Mvdc process input, Mvdc process input procedure – Watlow Calibrating Watlow Series 988 Family Process Controls User Manual

Page 13

WATLOW Series 988 Calibration Manual

13

mVDC Process Input

mVDC Process Input Procedure

0 to 50mVDC and 0 to 100mVDC units

Equipment Required

•

Precision millivolt source, 0-100mV minimum range with 0.001mV resolution

Setup and Calibration

1. Connect the AC voltage L1, L2 and ground to the proper terminals on the

Series 988. See Chapter 2 in the user's manual.

2. For Input #1 calibration: Connect the millivolt source to terminal #8 (-) and

terminal #10 (+) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

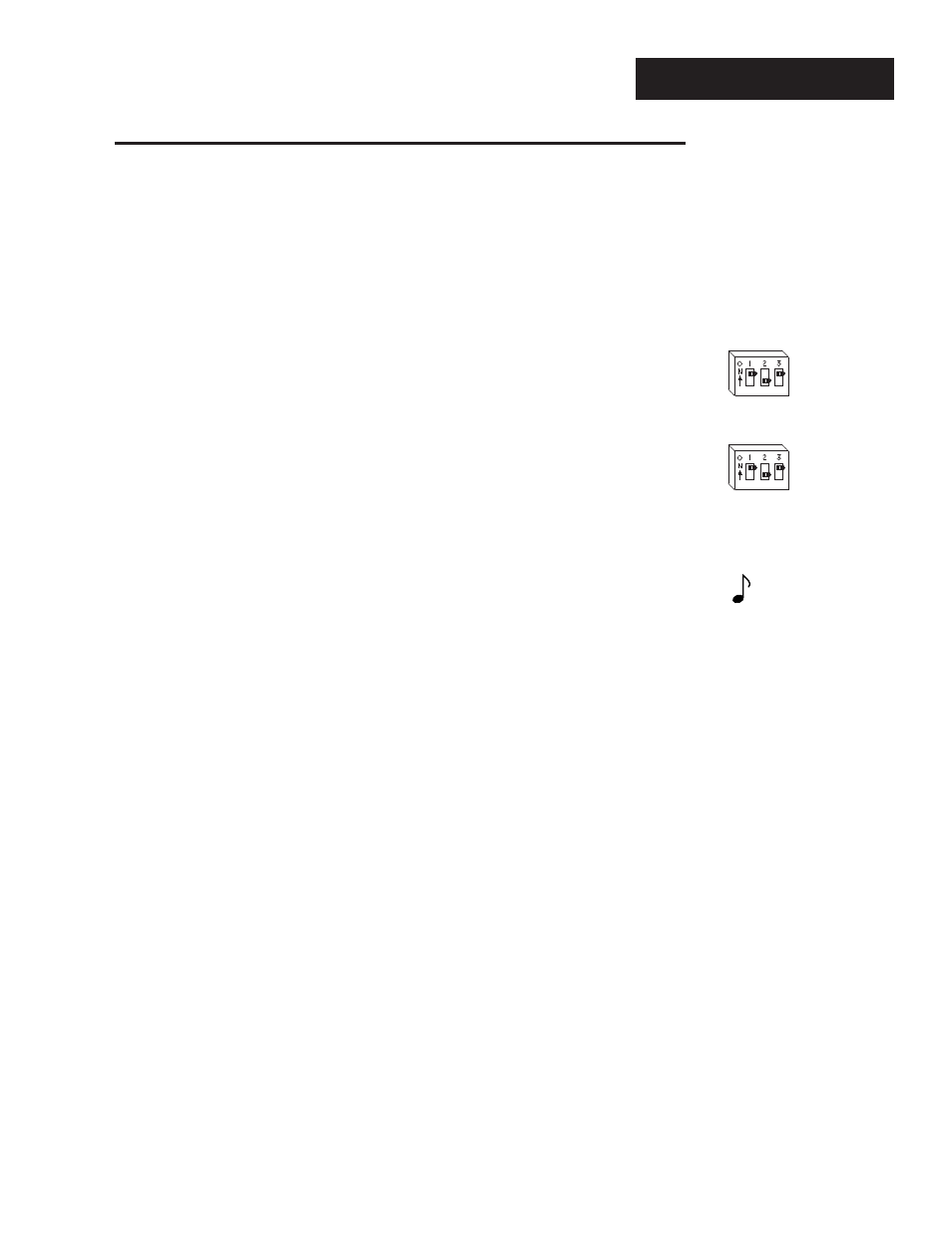

Remove the control from the case and set the Input 1 DIP switches to:

1 ON

2 OFF

3 ON

For Input #2 calibration: Connect the millivolt source to terminal #18 (-) and

terminal #20 (+) on the 988 terminal strip. Use 20 to 24 gauge copper wire.

Remove the control from the case and set the Input 2 DIP switches to: 1

1

ON

2 OFF

3 ON

3. Apply power to the unit and let it warm up for 15 minutes. After warm up put

the unit in the CAL menu. See Page 6.

When performing calibration procedures, always do the Input 1 prompts

(beginning with an “A”) first, then continue on to the Input 2 prompts

(beginning with a “B”). See the Calibration menu on Page 6.

4. At the A 0U or B 0U prompt, enter 0.000mV from the millivolt source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key.

5. At the A100 or B100 prompt, enter 100.00mV from the voltage source to the

Series 988. Allow at least 10 seconds to stabilize. Press the Up key to change

the upper display to YES. Press the Mode key. To conclude the millivolt

process calibration, press the Display key.

NOTE:

Any prompt begin-

ning with an “A”

applies to Input 1.

Those beginning

with a “B” apply to

Input 2.