Spreader maintenance – SaltDogg 1400701SS Self-Contained Stainless Steel Hopper Spreaders User Manual

Page 5

55

TM

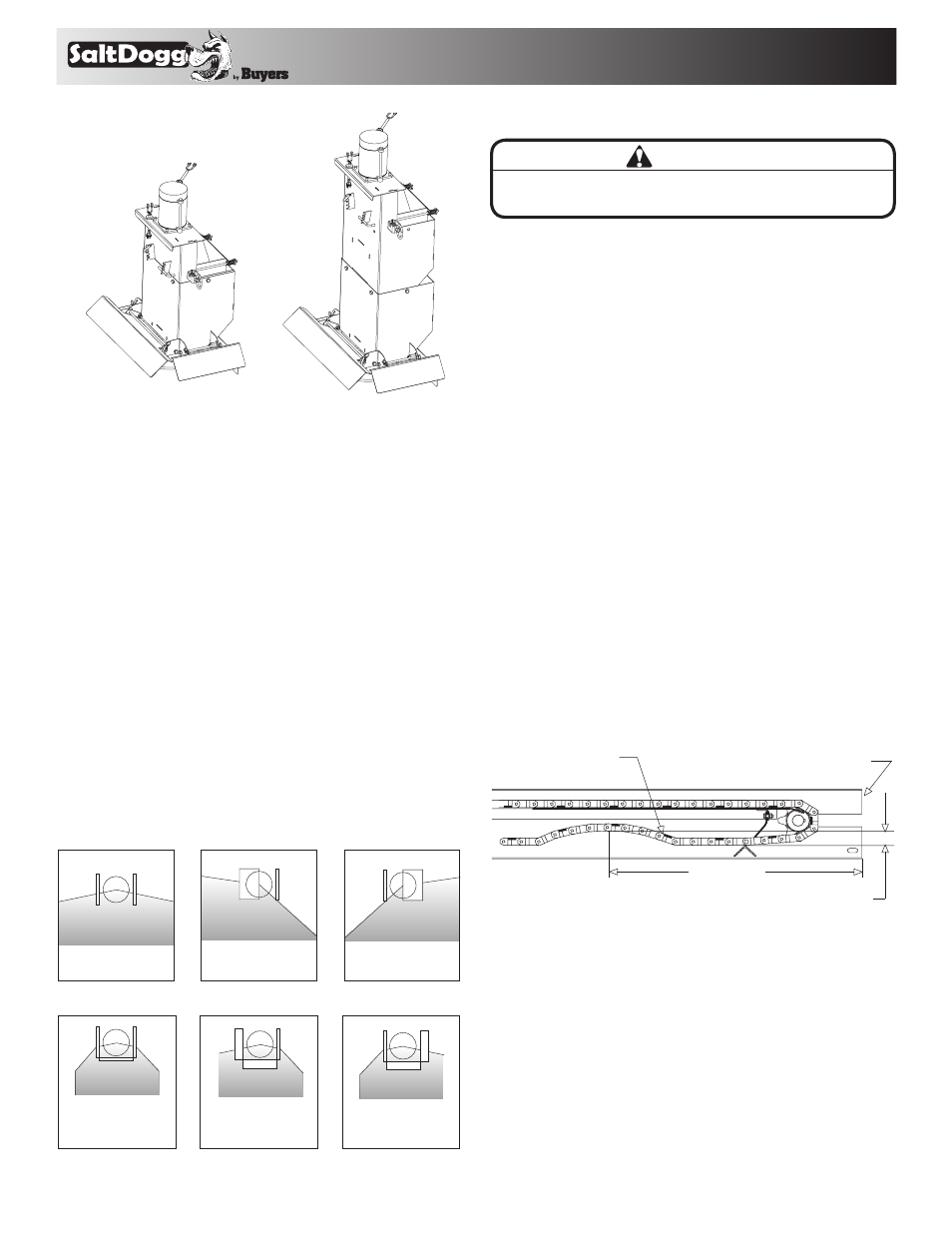

3. Spinner/Chute Assembly Operation

Attach chute to hopper assembly by inserting tabs into slots

in chute motor plate. Then secure chute by engaging spring

latches in respective holes. Chute heights can be adjusted

by attaching lower chute weldment to the upper one using

upper or lower set of holes. Two sets of holes are located

on the bottom of upper chute weldment and under internal

baffles selectors.

Adjustable shaft can be connected in two positions: upper

and lower. Two sets of holes are located in upper and lower

portions of coupler. Shaft to be secured by 5/16 cross bolt

and nut.

A. The spread pattern and the amount of material dispensed

is dependant on the following factors:

1. Gear Motor RPM

2. Feed gate position

3. Baffle settings

4. Spinner Motor RPM

Below are illustrations that show the baffles effect on the

spread pattern as viewed from the top of the spinner disk.

Both internal

baffles out

Left baffle in,

Right baffle out

Right baffle in,

Left baffle out

All baffles adjusted

down for a confined

spread pattern

Right baffle deflects

material down;

heavy on right side

Left baffle deflects

material down;

heavy on left side

Internal Baffle Adjustment

External Baffle Adjustment

CAUTION

Always follow the following precautions so as not to

cause damage to the spreader.

4. Precautions

A. If the feed chain does not move because of dense material

or a material jam, remove all material from the hopper and

free the chain.

B. If the material in the hopper freezes, move the spreader

into a warm area to thaw.

C. To prevent the feed chain from freezing, do not store

material in the spreader.

D. The gearbox is designed to only accept torque from the

electrical motor. Therefore, DO NOT ATTEMPT TO FREE

THE FEED CHAIN BY USING A PIPE OR SIMILAR TOOL

TO MOVE OR DISLODGE THE CHAIN. If the feed chain

is moved, the gears within the gearbox will strip. This

action will void all warranties.

Spreader Maintenance

1. Use dielectric grease on all electrical connections before

an electrical connection is made or after a connector is

disconnected.

2. Grease the following:

• Idler shaft bearings (2)

• Bearing (1)

• Spinner shaft bearing (1)

3. Check the Feed Chain tension periodically.

To check the tension, measure in 21"-25" from the rear

edge of the gear box mount. Push up on the chain with

your hand. The conveyor chain should lift up 2"-3" off the

conveyor chain guide or cross angles.

4. Empty the spreader of all ice control material when not in

use to prevent a frozen feed chain.

5. Wash out the spreader when it is not in use. At the end of

the season wash out the spreader to remove all ice control

materials. Thoroughly dry all metal surfaces. Paint and oil all

bare metal surfaces and chains to protect from rust. Properly

store the spreader for the next season.

Feed

Chain

Rear of Sill

Extension

2" - 3"

21" - 25"