Operation, Welding controls, Engine controls – Lincoln Electric IM660 RANGER 200 User Manual

Page 17

B-2

OPERATION

B-2

RANGER 200

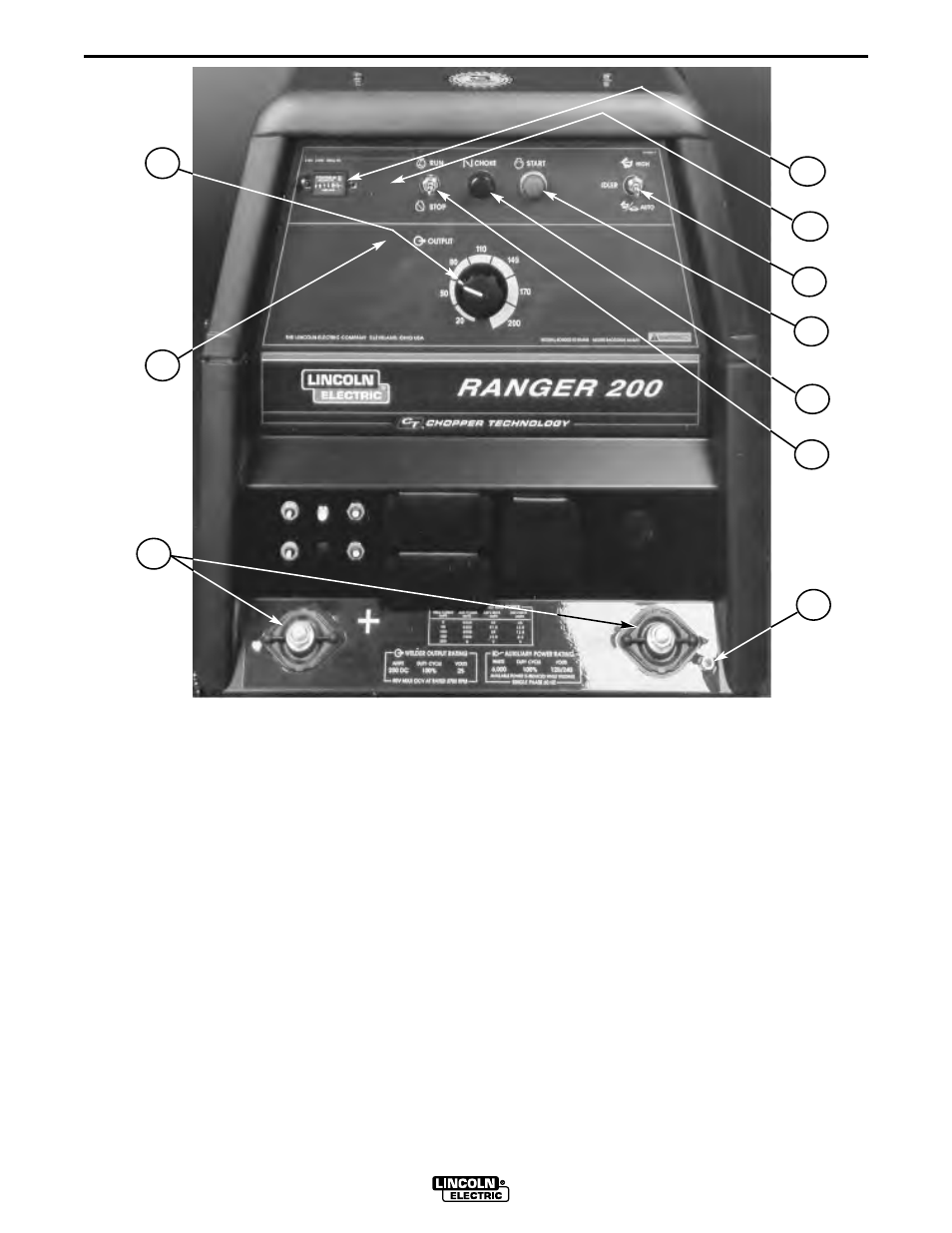

WELDING CONTROLS

1. OUTPUT CONTROL:

The OUTPUT dial pro-

vides continuous control of the welding current.

2. THERMAL SHUTDOWN INDICATOR

LIGHT: I

ndicates that the welding output is shut off

because of blocked airflow or the welding current

exceeded the rating of the machine

.

3. WELD OUTPUT TERMINALS WITH

FLANGE NUT:

Provides a connection point for the

electrode and work cables.

4. GROUND STUD:

Provides a connection point

for connecting the machine case to earth ground for

the safest grounding procedure.

ENGINE CONTROLS

5. RUN/STOP SWITCH:

RUN position energizes

the engine prior to starting. STOP position stops the

1

2

3

4

5

6

7

8

10

9

engine. The oil pressure interlock switch prevents

battery drain if the switch is left in the RUN position

and the engine is not operating.

6. CHOKE:

When pulled out, it closes the choke

valve on the engine carburetor for quick starting.

7. START:

PUSH BUTTON

-

Energizes the starter

motor to crank the engine.

8. IDLER:

SWITCH- Has two positions as follows:

1)

In the HIGH position, the engine runs at the high

idle speed controlled by the engine governor.

2)

In the AUTO position, the idler operates as fol-

lows:

A. When switched from HIGH to AUTO or after start-

ing the engine, the engine will operate at full speed

for approximately 12 seconds and then go to low

idle speed.