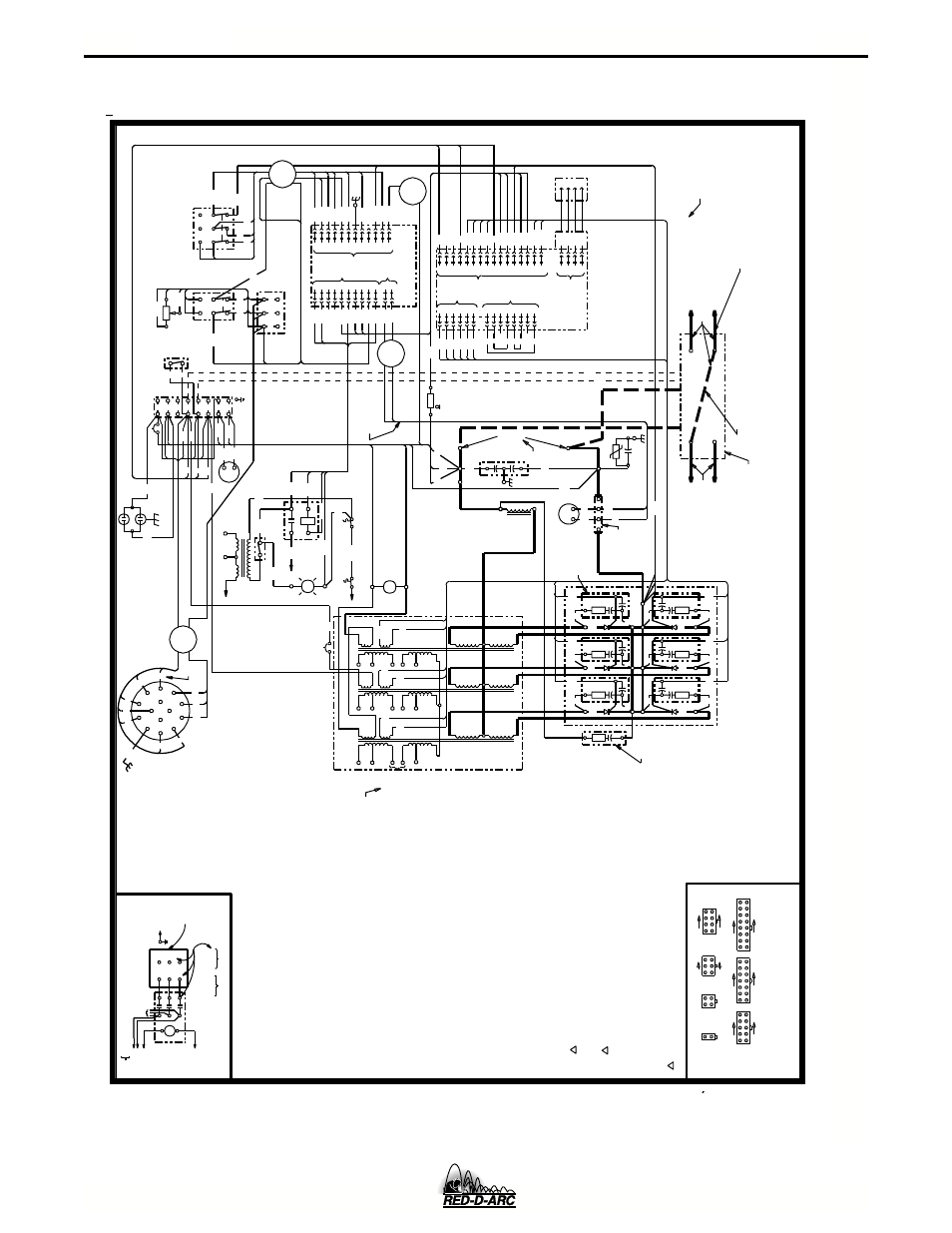

Diagrams, Dc-600 – Lincoln Electric IM657 RED-D-ARC DC-600 User Manual

Page 40

F-1

DIAGRAMS

F-1

DC-600

NOTES:

N.D. WELDING CABLE MUST BE OF THE PROPER

CAPACITY FOR THE CURRENT AND DUTY CYCLE

OF IMMEDIATE AND FUTURE APPLICATIONS.

"POSITIVE". TO CHANGE THE POLARITY, TURN

THE DC-600 OFF, AND REVERSE THE LEADS AT

THE MULTI-PROCESS SWITCH.

CONNECTION DIAGRAM, CONNECT ELECTRODE

AND WORK LEADS TO THESE TERMINALS

INSTEAD OF THE POWER SOURCE

OUTPUT TERMINALS.

THESE NOTES APPLY ONLY TO DC-600 WITH A

MULTI-PROCESS SWITCH INSTALLED.

N.E. THIS DIAGRAM SHOWS THE "STICK" POLARITY

N.F. USING A WIRE FEEDER, K-317 OR K-318

6 5

4

9

8

7

TO PRIMARY COILS

CODE

ELECTRICAL

RECONNECT

PANEL

ELECTRICAL SYMBOLS PER E1537

1

2

12

34

13

4

6

1

1

61

0

5

1

4

8

5

8

J3

J5

J7

CONNECTOR CAVITY NUMBERING SEQUENCE

(VIEWED FROM COMPONENT SIDE OF BOARD)

J6

J4

J2

1

8

J1

H1

TO

SUPPLY

LINES

L3

L2

L1

271

H2

272

CR1

INPUT

CONTACTOR

226

238

236

R1

237

75

10K 2W

215

232

224

81

77

76

76

75

77

T.S.1

80

280

210

215

1

2

3

4

5

6

7

8

9

1

2

233

256

231

255

J2

J3

CONTROL

P.C. BOARD

1

1

2

2

33

4

4

5

5

6

6

7

8

9

J4

J5

P.C. BOARD

2

4

215

+

-

WORK

ELECTRODE

TO STICK ELECTRODE HOLDER OR

AIR-CARBON ARC TORCH

TO "WORK" USED WITH STICK

OR AIR-CARBON ARC

STICK WORK LEAD NOT

USED WHEN JUMPER IS

USED.

OPTIONAL USER SUPPLIED JUMPER FOR

THOSE SITUATIONS WHERE IT IS NOT

CABLES FOR STICK AND SEMI-AUTOMATIC

WELDING.

N.D.

N.E.

N.D., N.F.

OPTIONAL

MULTI-PROCESS

SWITCH

210

210

210

215

OUTPUT SHUNT

(50MV @800 AMPS)

OUTPUT

CHOKE

C7

222

OUTPUT

N.D.

(+)

(-)

R2

32A

31

FAN

MOTOR

272

273

SEC. LEAD

THERMOSTAT

256

PRIMARY THERMOSTAT

256

PILOT

LIGHT

233

235

255

B

5

7

A

271

W

S

S

F

F

32A

207

208

3

18

6

9

S

F

205

206

2

14

5

8

AUX. 1

S

F

203

204

F

31

S

AUX.2

16

PRI.

4

7

PRI.

SEC.

SEC.

SCR

SCR

SCR

SCR

SCR

SCR

1

2

3

4

5

6

OUTPUT

SNUBBER

G6

G4

G2

OUTPUT RECTIFIER

ASSEMBLY

SCR

SNUBBERS

+

-

G1

G3

G5

NECESSARY TO HAVE SEPARATE GROUND

A

AA

A

A

A

CC

C

C

C

C

N.G.

1

CR2

10

J7

1

2

3

4

5

6

7

8

10

11

12

1

2

3 4

J6

A

B

B'

C

C'

A'

G1

G2

G3

G4

G5

G6

208

207

206

205

261

262

263

342

P22

13

14

15

16

FIRING CIRCUIT

215

231

214

203

204

TWISTED

TOGETHER

1

2

3 4

J23

FOR OPTIONAL

222

214

PARALLELING

KIT

30 100W

41

2

4

.05

.05

mFd

mFd

S3

CONTROL

OUTPUT

SWITCH

LOCAL/

REMOTE

WELDING MODE

SWITCH S4

(SHOWN IN CC

STICK POSITION)

FAULT

PROTECTION

RELAY

42A

S

F

41

42

BREAKER

10A

CIRCUIT

21

41

4

31

32

21

-

+

32A

2

S2

OUTPUT

TERM.

SWITCH

4

2

T.S.2

T1 MAIN TRANSFORMER

2

4

41

237

236

+

-

AM

210

215

32

31

DUPLEX (ON 60 HZ MACHINES ONLY)

255

X1

X2

T2

H1

H2

H3

CONTROL TRANSFORMER

+

-

VM

222

210

AJ

K

N

L

M

I

H

G

B

C

D

E

F

14 PIN

(FRONT

RECEPT.

75

76

77

21

41

31

42

32

2

4

GND

42

222

222

222

210

N.C.

MAY VARY. SEE IM MANUAL FOR LOCATION.

N.C. LOCATION OF THIS LEAD ON T.S.2 TERMINAL STRIP

7

14

8

16

VIEW)

S1

SWITCH

42

15A

BREAKER

CIRCUIT

229

290

291

291

290

PER NATIONAL

TO GROUND

41

G3506-1

DC-600

WIRING DIA

GRAM-230/260/575

V 60HZ ONL

Y

13

17

15

N.G. TAPE UP SEPARATELY TO PROVIDE AT

LEAST 600V INSULATION.

230/460/575V

(SHOWN CONNECTED

FOR LOW VOLTAGE)

3

2

1

15,14,13

18,17,16

N.G.

N.G.

H3

H4

N.G.

ALL PRIMARY

LEADS TO

RECONNECT

PANEL

INPUT POWER

255

229

280

215

1

2

3

4

5

6

80

232

75

222

J1

7

8

9

10

11

12

224

81

226

238

235

R.F.

CHOKE AS'BLY

R.F.

CHOKE AS'BLY

R.F.

CHOKE AS'BLY

R.F.

CHOKE AS'BLY

8-2000J

320V

160J

TP1

.05mFD

600 V

C1

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. G

ive the equipment code number..