Hydraulic installation instructions, Operating instructions, Bill of materials – SaltDogg 92420, -30 Series Under Tailgate Spreader User Manual

Page 5: Hydraulic pump diagram

Quality since 1946

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

Hydraulic

Installation Instructions

A. During assembly take precautions to keep all

hydraulic components as clean as possible.

B. Allow enough hose length to prevent kinking

and stretching of the hoses and to permit raising

the dump body. Support long hoses with wire ties

or clamps.

C. Protect hoses from wear caused by sliding and/

or vibration.

D. For proper rotation of auger and spinner motors,

hoses may be reversed.

Note: Use of a pipe joint sealant compatible with

hydraulic oil is recommended for all screw fittings.

E. Use swivel type hose ends to connect hoses to

flow valve. Damage to valve body may occur if the

fittings in flow valve are over tightened

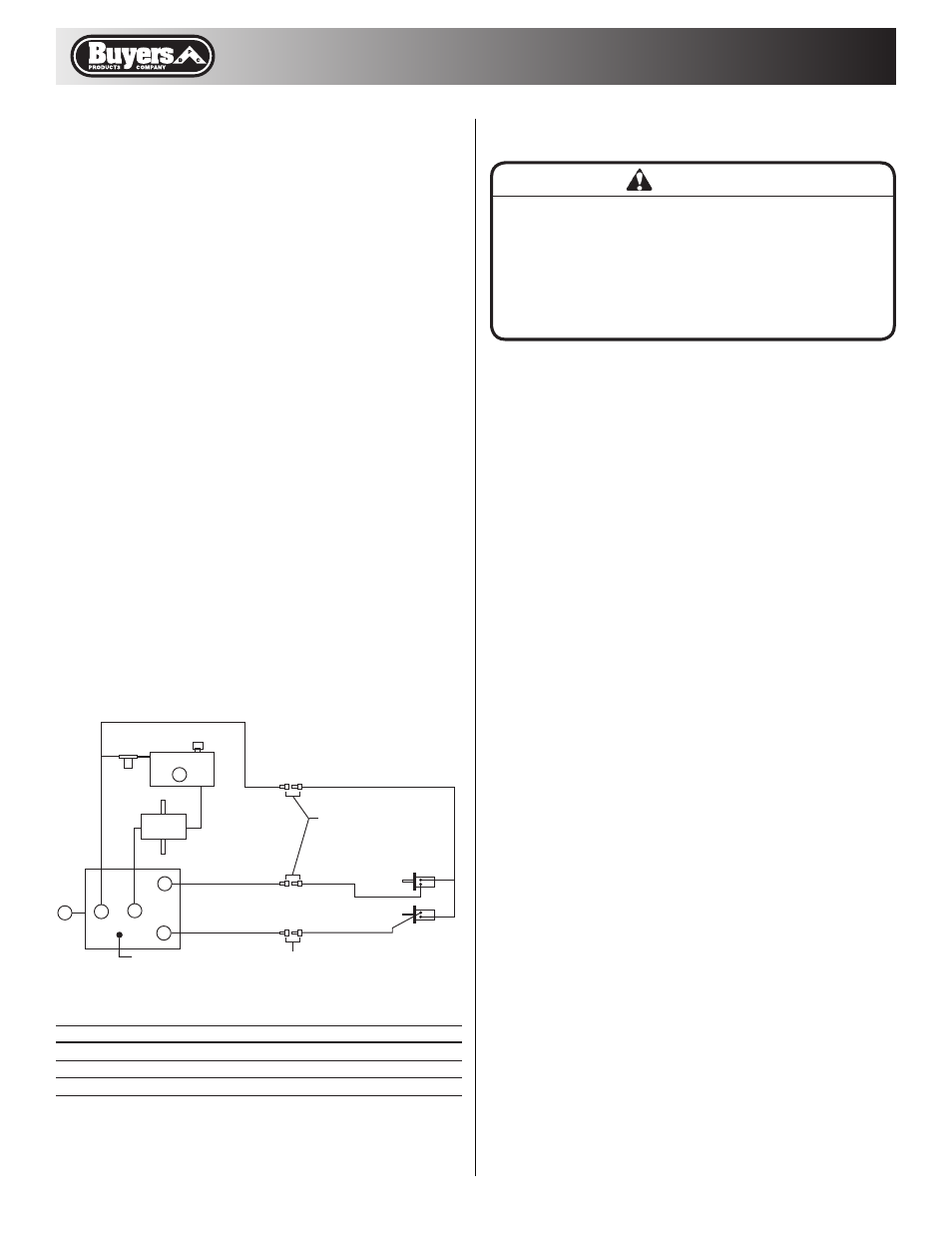

Valve

1/2" Quick Disconnects

3/4" (1)

Wire Hose

3/4" (1) Wire Hose

1/2" (1) Wire Hose

1/2" (1) Wire Hose

1/2" (1) Wire Hose

Auger Motor

CW Rotation

Spinner Motor

CCW Rotation

3/4" Quick

Disconnects

3/4" (2) Wire Hose

1-1/4" Spiral

SuctionHose

3/4" (2) Wire Hose

1/2" (1) Wire Hose

Tank

Pump

3

1

T

A

P

S

Bill of Materials

1

HV715

1

Dual Flow Regulator Valve

2

HVC1

1

Dual Flow Regulator Console

3

SMR15

1

15 Gallon Reservoir

item

part no.

qty.

description

Hydraulic Pump Diagram

Operating Instructions

1. Pre-start up.

A. Use high grade non foaming hydraulic oil to fill

reservoir about 3/4 full.

B. Position valve on/off lever to off.

C. Move auger and spinner knobs on the valve to

the open position.

D. Engage PTO and circulate hydraulic oil for sev-

eral minutes to warm up.

E. Move valve on/off lever to on.

F. Inspect hydraulic system for leaks.

G. Check auger and spinner to see if they are work-

ing properly.

H. Refill reservoir to 3/4 full.

I. Hydraulic system should now be ready for use.

2. Initial use of spreader

A. Shut off spinner and auger knobs and position

the on/off lever to on. Engage the PTO and allow

the hydraulic system to warm up.

B. Open the cover plate and secure vertically with

locking brackets.

C. Open dump body tailgate as wide as possible

from bottom without bearing against cover plate.

Set stop chains.

CAUTION

A. Be sure everyone is standing clear.

B. Be alert for anything that may require shutting

down the system.

C. Before working in or around spreader equip-

ment, be sure all hydraulic controls are moved to

off position.