Troubleshooting, 1 overview, 2 operation principle – Yokogawa PK200 User Manual

Page 27: Troubleshooting -1, Overview -1, Operation principle -1

IM 21B03D01-01E

7-1

7. TROUBLESHOOTING

7.

TROUBLESHOOTING

7.1 Overview

If the PK200 converter does not operate normally,

check the condition carefully and solve any problem in

accordance with section 7.3 Troubleshooting Flow.

If problem appears difficult to correct, consult

YOKOGAWA service personnel.

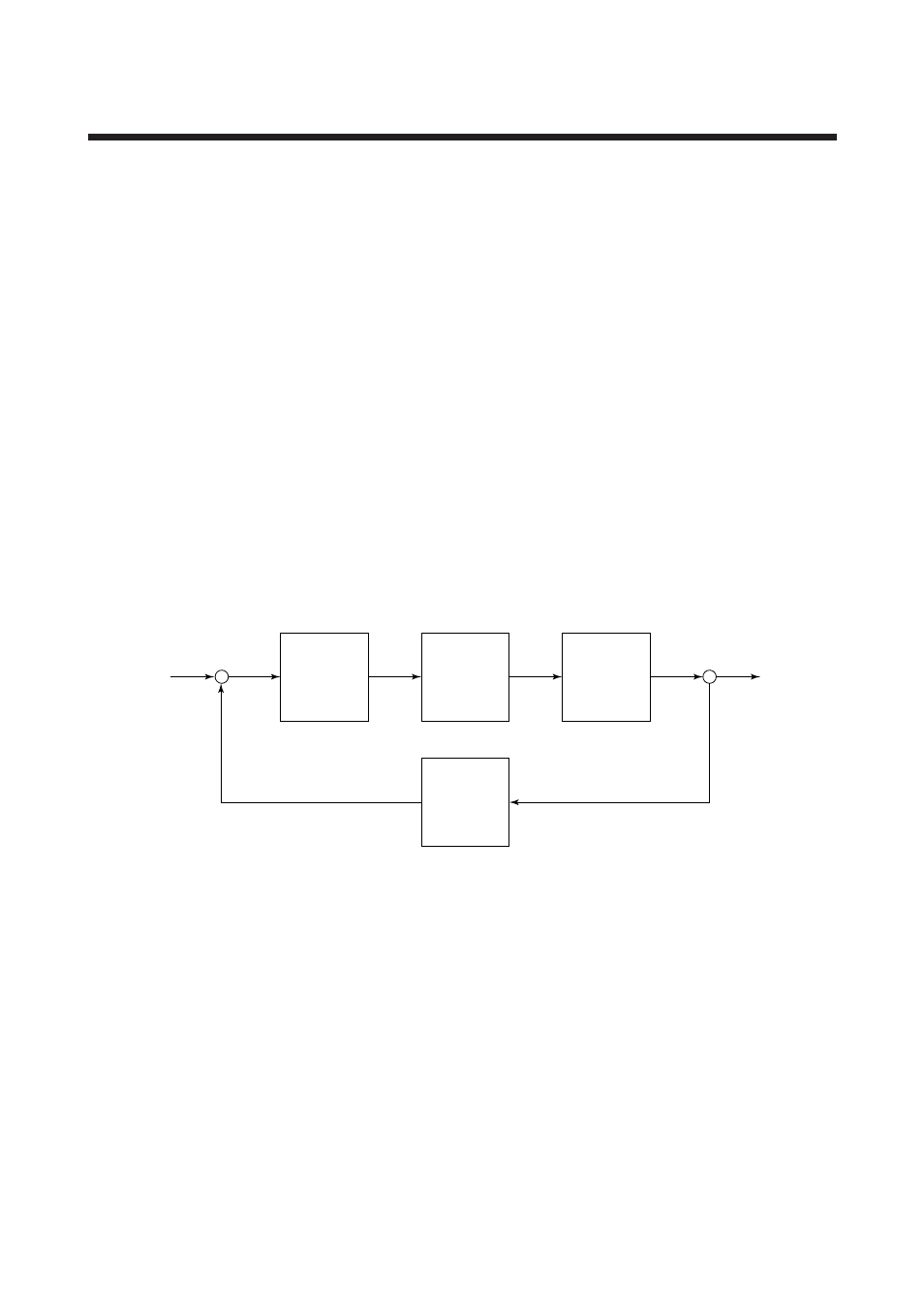

7.2 Operation Principle

The PK200 current-to-pneumatic converter accepts a 4

to 20mA or 10 to 50mA current signal from an

electronic controller as an operating signal. This signal

is input to a torque motor via an electric circuit,

generating a torque proportional to the current signal.

Torque

motor

Voltage

Voltage

–

+

4 to 20mA

input

20 to 100 kPa

Output

Nozzle

flapper

Pressure

sensor

Pilot relay

Position

Air

pressure

Air

pressure

F0701.EPS

Figure 7.1 PK200 Current-to-Pneumatic Converter Operation Principle Diagram

An increase in the input signal causes the flapper at the

end of the torque motor moving piece to move in the

nozzle closing direction. When the nozzle is closed,

back pressure increases, displacing the input diaphragm

inside the control relay. This causes the control relay

output air pressure to increase.

This output air pressure is output as PK200 converter

output pressure and is also input to a feedback pressure

sensor. The sensor then converts the pressure input into

an electric signal, which is fed back to the electric

circuit. The signal is then compared with the manipu-

lated output signal, the result of which activates

modification action until an output air pressure

balanced with the input signal is obtained.

In this way, an output air pressure proportional to the

input signal, which is a manipulated output signal, is

obtained.