Site selection & preparation, Arch assembly – Rhino Shelter ROUND-30W X 40L X 15H User Manual

Page 3

Assembly Instructions

30x40x15 Round Style Portable Building With Single Door

3

Version 2.0

Please DO NOT return unit to store or dealer. For all questions or shortages please contact

Customer Service at: 800-447-7079 or 203-877-7070

SITE SELECTION & PREPARATION

Select a level or as close to level as possible location for

your MDM Products Building. As the components fit into

each other as a level unit, there can be no more than 1

inch difference between one base flange and another.

Time spent preparing the base will pay off in years of

good operation without binding of parts and doors.

The best location is on top of a poured concrete pad. At

minimum, the building should be placed on a base of

materials suitable for the storage load to be protected. If

not on concrete, typical construction would be a 6” bed

of crushed process rock, compacted with a vibrating

compactor, with blocks underneath the location of the

base flanges. Sides can be mounted on top of wooden

timbers or piles driven into the ground at the correct

elevation.

The unit should not be located under trees, which will

shed hard fruit such as apples, walnuts, or heavy

pinecones. The cover of your unit will protect against

normal falling leaves and light debris; however, large

branches or other falling items may cause a puncture or

tear in the cover material.

Take notice of drainage around your intended location.

Water draining from the surrounding terrain should be

planned so that it does not run into the unit. As well, rain

or melting snow that comes off the unit should be

drained away rather than accumulate and pool around

the unit.

Check to be certain that adequate clearance is allowed

for entry and exit.

When selecting a location for the building, consideration

should be taken of the ability of the ground to keep the

base flanges in place, as well as support the weight of

the building and content. Using the stakes and string,

measure off and square area for intended installation.

Level the ground as best as possible. A properly leveled

frame yields maximum strength.

ARCH ASSEMBLY

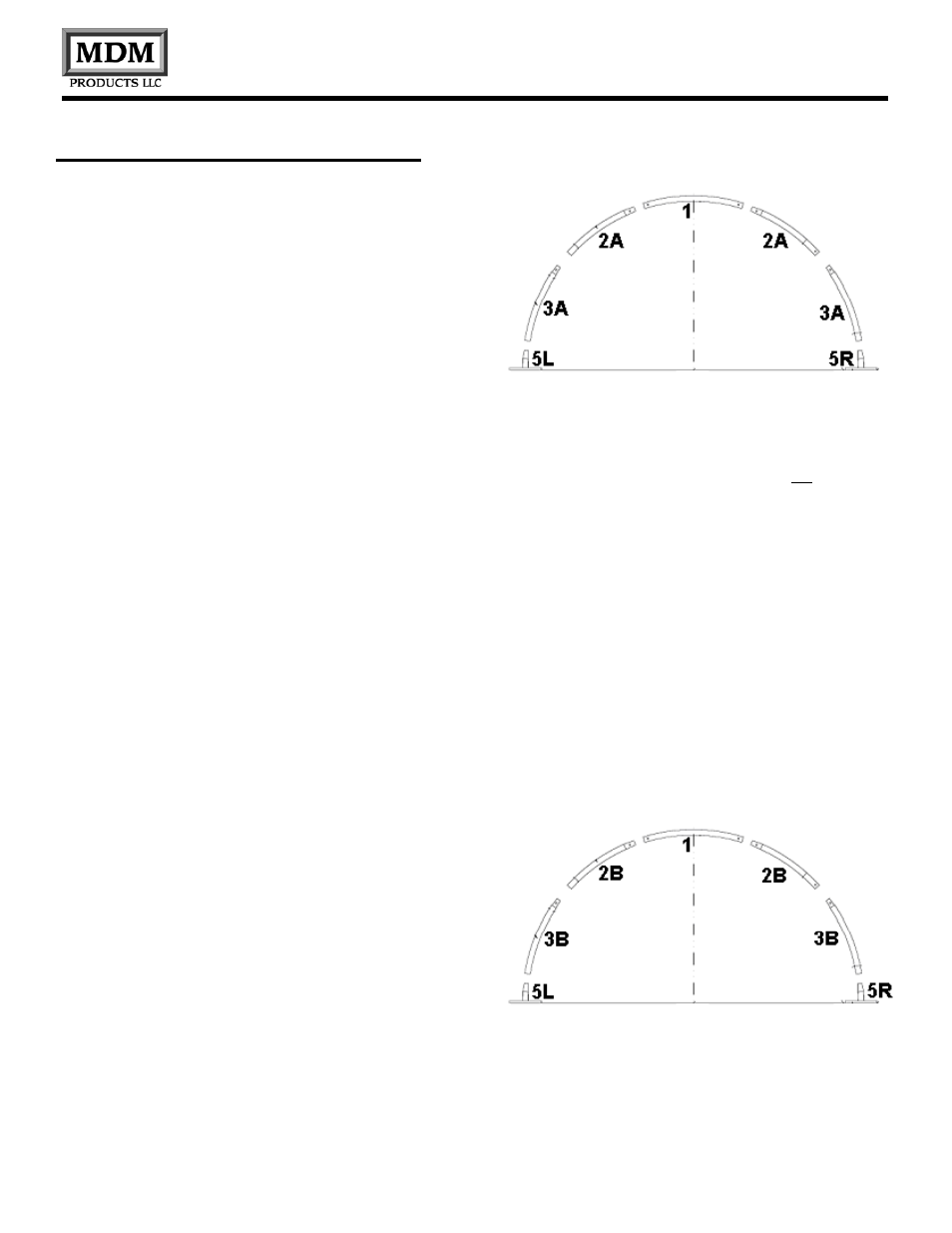

Step #1 – Assemble Arches

Unit consists of One Front Arch, Five (5) Interior Arches,

and One Rear Arch. Assemble each arch on ground.

Begin by laying out the components of the Front Arch.

Front Arch consists of:

One (1) Top Ridge Tube (1)

Two (2) Front Wall Curved Roof Tube (2A)

Two (2) Front Wall Sidewall Tubes with Wind Brace

supports (3A)

Components slide into each other at the ends. Sidewall

tubes (3A) must be faced so the clips for Wind Brace

Supports are facing to the next interior arch. Secure

them together using 10mm x 75 mm Carriage Bolt,

washer, and nuts. Only snug up nuts, do not over

tighten nuts.

Use 10mm x 75mm Bolts with Washers and Nuts

through pre-drilled holes in frame members. Be certain

to insert carriage bolts from the outside into the interior

of the unit, with the washers and nuts on the inside of

the frame. This will prevent the bolts from puncturing

through the cover material. Do not tighten down the nuts

completely until frame is fully assembled and set in

place.

Assemble Rear Arch in same manner. Rear Arch

consists of:

One (1) Top Ridge Tube (1)

Two (2) Rear Wall Curved Roof Tube (2B)

Two (2) Rear Wall Sidewall Tubes with Wind Brace

supports (3B)

Assemble each of the five (5) Interior Arch Assemblies.

Refer to Figure 1 Frame Assembly to review Interior

Arch #2 and #6 requirements (directly inside End

arches). These aches must have the Sidewall Tubes