Yokogawa PK200 User Manual

Page 25

IM 21B03D01-01E

6-3

6. MAINTENANCE

(7) Pull out the amplifier directly, taking care not to

bend the zero adjustment control.

(8) Remove the silicon tube left in the case.

Mounting the Amplifier

(1) Insert the accessory silicon tube into the body cap

firmly.

F0608.EPS

Tube pin on case

Figure 6.8 Silicon Tube Case Cap

CAUTION

Be sure to use the accessory silicon tube that

comes with the amplifier for replacement. Note

that the tube size varies depending on the

amplifier to be used. Be sure to use the proper

tube to prevent air leakage and precision dete-

rioration.

(2) Adjust the angle so that the volume knob of zero

adjustment forms a right angle with the amplifier.

F0609.EPS

Volume Knob of zero point adjustment

Figure 6.9 Zero Adjustment Control

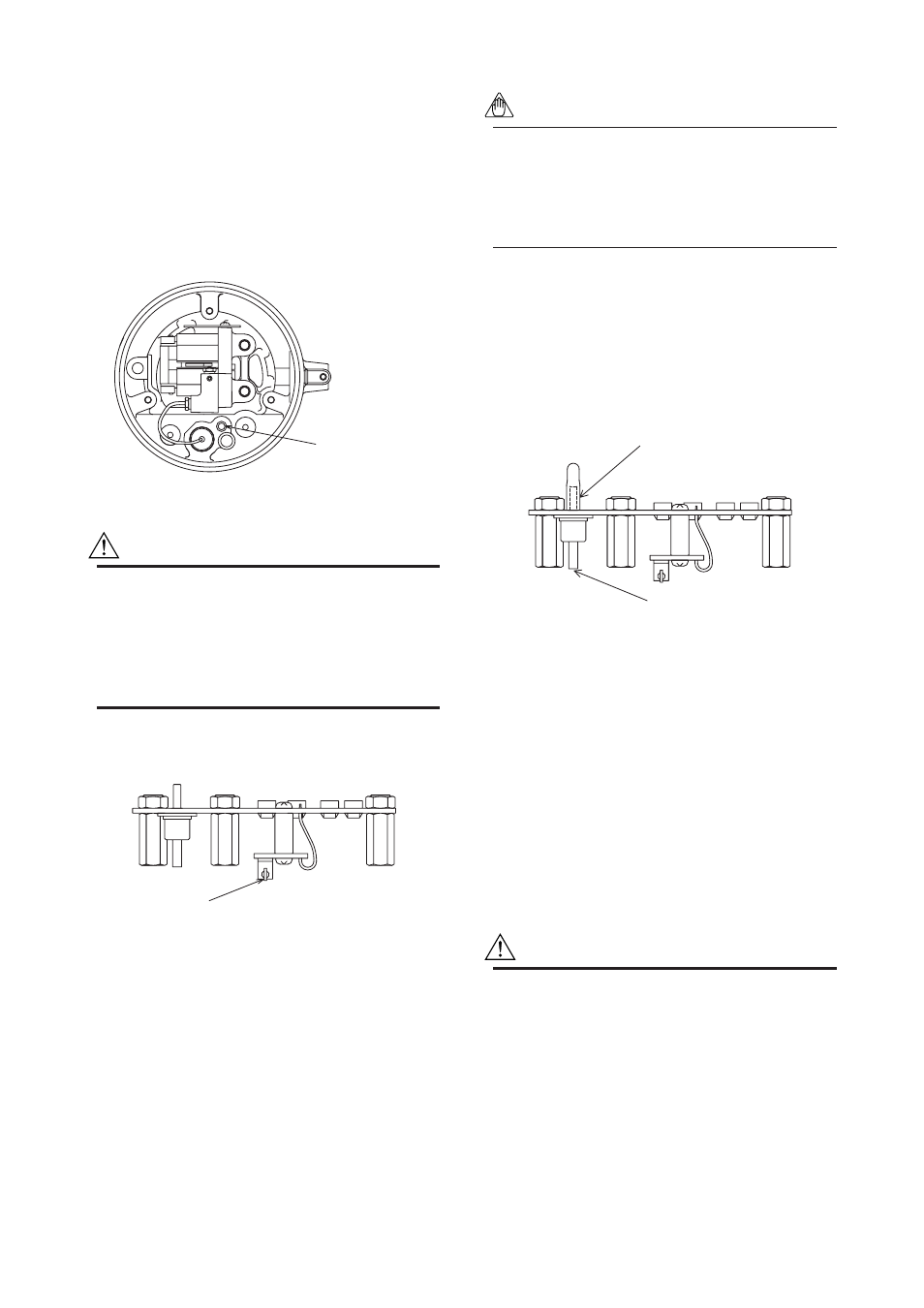

(3) Pass the silicon tube through an amplifier hole and

mount the amplifier directly so that the sleeve of

the pressure sensor leads into the hole of the case.

NOTE

1.Do not apply undue pressure to the pressure

sensor.

2.Do not bend the zero adjustment volume knob

to prevent it from contacting the zero adjust-

ment set screw.

(4) Fasten the four set screws for fixing the amplifier

(see Figure 6.7).

(5) Connect the four wires in the order of yellow

(ACT+), white (ACT-), red (IN+) and black (IN-).

(6) Insert the silicon tube into the amplifier pressure

sensor firmly.

F0610.EPS

Silicon tube

Pressure sensor

Figure 6.10 Pressure Sensor and Silicon Tube

(7) In a model allowing 4-20/10-50mA selection, refer

to 5.5 to set the socket switch as necessary.

(8) Mount the amplifier cover.

Inspection after Amplifier Replacement

After replacing the amplifier, perform the insulation

resistance test and withstand voltage test. Be sure to

perform them according to the following procedure,

referring to the corresponding tester instruction

manuals.

CAUTION

(1) Overvoltage of the test voltage that is so

small that it does not cause an dielectric

breakdown may in fact deteriorate insulation

and lower the safety performance; to prevent

this it is recommended that the amount of

testing be kept to a minimum.

(2) The voltage for the insulation resistance test

must be 500V DC or lower, and the voltage

for the withstand voltage test must be 500V

AC or lower. Failure to heed these guidelines

may cause faulty operation.