Operation, Fig. 36 fig. 37, Fig. 38 fig. 39 – RIKON Power Tools 25-200H User Manual

Page 19

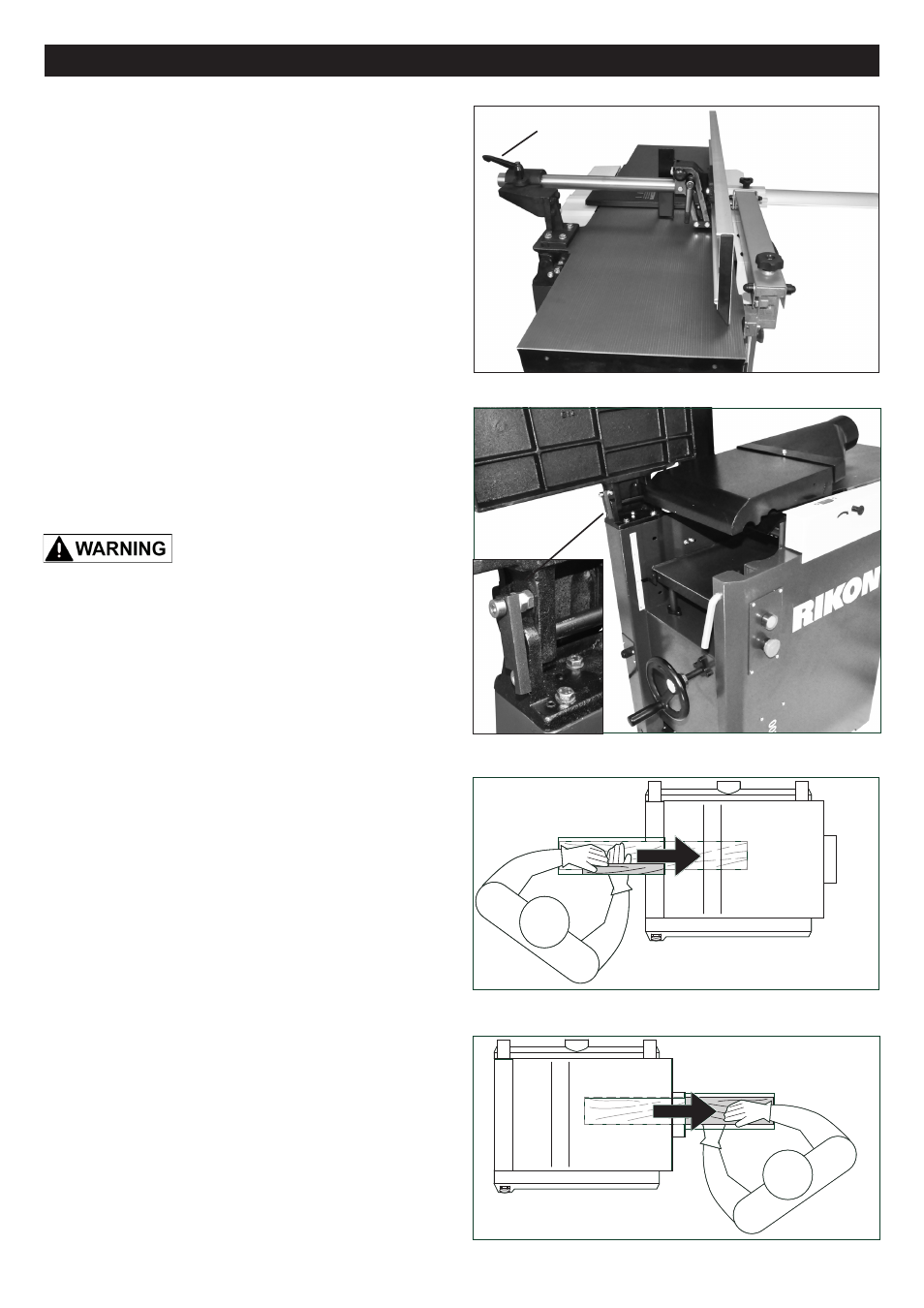

PLANER OPERATION

Thickness planing is used to reduce a workpiece with one

already surface planed surface to a desired thickness.

To use the planer, the upper, outfeed jointer table & fence

assembly must be tilted up and out of the way. FIG. 37.

1. Pull the jointer fence fully forward, and tighten the

locking handle (FIG. 36, A)

2. Twist the clamping Handle (#143, FIG. 37, B) up and

then pull it outward to release the outfeed table. Swing the

table (C) and fence assembly up and to the back of the

machine. Make sure the outfeed table's locking Bracket

(#147, D) is engaged to keep the table in the upward /

open position.

NOTE: When closing the outfeed table,

don't forget to release the locking bracket, or damage to

the machine may occur.

3. Pivot the Dust Chute (#30, FIG. 37, E) up and over the

jointer infeed table where it will automatically lock in place

with the Locking Pin (F). Attach your dust collector's 4"

hose to the dust port before any planing is done.

It is extremely important that a dust

collection system is used with this planer to eliminate

harmful airborne dust, prevent the build-up of chips that

may jam the roller system in the cutterhead, and to keep

the working area clean of debris.

To use the planer:

- The board surface that has been already jointed flat

rests down onto the planer's table.

- The board will be cut on its upper surface by the

cutterhead as it passes through the planer.

- When planing, the feeding direction of the workpiece is

left-to-right under the cutterhead. FIG. 38.

NOTE: Workpiece dimensions for planing;

- Length: minimum 12"; for lumber over 60" use roller

supports.

- Width: maximum 12".

- Thickness: minimum 1/4"; maximum 8".

- Depth of Cut: maximum 1/8". Multiple cuts of 1/16" or

less, produce better finish results.

A

19

FIG. 36

FIG. 37

OPERATION

FIG. 38

FIG. 39

1. To feed the workpiece into the machine, assume

proper operating position, FIG. 38. Stand offset to one side

of the feed opening to avoid any kick-back, should it occur.

Do not push the lumber once the infeed roller has been

engaged. Let the infeed roller move the workpiece into the

planer at its own pace.

2. To remove the workpiece from the machine, position

yourself offset to one side of the outfeed opening. FIG. 39.

Do not pull the lumber as it exits the machine. Let the out-

feed roller move the workpiece out of the planer at its own

rate, but support the lumber as it extends past the exten-

sion rollers, if needed.

continued page 20

B

C

D

E

F