Stuart Turner Showermate U1.8 bar Twin User Manual

Page 10

- 10 -

Cont ...

3 PUMP

CONNECTIONS

Do not use stainless steel, chrome or nickel plated pipe with the

flexible hose push-in plumbing connections.

Do not introduce solder flux into the joint or surrounding area as

connectors will be attacked and may fail.

All solder joints should be completed and flux residues removed

before final connection to push-in connections, on the flexible hose.

Do not allow contact with oil or cellulose based paints, paint

thinners or strippers, acid based descalents or aggressive cleaning

agents.

Never operate pump with inlet and/or outlet isolating valves in the

closed position. Damage will occur!

3.11

Pumps supplied with flexible inlet and outlet hoses: Flexible pipes are

supplied with this pump variant. The pump inlet and outlet ports are threaded

G ¾ male. These ports are provided with a flat sealing face suitable for use with

an appropriately sized flat faced fitting and fibre or rubber washer. Ensure a

water tight seal is achieved when the pump is both stationary and running.

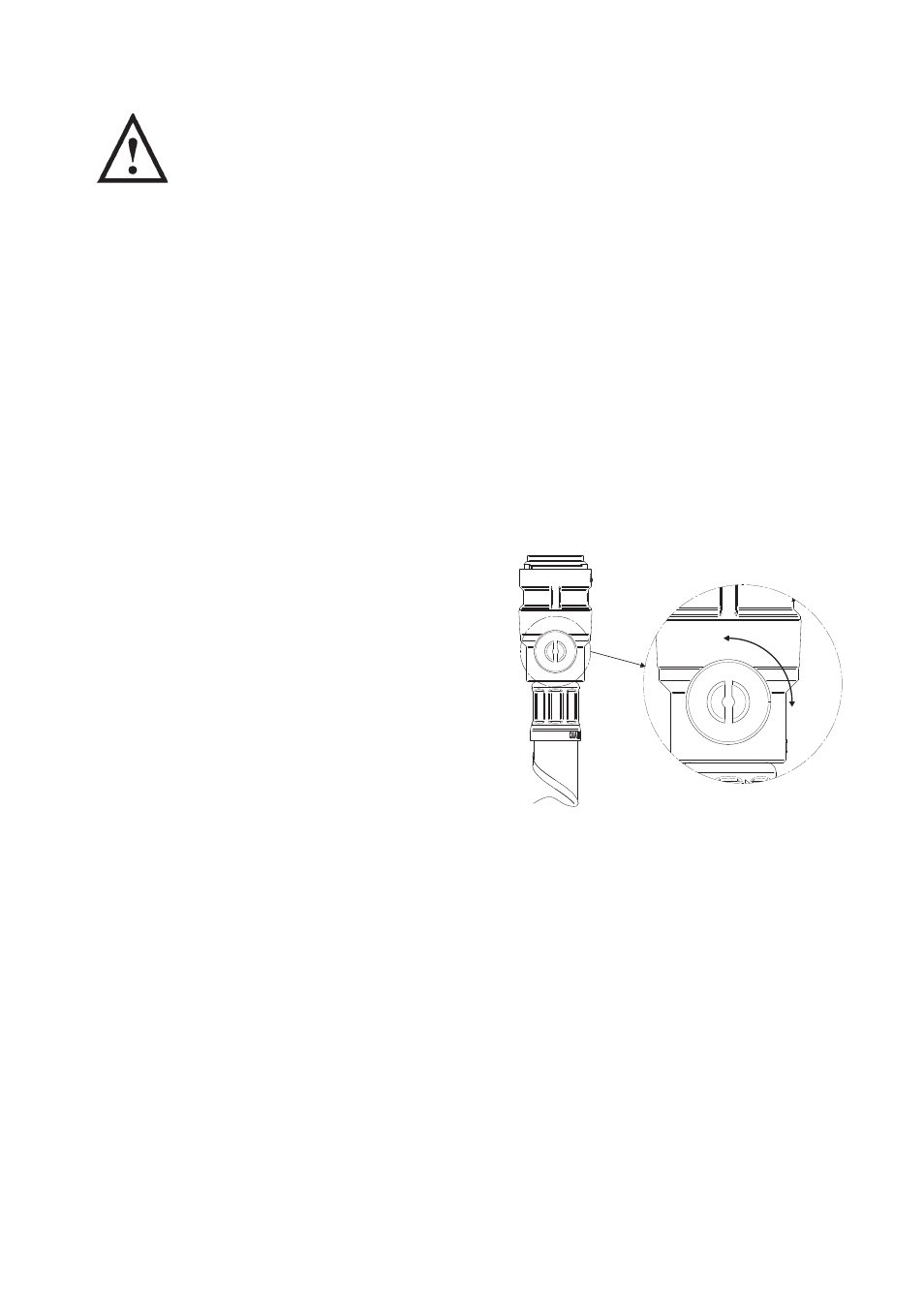

a) Hoses incorporating integral isolating

valves should be applied to the inlet

side of pump to satisfy servicing

requirements.

b) Standard hoses with no integral

isolating valve should be applied to

the outlet side of pump.

c) Use correct sized flat headed

screwdriver for opening and

closing integrated isolating valve to

prevent damage.

Please note these valves are of quarter turn design, rotate clockwise to close

and anti-clockwise to open. Failure to comply to these instructions could lead

to valve damage.

d)

WARNING - pump must not run with valve closed.

Open

Close

Fig. 8