Operation, Auxiliary power, Warning – Lincoln Electric IM660 RANGER 200 User Manual

Page 19

Stick Welding

The RANGER 200 can be used with a broad range of

DC stick electrodes.

TIG Welding

The RANGER 200 can be used for limited DC

Tungsten Inert Gas (TIG) welding applications using

the scratch start procedure. Start the arc while the

engine is running at low idle. TIG welding is normally

done with electrode negitive.

ARC GOUGING

Set the CONTROL knob to adjust output current to the

desired level for the gouging electrode being used

according to the ratings in the following table.

Electrode Diameter

Current Range (DC, electrode

positive)

1/8"

30-60 Amps

5/32"

90-150 Amps

3/16"

150-200 Amps

AUXILIARY POWER

Start the engine and set the IDLER control switch to

the desired operating mode. Full power is available

regardless of the welding control settings providing no

welding current is being drawn.

The auxiliary power of the RANGER 200 consists of

two 20 Amp-120 VAC (5-20R) duplex receptacles and

one 50 Amp 120/240 VAC (14-50R) receptacle. The

240 VAC receptacle can be split for single phase 120

VAC operation.

The auxiliary power capacity is 6,000 watts of 60 Hz,

single phase power. The auxiliary power capacity rat-

ing in watts is equivalent to volt-amperes at unity

power factor. The max permissible current of the 240

VAC output is 25 Amps. The 240 VAC output can be

split to provide two separate 120 VAC outputs with a

max permissible current of 25 Amps per output to two

separate 120 VAC branch circuits (these circuits can-

not be paralleled). Output voltage is within ± 10% at

all loads up to rated capacity.

The 120 V auxiliary power receptacles should only be

used with three wire grounded type plugs or approved

double insulated tools with two wire plugs. The cur-

rent rating of any plug used with the system must be

at least equal to the current capacity of the associated

receptacle.

NOTE: The 240 V receptacle has two circuits, each of

which measure 120 V toneutral but are of opposite

polarities and cannot be paralleled.

B-4

OPERATION

B-4

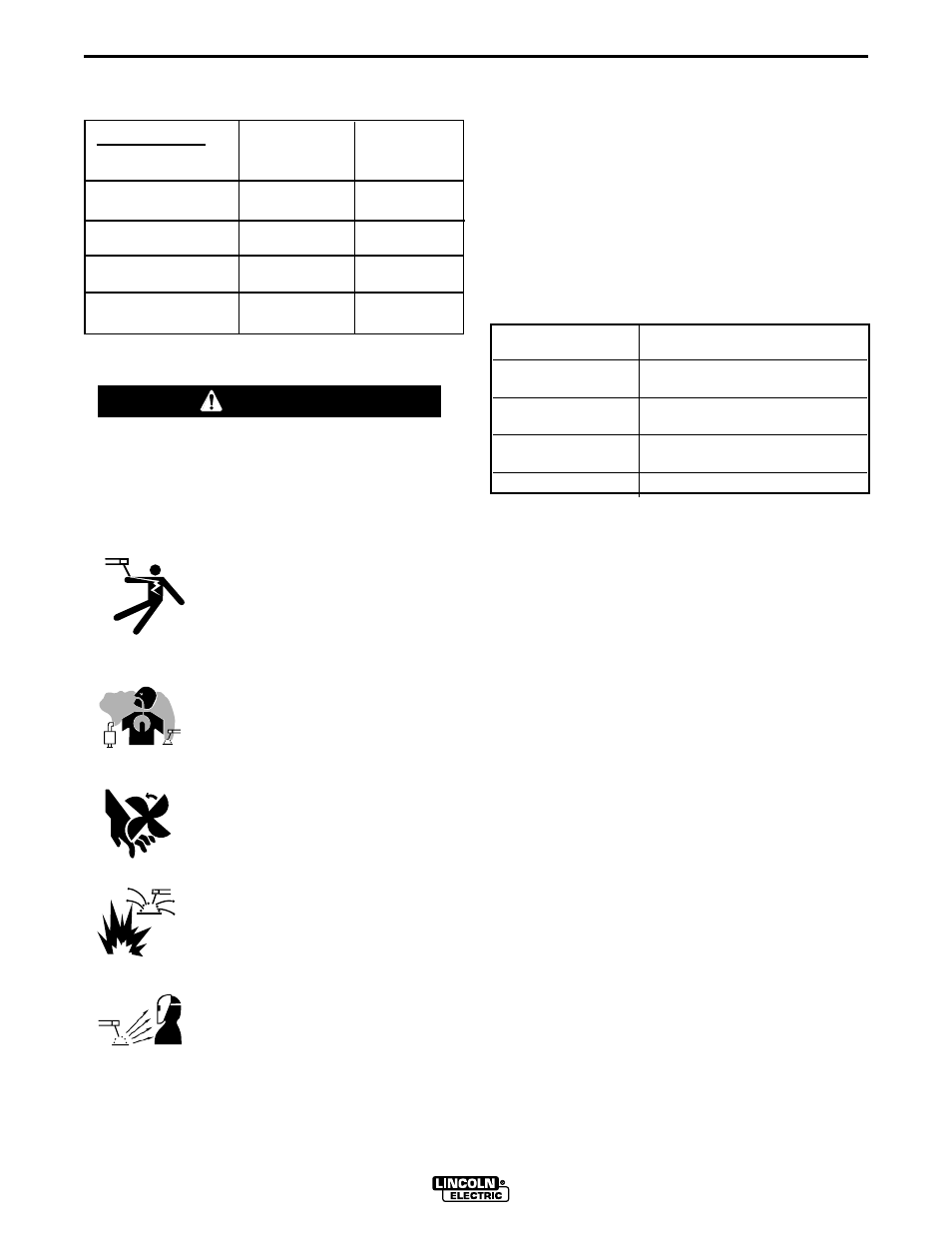

TABLE B.1

TYPICAL RANGER 200 FUEL CONSUMPTION

WELDING OPERATION

RANGER 200

Do not attempt to use this equipment until you

have thoroughly read the engine manufacturer’s

manual supplied with your welder. It includes

important safety precautions, detailed engine

starting, operating and maintenance instructions,

and parts lists.

------------------------------------------------------------------------

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and

ground

• Always wear dry insulating gloves.

------------------------------------------------------------------------

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing zone.

------------------------------------------------------------------------

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

------------------------------------------------------------------------

WELDING SPARKS can cause fire or

explosion.

• Keep flammable material away.

------------------------------------------------------------------------

ARC RAYS can burn.

• Wear eye, ear and body protection.

------------------------------------------------------------------------

See additional warning information

throughout this operator’s manual.

-----------------------------------------------------------

WARNING

KOHLER CH 15

Low Idle - No Load

2500 RPM

High Idle - No Load

3700 RPM

DC CC Weld Output

210 Amps @ 25 Volts

Auxiliary Power,

6,000 VA

15 HP@3600

RPM GAL./HR

(LITERS/HR.)

.25 gallons/hour

(.95 liters/hour)

.52 gallons/hour

(2.0 liters/hour)

1.1 gallons/hour

(4.1 liters/hour)

1.0 gallons/hour

(3.9 liters/hour)

RUNNING

TIME 12 GAL.

(HOURS)

48

23

11

12