SaltDogg SHPE2000 Series Electric Drive Poly Hopper Spreader v.3 User Manual

Page 3

3

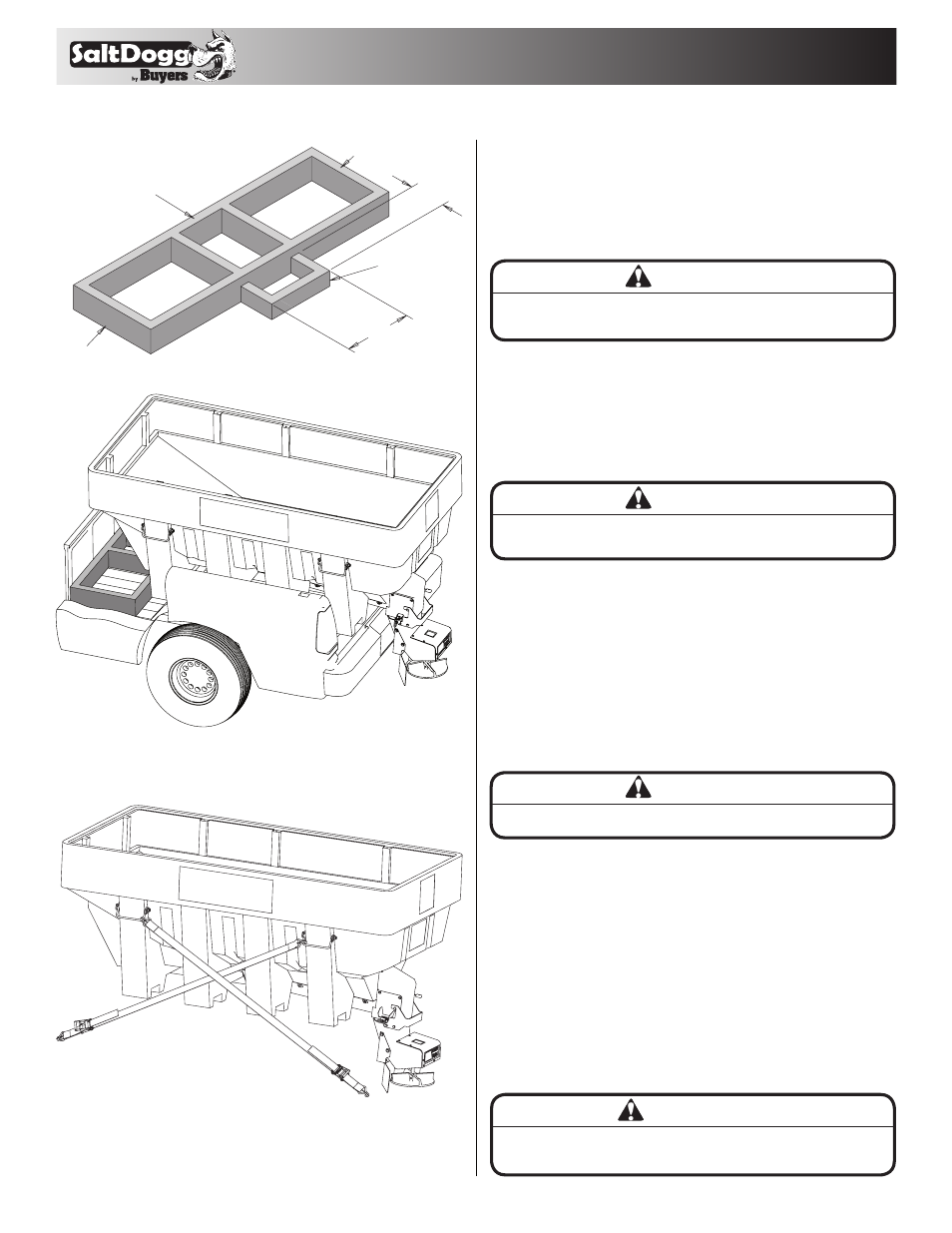

H. Secure spreader using four ratchet straps as shown in

Fig. 6. Tighten straps evenly to secure spreader in the

middle of the truck box.

15"

8"

2" x 4"

2" x 6"

FIT TO BOX

FIT TO BOX

Fig. 4

Fig. 5

Verify with the vehicle’s manufacturer that the factory

installed anchor points are designed for tie-down such

load. Inspect straps and hardware after each time spreader

is loaded. Tighten straps and hardware if necessary.

Fig. 6

2. Install Control Box & Vehicle Wiring Harness (Fig. 7).

NOTE: THIS IS A WIRE GROUND ELECTRICAL SYSTEM!

NO CONNECTIONS TO TRUCK'S FRAME OR BODY

ALLOWED! ALWAYS DISCONNECT BATTERY BEFORE

ATTEMPTING TO INSTALL ELECTRICAL COMPONENTS

ON YOUR VEHICLE.

To insure good performance of your spreader, check the

condition of truck’s electrical system. Using digital voltmeter,

check alternator and battery voltage. The voltage reading

should fall between 13.6 & 15.3 volts with engine running,

head lights and heater fan turned on. If voltage reading falls

out of this range, check & adjust your electric system.

A. Lay out a wiring path for the Vehicle Wiring Harness.

Connect the Wire Harness smaller terminal to the Chute’s

harness, large terminal to the Hopper’s harness. Drill all

necessary holes or use existing ones to pass the round

connector into the trucks cab. Secure harness to truck’s

frame.

B. Mount the Controller in a convenient location in the truck

cab. Do not mount controller directly in front of the heat

vents. Allow ample air space around controller. Protect

controller from water, dirt and dust.

WARNING

Do not drill holes into fuel tanks, fuel lines, through electrical

wiring, etc that may be damaged by drilling.

WARNING

Use extreme caution when working around an operating

vehicle engine.

C. Apply dielectric grease or similar compound to connectors

before assembly. Connect the round connector on the wire

harness to the round connector on the controller.

D. Lay out path for the power cable in the truck’s engine

compartment. Drill hole in the firewall or use an existing

one to pass the wire harness. Passing the power cable from

inside of the cab to the battery is recommended to protect

the large high amperage connector. Do not route the power

cable close to exhaust system!

E. Connect power cable connector to controller.

F. Connect the power cable ring terminals to the truck

battery, white-positive, and black-negative.

ATTENTION

Do not connect black (negative) wire to any part of vehicles

frame. Connect this terminal to battery’s negative terminal.

CAUTION

DO NOT MOUNT CONTROLLER IN WAY OF AIR BAG DEPLOYMENT