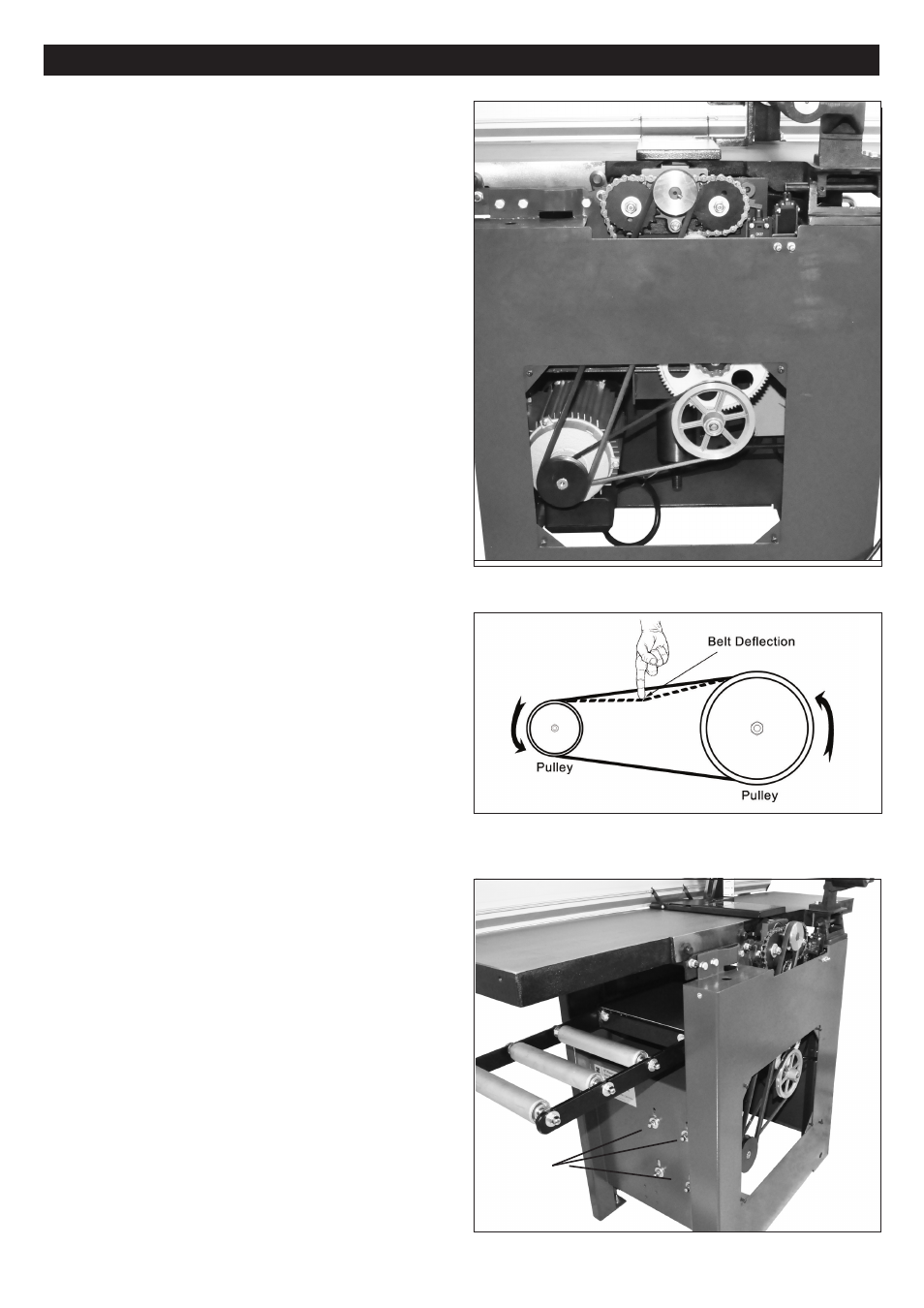

To inspect, adjust or change the drive belts:

1. Make sure that the planer/jointer's switch is turned off,

and the plug is disconnected from the power source.

2. Pull the fence forward, and remove the side panel and

belt cover to expose the motor, pulleys and belts. FIG. 29.

TENSIONING THE DRIVE BELTS

3. Check the

Cutterhead Drive Belt (#222, FIG. 30, A)

tension with thumb pressure. The drive belt should not give

more than 3/8" in the center. FIG. 31.

4. From outside, rear of the machine, loosen the four Nuts

(#223, FIG. 32) that secure the motor in place. Lift the

motor to slacken the tension on the drive belt, or move it

down to increase the belt tension.

5. When the belt tension is correct, tighten the motor

mounting nuts that were done in step 4.

6. The

Feed Roller Belt (#220), FIG. 30, B) is automati-

cally tensioned with the Spring (#248, C) and requires no

adjustments.

7. The

Feed Roller Chain (#228, FIG. 30, D) is factory set

and should not require any setting changes. However, to

increase or decrease the chain overlap, the Bearing with

Sleeve (#230, E) can be adjusted in or out with Bolt & Nut

(#233, 229).

NOTE: While the side panel and cutterhead cover are

open, remove any chips and dust that may have accumu-

lated with a dust collector or brush.

8. When all belts have been checked and any maintenace

has been done, replace the side panel and belt cover and

secure them in position with the screws.

REPLACING THE DRIVE BELTS

1. To replace the

Drive Belt (#222), follow the same steps,

#3-5 above. Loosen the tension until the belt can be easily

removed from the Motor Pulley (#221) and Cutterhead

Pulley (#235). Once removed, reverse the steps to install

and re-tension the new belt on the pulleys.

2. To replace the

Feed Roller Belt (#220), the Drive Belt

must first be removed. With the motor loose and lifted,

there should be enough slack to install a new Feed Roller

Belt. If not, the tensioning Spring (#248) can also be

un-hooked to allow the Cam Wheel Bracket (#244) to

swing loose. Re-fastened the spring once the belt has

been installed. Then reverse the steps to install the drive

belt and re-tension it on the pulleys.

3. When all work on the belts has been done, replace the

side panel and belt cover and secure them in position with

the screws.

D

Drive Belt Adjustment continued from page

16

FIG. 30

FIG. 32

FIG. 31

MOTOR

MOUNTING

NUTS

A

B

C

D

E