Adjustments, Fig. 17 – RIKON Power Tools 25-200H User Manual

Page 12

12

ADJUSTMENTS

ROTATING OR REPLACING KNIFE INSERTS

This machine has a helical cutterhead with four rows of

carbide knife inserts. Each of the 56 inserts on the

cutterhead are indexed and have four sharpened sides.

If the knives become dull, or one becomes nicked, simply

loosen the retaining screws with the supplied star head

screwdriver, lift up and rotate the inserts to a new sharp-

ened edge. No setting is required, as the cutterhead has

been machined to automatically index and set the inserts in

proper position for use. When all four sides of an insert are

dull, the insert can be easily removed and a new carbide

insert placed in the location.

To rotate or remove a carbide insert knife:

1. Unplug power cable.

2. Remove the Screw (#350), that holds the Insert in the

cutterhead, and the Insert knife (#349). FIG. 14.

3. While the insert is removed, clean any resin buildup or

trapped dust from the surfaces of the cutterhead with a

suitable solvent. A tooth brush works well for safe cleaning

around the sharp inserts. Any accumulated dust can affect

the seating of the insert in the cutterhead.

4. Rotate the insert so that a new sharpened edge is in

position. The inserts have a indication mark on their top

surface corner, so that you can reference the positioning of

the insert's dulled or sharpened edges. FIG. 14, 15, 16.

5. Tighten the insert's set screw to lock the insert back in

position. DO NOT overtighten the screw or damage to the

insert may result. Torque to 50-55 in/lbs.

6. Plug in the power cable when you are ready to

resume jointing and planing.

FIG. 15

FIG. 16

FIG. 14

CARBIDE INSERT

KNIFE HAS 4

SHARP EDGES

INDEX MARK

STAR HEAD

SET SCREW

JOINTER TABLE ALIGNMENT

For the best surfacing of workpieces, the jointer's infeed

and outfeed tables must be set at the same level to form a

large 'flat' surface. These tables must also be in alignment

with the cutterhead for true surfacing, when you measure

the flatness of a board from side-to-side and end-to-end.

The machine has been factory set before shipping - the

infeed table being set to the cutterhead knives, and then

the outfeed table set to the infeed table. But once the ma-

chine has been set in its final location in the shop, the table

alignments should be checked to make sure that there has

been no movement during its handling.

1. Position and lock the infeed table at its high '0" ' setting,

so that it should be level with the outfeed table.

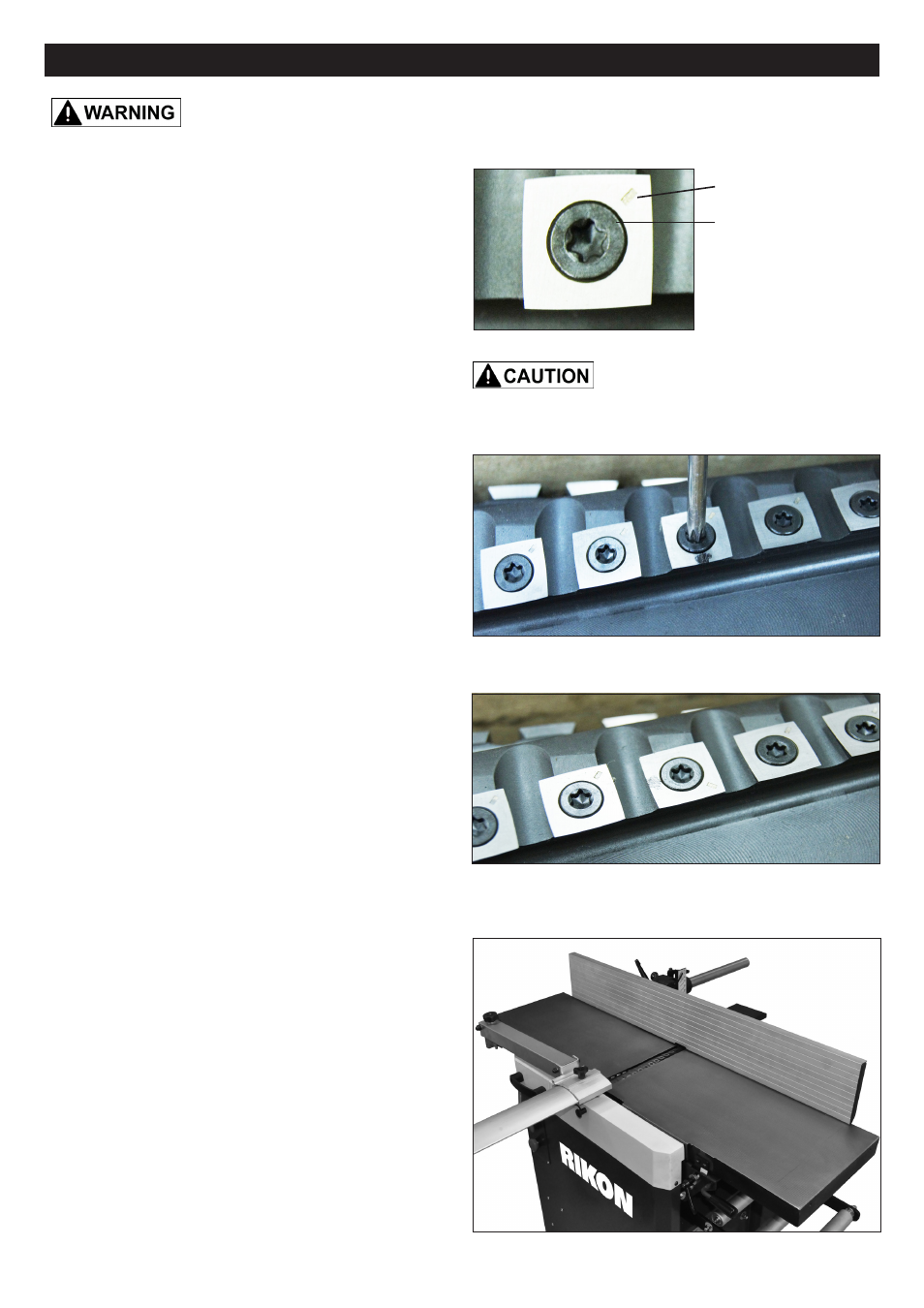

2. Slide the fence and cutterhead guard to the sides and

off the tables to reveal the whole table surfaces. FIG. 17.

THE MACHINE MUST NOT BE PLUGGED IN AND THE POWER SWITCH

MUST BE IN THE OFF POSITION UNTIL ADUSTMENTS ARE COMPLETE.

FIG. 17

Wear gloves when changing knife

inserts to avoid the risk of personal injury by cuts that may

result from touching the sharp edges!

continued on page 13