4 disassembly and assembly, Disassembly and assembly -2, Caution – Yokogawa Wireless Temperature Transmitter YTA510 User Manual

Page 53: Important

<8. Maintenance>

8-2

IM 01C50E01-01EN

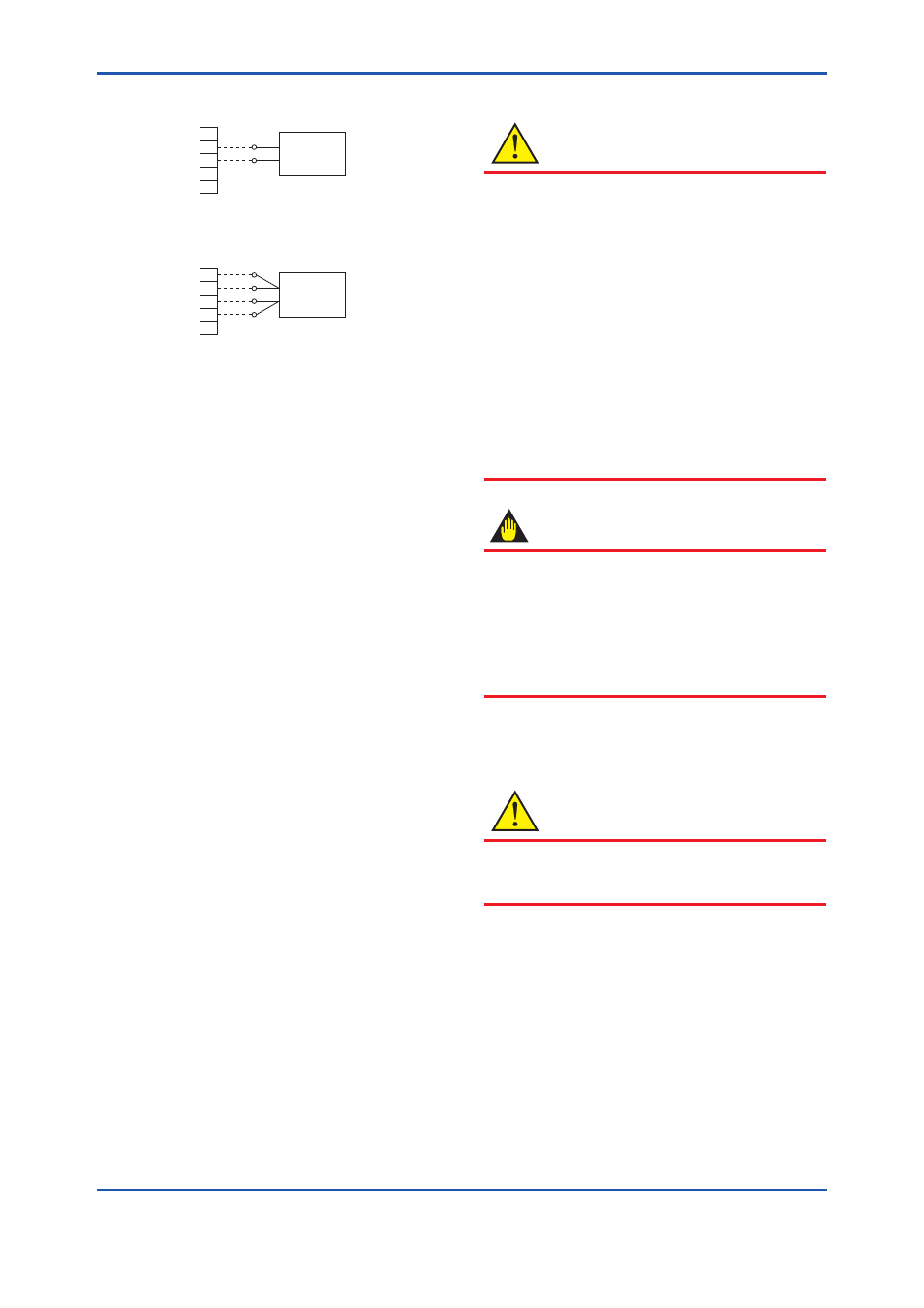

Example of wiring for thermocouple or DC voltage input

F0801.ai

DC voltage generator

1

2

3

4

5

Example of wiring for RTD 4-wire type

Variable resistor

1

2

3

4

5

(B)

(B)

(A)

(−)

(A)

YTA sensor

input terminal

YTA sensor

input terminal

(+)

Figure 8.1

Example of wiring for calibration

equipment

4) Calibration Procedure

a) For DC voltage input

With a voltage generator, deliver input

signals corresponding to 0, 25, 75, or

100% of the input span to the temperature

transmitter.

b) For thermocouple input

Since this instrument is equipped with a cold

junction compensating function, use a cold

junction compensating function in universal

calibrator in order to compensate for this

function upon calibration. According to the

reference millivolt table for thermocouple,

obtain millivolt corresponding to 0, 25, 50,

75, or 100% of the span, and use that power

as the input value, then deliver it from the

universal calibrator to the temperature

transmitter. Check the output value for that

input value.

c) For resistance thermometer (RTD) input

Using a thermometer resistor as input,

calibration of the temperature transmitter

is carried out via a 4-core wire connection.

As defined in the reference resistor value

table of the resistance thermometer (RTD),

obtain resistance values corresponding to

0, 25, 50, 75 or 100% of the span, and use

the obtained resistance as the input value,

then deliver it to the temperature transmitter

by means of a variable resistor. Check the

output value for that input value.

Apply a specified input signal following steps

a) to c) above. If the output signal is outside

the accuracy range, perform output adjustment

using the device configuration tool. For

details on how to perform adjustment, refer to

subsection 7.3.13 Input calibration.

8.4 Disassembly and Assembly

CAUTION

Precautions for the intrinsic safety explosion

prevention type instrument

Intrinsic safe type transmitters must be, as

a rule, removed to a non-hazardous area

for maintenance and be disassembled and

reassembled to the original state. Check the

insulation, and execute Insulation Test, when it

is disassembled and reassembled to the original

state.

Refer to section 2.7 “Insulation Resistance and

Dielectric Strength Test” for details of Resistance

Test.

Refer to "Precautions for the intrinsic safety

explosion prevention type instrument" in the end

of this manual of details.

IMPORTANT

• Perform the provisioning when replacing the

RF assembly. Refer to 6.4 Connecting to the

Field Wireless Network for details.

• Replace the batteries and perform the

parameter settings when replacing the CPU

assembly. Refer to 8.4.5 Replacing the

Batteries.

This section describes procedures for disassembly

and reassembly for maintenance and component

replacement.

CAUTION

Always remove the battery pack and shut off

before disassembly. Use proper tools for all

operations.