2 wiring – Yokogawa PK200 User Manual

Page 16

IM 21B03D01-01E

4-2

4. WIRING AND PIPING

4.2.2 Wiring

(1) Install wiring away from noise sources such as a

large capacity transformer, motor, or power supply.

(2) Remove terminal box cover and wiring connection

dustproof plugs, then connect wiring.

Using an Allen wrench (width 3mm), unscrew the

locking setscrew and remove the flameproof cover.

Then, connect the wiring and when installing the

cover, do not neglect to fasten shrouding metal.

(3) It is recommended that clip-on terminals R1.25-5

or R2-5 be used for wiring termination (JIS C

2805).

(4) It is also recommended that wiring be installed in

conduits and ducts to provide protection against

water or external damage. For flameproof external

wiring, see 1.6 Installation of Flameproof Type”

and “INSTALLATION AND OPERATING

PRECAUTIONS FOR TIIS FLAMEPROOF

EQUIPMENT” at the end of this manual.

(5) When installing a flameproof gland packing

adapter (option code: /G11 and /G21) for cable

wiring, observe the following steps.

a. Release the shrouding metal and remove the

terminal box cover.

b. Measure the outside dia. of the cables to be used

in two directions in 0.1mm unit.

c. Obtain the average value of the measured values

in two directions and select a gland packing

whose inner dia. is nearest to the average value

from among those in Table 4.1.

d. Screw the flameproof packing adapter into the

terminal box until the O-ring touches the

terminal box wiring port (at least 6 full turns),

and tighten the lock nut.

e. Insert the cable through the union cover, the

union coupling, the clamp nut, the clamp ring,

the gland, one washer, the rubber packing, and

the packing box, in that order.

f. Insert the end of the cable into the terminal box.

g. Tighten the gland to grip the cable. When

tightening the union cover, tighten approximately

one turn past the point where the cable will no

longer move up and down.

Proper tightening is important. If it is too tight, a

circuit break in the cable may occur; if not tight

enough, the flameproof effectiveness will be

compromised.

CAUTION

Tighten the gland approximately one turn after

the point where you can no longer shift the cable

up and down by hand.

Take great care in this step, since proper

tightening is very important.

h. Fasten the cable with tightening the clamp nut.

i. Tighten the lock nut on the union cover.

j. Connect the cable wires to each terminal.

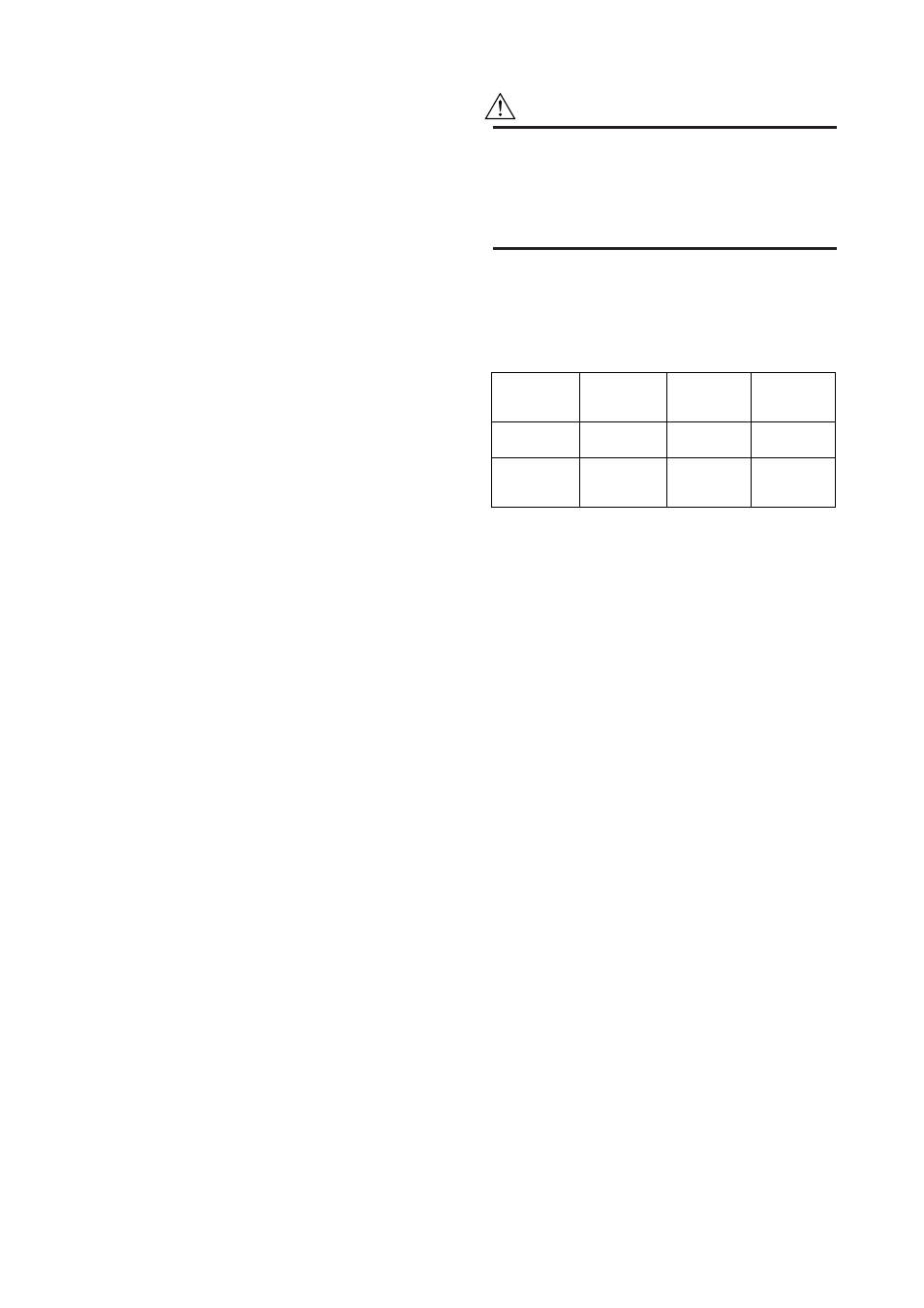

Table 4.2 Type of Packing and Applicable Cable O.D.

G1 / 2

8-10

16

8-10

G9601AM

10.1-12

16 10-12

G3 / 4

10-12

22 10-12

G9601AN

12.1-14

22 12-14

14.1-16

22 14-16

Wiring port

thread diameter

Appropriate

cable outer

diameter (mm)

Identifying

mark

Part Number

T0402.EPS

(6) Install a sealing fitting (option) to be used for

metal conduit lines, in the following order.

a. Assemble a sealing fitting into the instrument.

Apply sealing compound to the nipple provided

and screw in the nipple by seven to eight turns,

then fix it with a lock nut.

b. Install wiring using insulated wires and provide a

compound filling chamber of inorganic material

by using sealing dams. (See Figure 4.5.)

c. Fill sealing compound from the compound filling

port until the fitting is filled with the compound.

Example of sealing compound

Shimada Electric (1kg can)

For FG5: Approx. 100g/P. filling

For FG6: Approx. 115g/P. filling

d. After the compound has been sufficiently

softened, screw the plug into the filling port.

e. Connect a metal conduit for piping (JIS C 8305)

or explosion-proof flexible fitting to the sealing

fitting by engaging five or more threads.

f. For the details of sealing, see 3.3.2.3 in the

“Recommended Practice of Explosion-Protected

Electrical Installations in General Industries”

published by the Industrial Safety Institute,

Ministry of Labor (Japan).