Stuart Turner Techflo TP 60TNH User Manual

Page 10

- 10 -

Cont ...

3.12

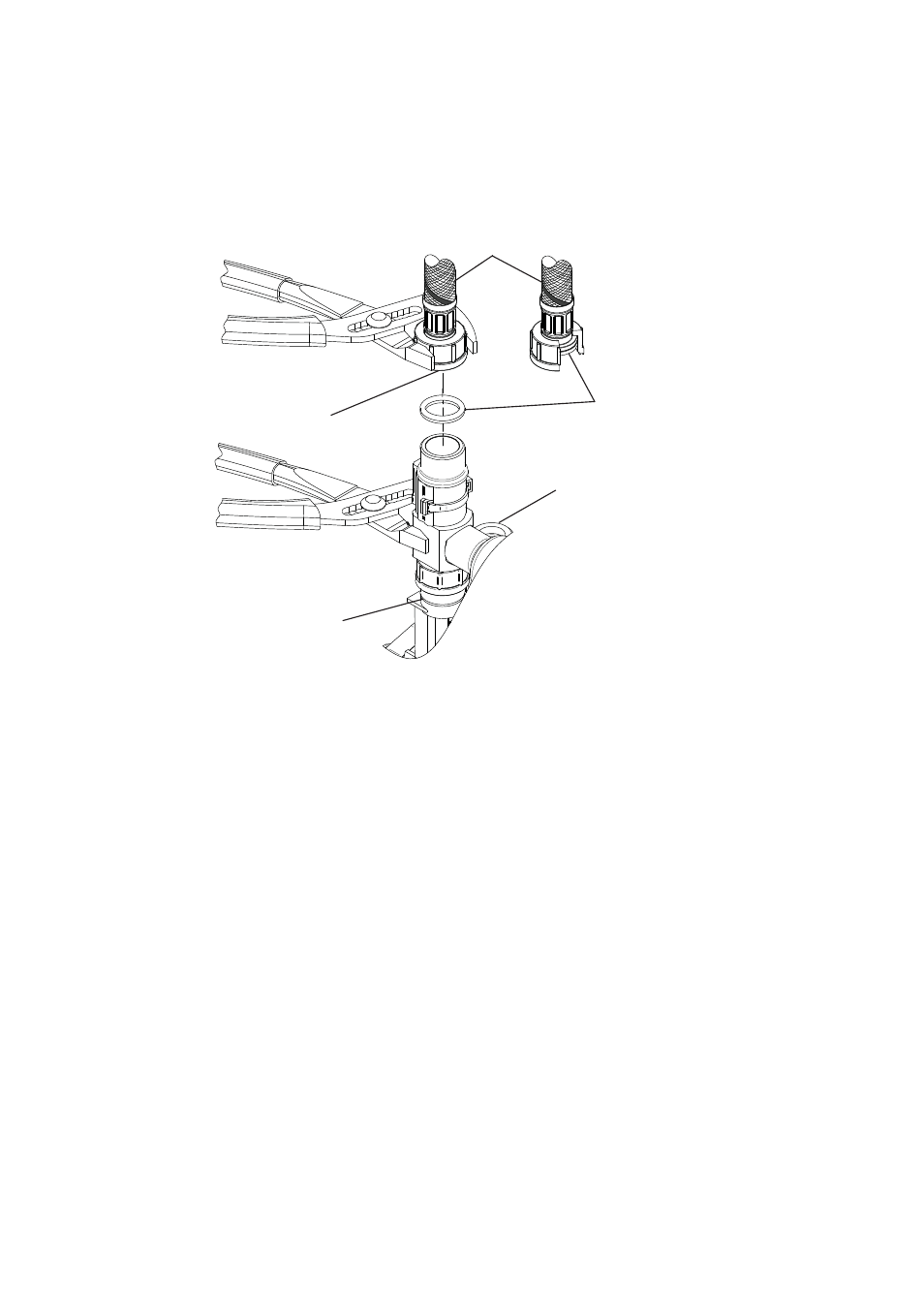

Hose to pump: The pump inlet and outlet ports have fittings which are

specifically designed for connection to the G ¾ female running nuts on the flexible

hoses. The hose end running nut is fitted with a rubber sealing washer which is

held captive within the nut assembly. Locate the hose into position and screw the

nut fully onto the fitting by hand. Finally nip tight with pliers (4 to 5 Nm)

for a water tight seal

(do not overtighten).

3.13

Hose to pipework:

1. The hoses are fitted with plastic push-in connectors, which must only be

connected with the following:

a) 15 mm diameter copper pipe to BS EN 1057 - R250 (half hard) - Table 3.

b) 15 mm plastic pipe to BS 7291 part 1 and part 2 (Table 1), or part 3

(Table 1) plus internal support sleeve*.

* The internal bore of the plastic pipe must be supported against collapse

with the pipe manufacturers recommended support sleeve (pipe insert).

c) Appropriate plumbing fitting that provides a leak tight connection.

Ensure the pipe is free from all score marks and deformities in the area of the

insertion depth (Fig. 10) and cut the pipe square, removing all burrs and sharp

edges to prevent damage to the sealing ‘O’-ring.

Fig. 9

Flexible hose

Rubber sealing washer

(captive in nut assembly)

Port fitting

Port adaptor (factory fitted)

G ¾ running nut

assembly