Step 2, Step 1a, Step 1b – Anthro Fit Adjusta Unit 60 Assembly Instructions User Manual

Page 3: Step 9, Step 10, Step 11, Detail view

Anthro

Corporation Technology Furniture

®

10450 SW Manhasset Drive Tualatin, Oregon 97062 1-800-325-3841

anthro.com

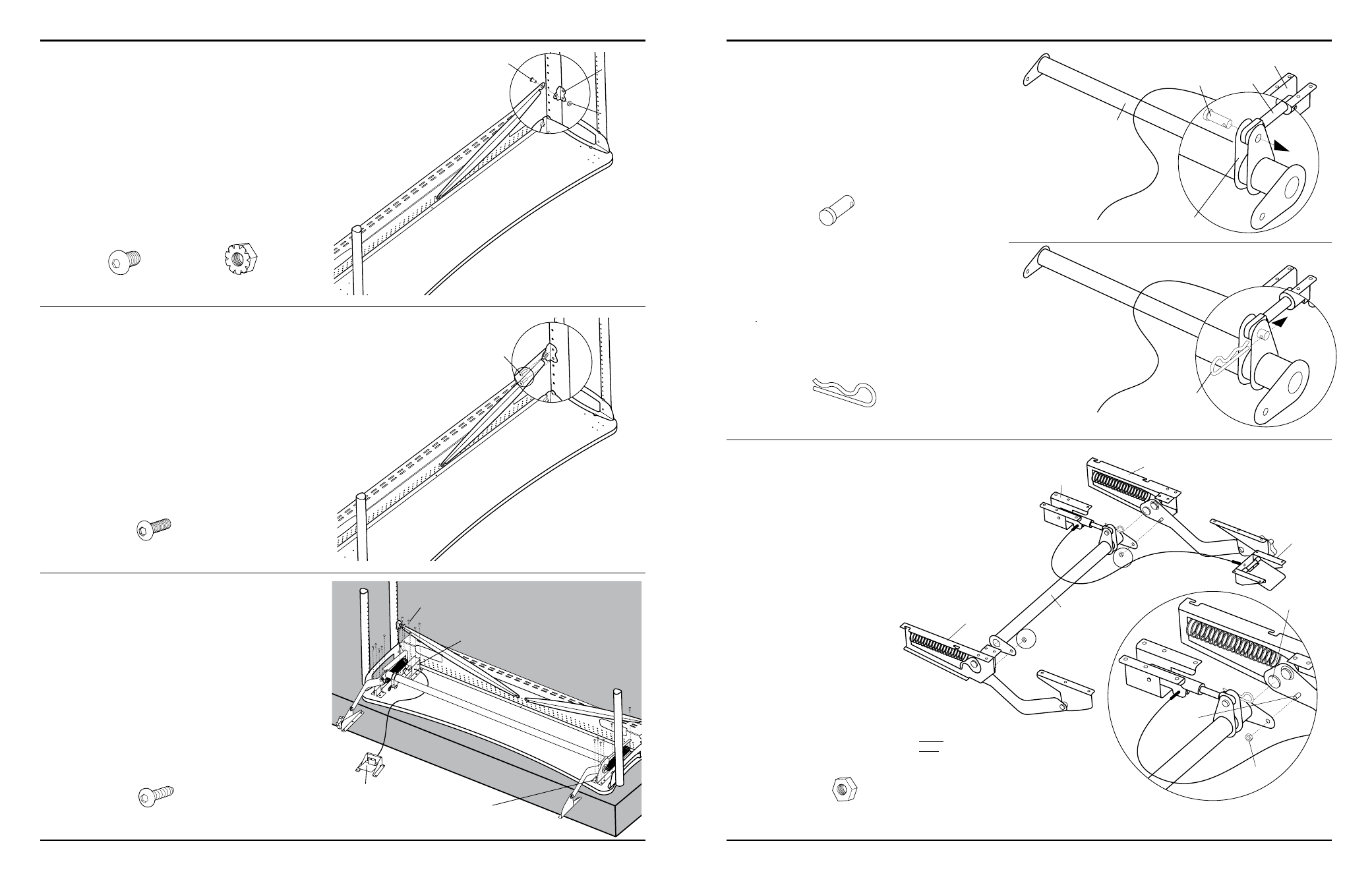

Step 2

(uses the 3-Way Wrench)

Unpack the remaining Adjusta Mechanism components

and arrange them as shown at right.

Place one Crossbar end onto the lower Crossbar

“Button” and Threaded Bolt (located on each of the Arm

Mechanisms). Secure the Crossbar to the Arm Mechanism

using one

5

/

16

" Hex Nut onto the Threaded Bolt.

Repeat for remaining Crossbar end and Arm Mechanism.

5

/

16

" Hex Nut

(included with 225-5548-00)

DETAIL VIEW

Arm Mechanism

Threaded

Bolts

5

/

16

" Hex

Nut

Paddle

Brake/Paddle

Assembly

Arm Mechanism

Crossbar

Lower Crossbar

‘Button’

NOTE: it is very important that you attach the Crossbar

ONLY to the Lower Crossbar Button.

Step 1a

Your Adjusta Mechanism comes un-assembled and is

boxed separately inside the Adjusta Unit package.

Begin to assemble the Mechanism by first locating the Adjusta

Crossbar and Brake/Paddle Assembly, position it as shown at

right. Depress the Paddle once to free the Brake Shaft.

Place the Brake Shaft between the two center Crossbar

Flanges. Insert the Post through both center Crossbar

Flanges and Brake Shaft.

Cotter Pin

(included with 225-5548-00)

Center Crossbar Flanges

Cotter Pin

Step 1b

Install the Cotter Pin through the single opening of the

Post to secure into place.

NOTE: included with Adjusta Mechanism is a small bag of

Hardware containing the (1) Post, (1) Cotter Pin, (2) Hex Nuts,

(2) Wood Screws, & (2) Cable Mounts.

Post

(included with 225-5548-00)

Brake Shaft

Brake/Paddle Assembly

Crossbar

Post

FAJ60zz/xx3

Step 9

Position a Cross End on the opposite end of the Buttress

installed during Step 8.

Insert a Button Head Screw from the rear of the Buttress,

through the Cross End and capture on the opposite side

using a Keps Nut.

NOTE: Just hand tighten the Keps Nut for now.

(

1

/

4

-20 X .50") Button Head Screw

325-5003-00

(

1

/

4

-20) Keps Nut

325-5130-03

Keps Nut

Button Head Screw

Cross End

Support Screw

325-5010-00

Step 10

(requires the 3-Way Wrench)

Rotate the Buttress and Cross End upward to align the

holes on the Cross End with two corresponding holes

on a Vertical Leg.

Secure the Cross End to the Leg using two Support Screws.

Repeat Steps 8, 9 & 10 for the remaining Buttress and

Cross End on the opposite side. Then, tighten all Screws &

Keps Nuts.

Support Screws

3

/

4

" Wood Screw

325-5106-00

Step 11

(requires Worksurface to be 12" from floor)

Place the Mechanism onto the Worksurface Assembly.

Align the Mechanism Flanges with the predrilled holes

on the Worksurface underside.

Secure the Mechanism to the Worksurface using a total of

twelve Wood Screws.

Align the six holes of the Brake Assembly with those

on the Worksurface. It may be necessary to depress the

Paddle while manipulating the Brake over the predrilled

Worksurface holes.

Secure the Brake Assembly using a total of six Wood Screws.

(12" high surface shown in shaded)

Paddle

Brake

Mechanism Flanges

Wood Screw