8. fail, 9. simulate, 11. input contacts – Yokogawa EXAxt SC450 4-Wire Analyzer for Conductivity/Resistivity User Manual

Page 36: 7. contact output setup

28

IM 12D08N05-01E

5-8. Fail

A fail contact is energized when a fail situation

occurs. Fail situations are configured in secton

5-12. For SOFT Fails the contact and the dis-

play on LCD are pulsating. For HARD Fails the

contact and the display on LCD are energized

continuously. Only contact S4 is programmed

as a fail-safe contact. This means that contact

S4 will be de-energized when a fail situation

occurs.

Hard Fail Only

The contact reacts to Hard Fails Only

Hard + Soft fail

The contact reacts to Hard and Soft Fails

5-9. Simulate

The contact can be switched on/off or a

percentage of output can be simulated. On/Off

enables the user to manually switch a contact

on or off. The percentage is an analogue value

and represents the on time per period. The

Duty Cyde Period time (see figure 5-4) is used

as a period for percentage simulation. Note that

the (simulated) settings of the contacts become

visible in measuring mode and after HOLD has

ended c.q. has been overruled. A warning is

activated in case of a simulated output contact.

5-10. Water for Injection Monitoring

(USP 645 and EU 0169).

Setting up EXA SC450 for WFI monitoring

1. A function “USP limit exceeded” is defined

as an error code on sec. 5-12, Errors 2/3.

This can be set to off/warn/fail according

to your requirement. This function can

be modified by the function “USP safety

margin” in %. This is a percentage

of the WFI conductivity value at that

temperature that serves as safety margin.

This is independent of what is being

measured. The display shows this error

when the water quality exceeds the WFI

conductivity limits as set in stage 1.

2. We have introduced uncompensated

conductivity in the DISPLAY menu. In the LCD

display the user can read the temperature

and the raw conductivity to compare his water

quality with the WFI table.

3. We have added a USP function to the

contact allocation. The contact output S1

can be selected as USP alarm if the function

“USP limit exceeded” has been selected.

The contact closes when the USP limit is

reached.

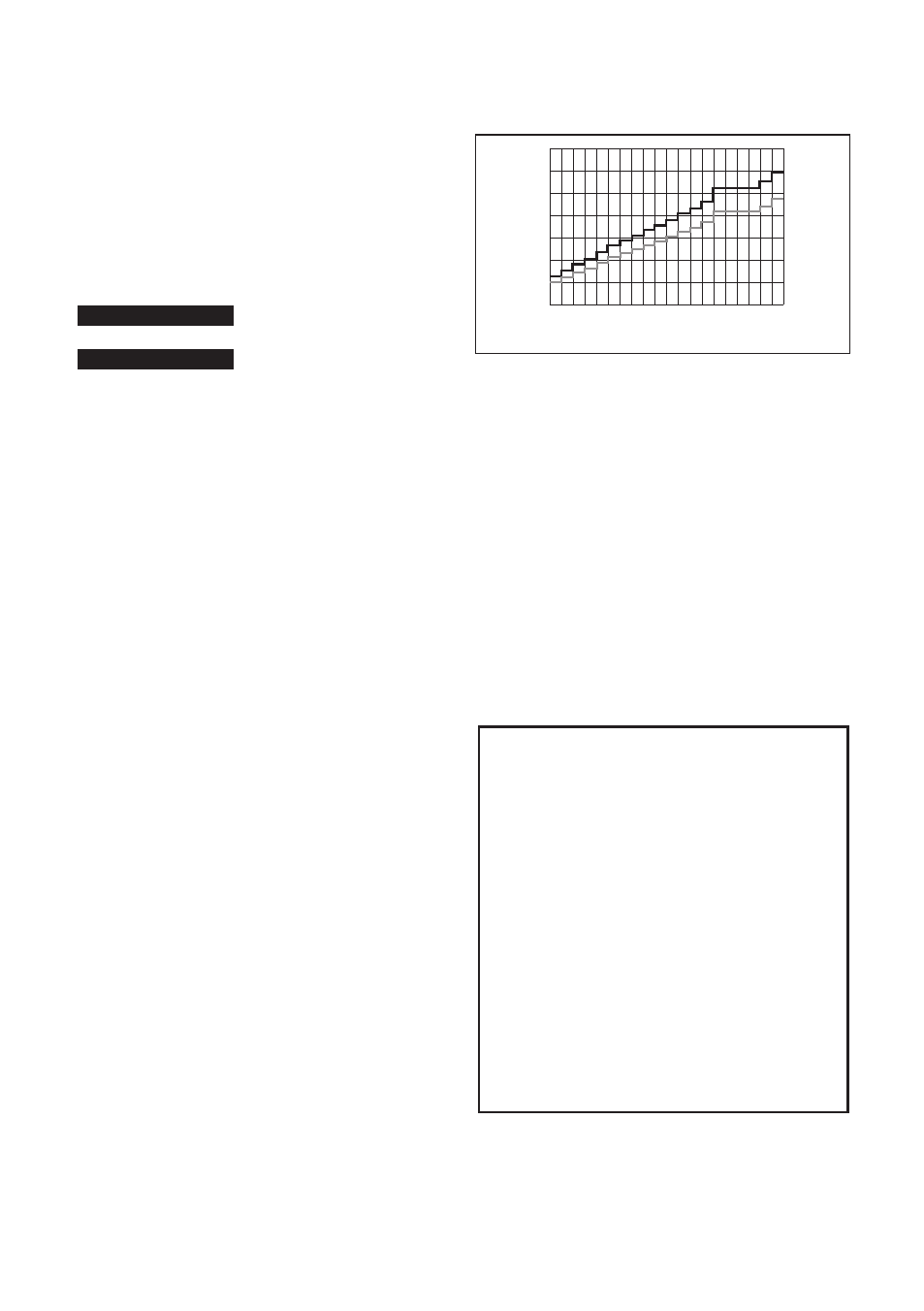

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

μS/cm

USP

Safety

Margin

25

50

75

100

˚C

Figure 5-6. USP Safety Margin

Limit of uncompensated conductivity as function

of temperature as defined for WFI. USP safety

margin set as 20 % will close the contact at 80 %

of the conductivity value at all temperatures.

For example, if the temperature is 64 ºC. and

the safety margin is adjusted for 20%, then the

contact closes at 0.8 x 2.2 μS/cm. = 1.76 μS/cm.

(2.2 μS/cm is the WFI limit at 64ºC). In resistivity

mode the contact will close at an uncompensated

resistivity of 1/1.76 μS/cm. = 0.568 Mohm.

Recommended Commissioning settings when

monitoring WFI in a > 80 ºC WFI installation.

Commissioning

Measurement Set up

Measure

Conductivity only

Temp Compensation

automatic

Conductivity 1

None

Error Configuration (Errors 2/3)

USP limit exceeded

Warn

Output Setup

S1

USP

USP safety margin 10 %

S2

Alarm

Parameter

Temperature

Setpoint

80 C

Direction

Low

Delay Time

0.2 s

Expiry Time

0 (disabled)

5-11. Input contacts

The terminal of the SC450G provides for an in-

put contact (see Figure 3-7). This input contact

can be used to switch the range of the outputs.

The range can be increased by 1 decade.

This is available for only mA1 output.