6 pid tuning constants, 7 controller calibration – LumaSense Technologies M390S User Manual

Page 17

M390S Manual

Operation 17

4.6 PID Tuning Constants

The PID tuning constants have been factory set for optimum performance and are noted below.

Heating

Heating 2

Heating 3

Heating 4

PB _____

PB2 _____

PB3 _____

PB4 _____

INTEGRAL

_____min/repeat

INT2

_____

INT3 _____

INT4 _____

DERIVATIVE___sec

DERV2

_____

DERV3

_____

DERV4

_____

4.7 Controller Calibration

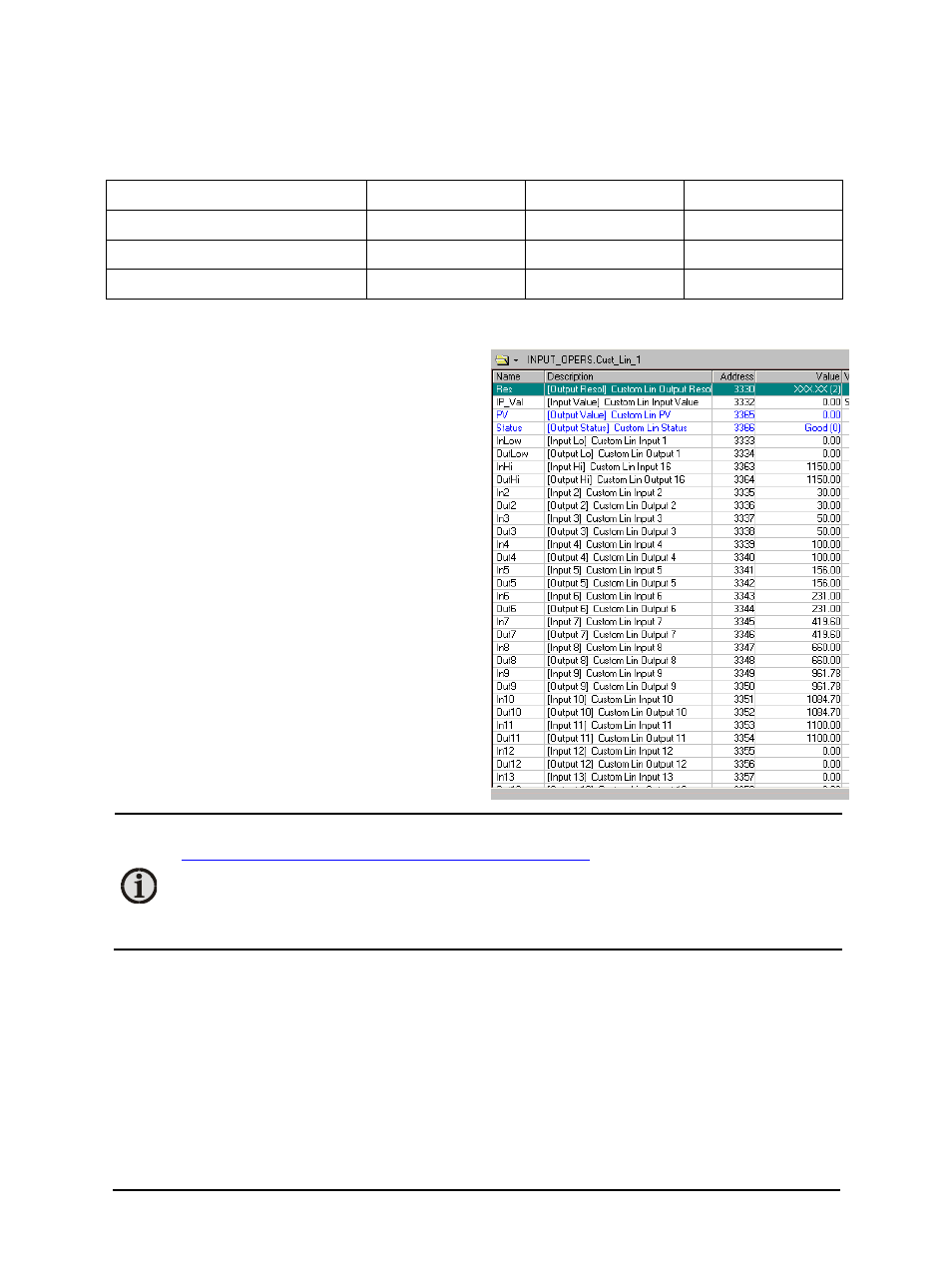

This blackbody has a precision temperature

sensor monitoring the emitter temperature. The

THERMOCOUPLE measurements are passed

through a look-up table that ultimately

provides the correct exit radiance temperature

for the indicated temperature. A separate

calibration report is included.

This controller has been programmed to contain

a custom look-up table that may be used to

precisely calibrate the controller/indicator

against reference sensor. The look-up table to

the right appears as shown in the controller GUI

interface (not supplied).

The logic of this table is: “when the sensor input

measures the value shown in INPUT #, force the

display to show the value in the corresponding

OUTPUT # and do linear interpolation between

points”. A sample table is shown to the right.

The actual table used for your calibration is

shown on the next page.

Follow directions on the next page to alter

output values from the controller front panel.

Note: You may download Eurotherm iTools Software from this web site:

With this software and some practice, you will see this GUI interface screen. To permit

iTools to talk to your blackbody, you may have to set the controller comm. port to

“Modbus” mode. Procedure to change communications to Modbus are shown in

Section 4.8.