3 pump connections – Stuart Turner Monsoon U1.5 bar Twin User Manual

Page 8

- 8 -

Cont ...

3 PUMP

CONNECTIONS

Do not use stainless steel, chrome or nickel plated pipe with the

flexible hose push-in plumbing connections.

Do not introduce solder flux into the joint or surrounding area as

connectors will be attacked and may fail.

All solder joints should be completed and flux residues removed

before final connection to push-in connections, on the flexible hose.

Do not allow contact with oil or cellulose based paints, paint

thinners or strippers, acid based descalents or aggressive cleaning

agents.

Never operate pump with inlet and/or outlet isolating valves in the

closed position. Damage will occur!

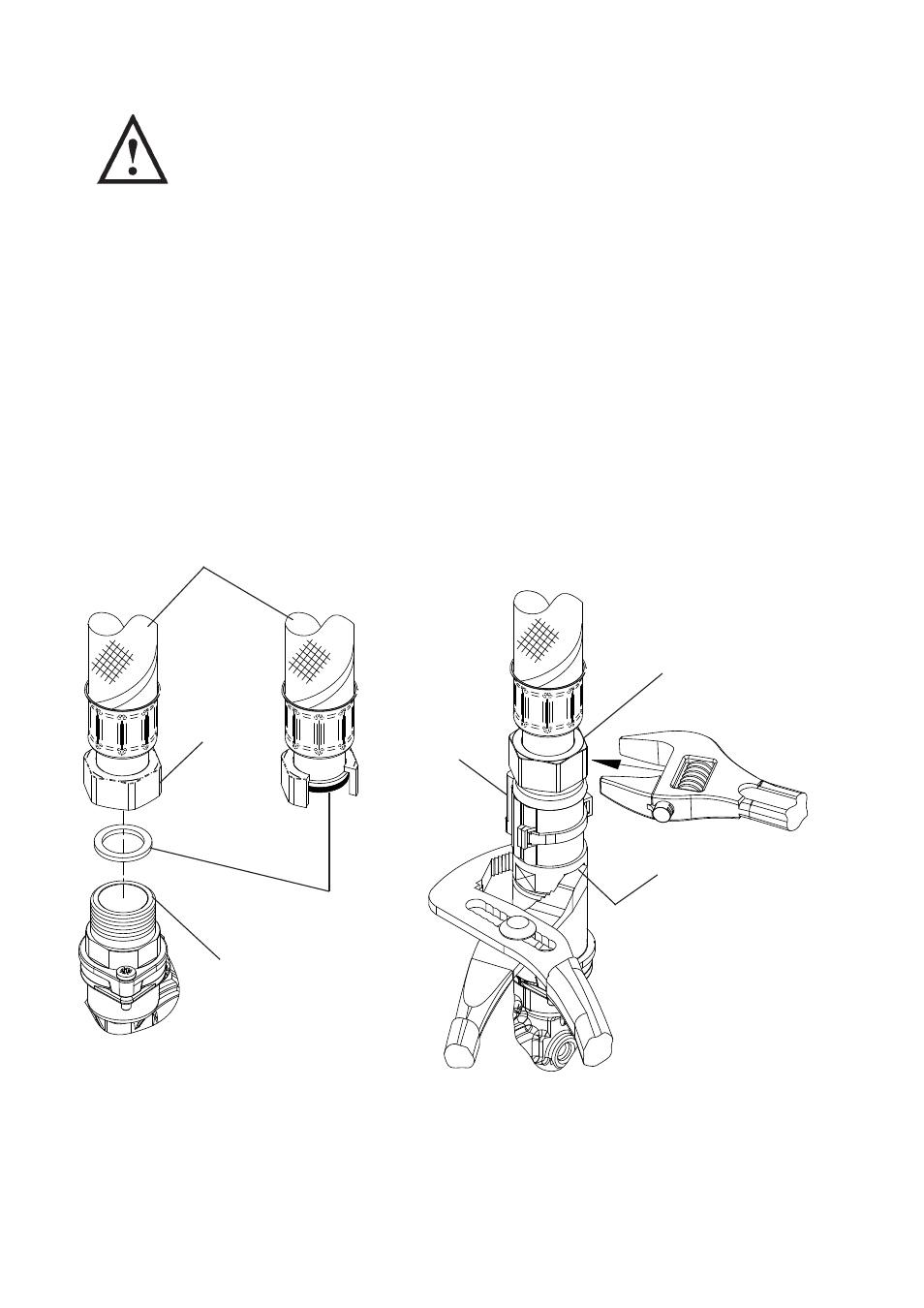

3.11

Hose to pump: The pump inlet and outlet ports have factory assembled fittings

which are specifically designed for connection to the G¾ female running nuts on

the flexible hoses. The hose end is fitted with a rubber sealing washer which is

held captive within the nut assembly. Locate the hose into position and screw

the nut fully onto the fitting by hand. Finally nip tight with a spanner (4/5 Nm)

for a water tight seal (

do not overtighten).

Fig. 6

Flexible hose

G ¾ running nut

assembly

Port fitting

Rubber sealing washer

(captive in nut assembly)

Reed

switch

clamp

assembly

29 mm AF

Anti-rotation flats

28 mm AF

Note: When tightening or loosening the

hose nut assembly, the anti-rotation

flats provided on the inlet and outlet

fittings should be used for placement of

a second spanner as shown. This is to

prevent complete assembly rotation.

It may be necessary to partially rotate

the reed switch clamp assembly on the

outlet fitting to avoid damage during

placement of the second spanner.