Turning a rotor – MAHLE RTI BRC40 User Manual

Page 17

Page 16

RTI

RTI

RTI

RTI

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

TECHNOLOGIES, INC.

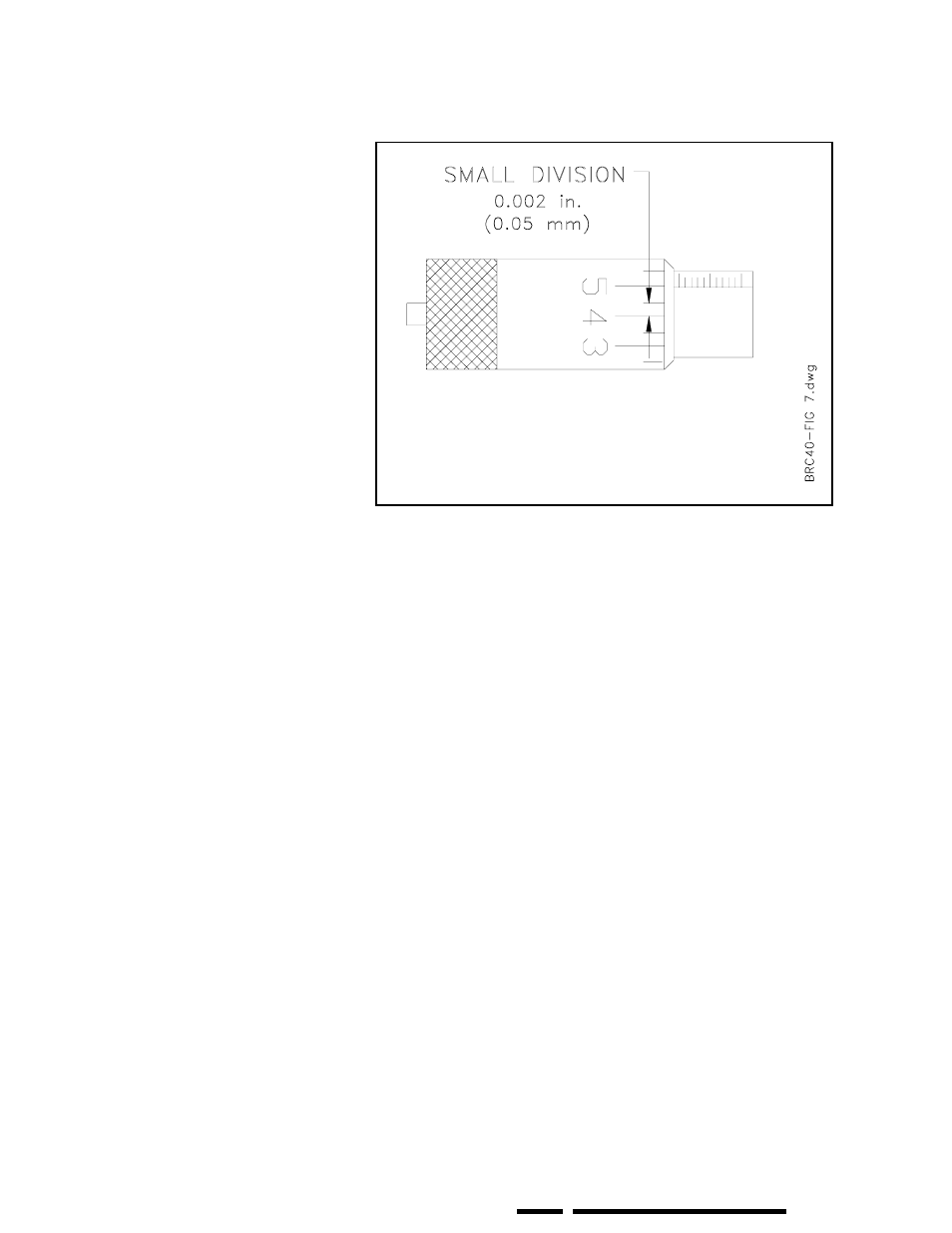

Figure 14 Cut Depth Micrometer

TURNING A ROTOR

18) When the cutting tools have moved

outward beyond the edge of the

rotor, press the bottom (OUTFEED)

of the Feed Direction Switch on the

lathe to place the switch in the OFF

position.

19) Momentarily turn off the Drive

Motor and check the surface of the

rotor. It should have a rough cut

surface across the entire face on both

sides. If not, make another rough cut,

otherwise proceed to the next step

for a finish cut.

20) Turn both Cut Depth Micro-meters

clockwise one small division to

move the cutting tool tips towards

the face of the rotor by 0.002 inch

(0.05 mm) Figure 14 illustrates that

0.002 inch is the distance between

two of the closest marks.

21) Turn the Feed Rate Switch on the

Drive Motor Control to 2 (slow

feed).

22) Press the top (INFEED) of the Feed

Direction Switch on the lathe. The

lathe cutting tools will automatically

feed inward making a finish cut on

the rotor. The cutting tools will

automatically stop at the setting

determined in Step 13 by setting the

Auto Infeed Stop button.

One rough cut and one finish cut are

normally sufficient for most applications.

If not, repeat rough and/or finish cuts as

required.

When a satisfactory surface finish has been obtained, press the

Safety Lock and move the AUTO/MAN Shift to MANUAL.

Back the cutting tool tips away from the rotor by turning the Cut

Depth Micrometers counter-clockwise.

Use the handwheel to back the cutting tools to a position beyond

the outer edge of the rotor.

Remove the Lathe and repeat the operation on the other side of

the vehicle.