Operation, 1 auto/manual (a/m) transfer mechanism, 2 zero point adjustment – Yokogawa PK200 User Manual

Page 19: Operation -1, Auto/manual (a/m) transfer mechanism -1, Zero point adjustment -1

IM 21B03D01-01E

5-1

5. OPERATION

5.

OPERATION

5.1 Auto/Manual (A/M) Transfer

Mechanism

Please refer to following instruction for the model with

A/M selector switch (optional code: /AM).

For the model without A/M selector switch, please go

to section 5.2.

Use of A/M transfer mechanism requires that a supply

pressure adjusting reducing valve be installed.

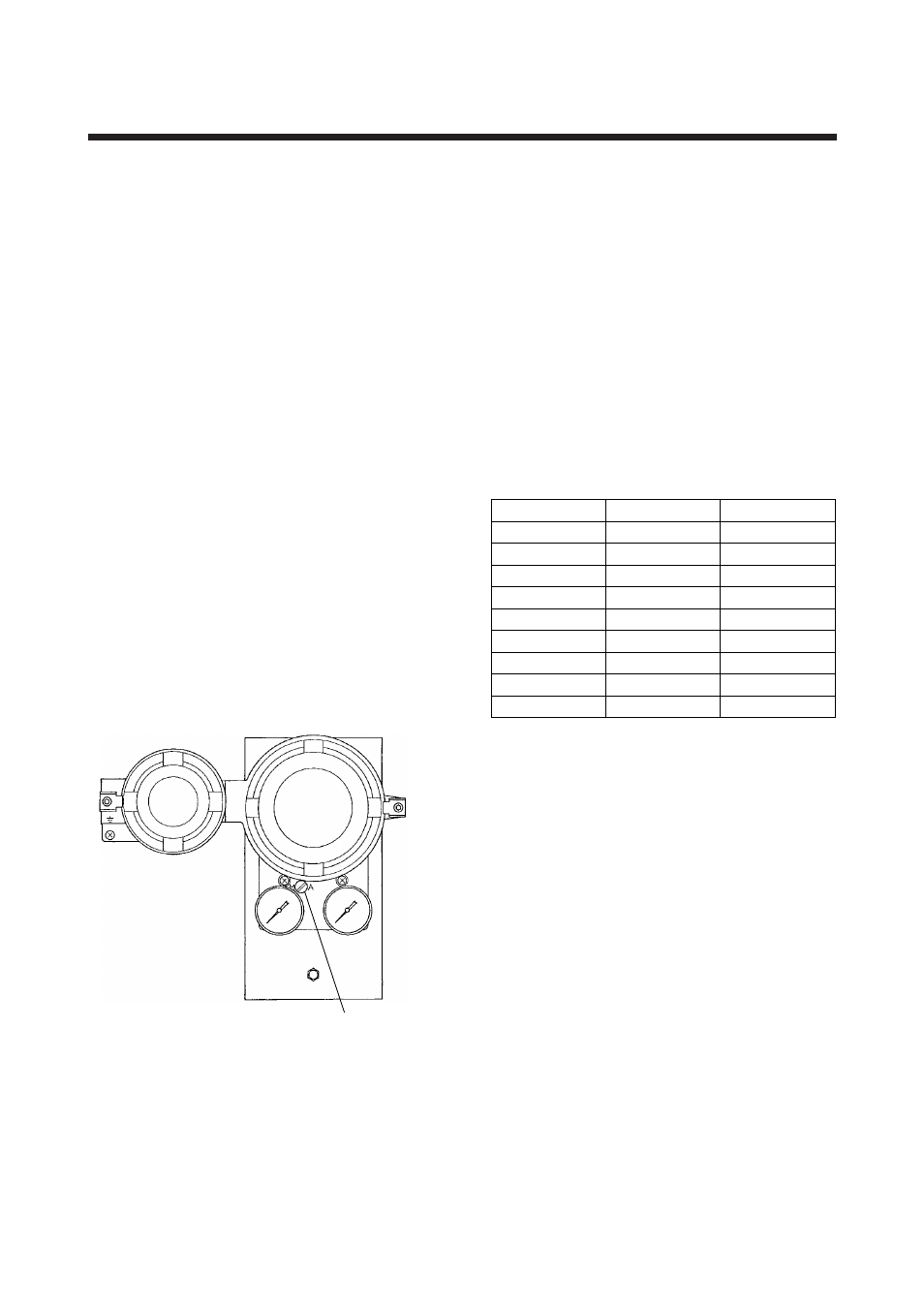

(1) Set the A/M selector switch provided at the front

(on the supply air pressure gauge side) of the

converter to “M.” (Turn the switch clockwise.)

(2) This allows supply air pressure to be output, which

is supplied to the control valve.

(3) Output air pressure can be regulated using the

pressure regulator. Because the output pressure is

not same as supply pressure, it is necessary to

adjust it watching an output pressure gauge

attached to this instrument. Pressure gauge mini-

mum unit is 10kPa (standard output type) or 20kPa

(doubled output type).

A/M selector switch

F0501.EPS

Figure 5.1 Auto/Manual Transfer Mechanism

5.2 Zero Point Adjustment

(1) For the model with A/M selector switch, please set

the A/M selector switch to A (Auto). (Turn the

switch counterclockwise.)

(2) Apply supply air pressure to the current-to-

pneumatic converter.

For supply air pressure, see the data plate or Table

5.1 “Supply Air Pressure.”

Standard output applies for model suffix output

signal code “1, 3, 5, 7” and multiplied pressure

output for model suffix output signal code “2, 4, 6,

8, 9.”

Table 5.1 Recommended Supply Air Pressure

Output Signal Code

Output Signal

Supply Air Pressure

1

20 to 100kPa

130 to 150kPa

2

40 to 200kPa

230 to 260kPa

3

0.2 to 1.0kgf/cm

2

1.3 to 1.5kgf/cm

2

4

0.4 to 2.0kgf/cm

2

2.3 to 2.6kgf/cm

2

5

0.2 to 1.0bar

1.3 to 1.5bar

6

0.4 to 2.0bar

2.3 to 2.6bar

7

3 to 15psi

19 to 22psi

8

6 to 30psi

34 to 37psi

9

3 to 27psi

34 to 36psi

T0501.EPS

(3) Then input an input signal.

Input a 0% electric signal.

Apply 4mA for 4 to 20mA input or 10mA for 10

to 50mA input.

(4) Make zero point adjustment so that the output air

pressure reaches the specified pressure.

For output air pressure, see the data plate or Table

5.2 “Output Signals.”

To increase output air pressure, turn the zero

adjustment clockwise. To decrease the pressure,

turn the zero adjustment counterclockwise. (See

Figure 5.2.)

For the model with reverse action (/RA), please

turn zero adjustment counterclockwise to increase

output air pressure. To decrease output air pres-

sure, please turn zero adjustment clockwise.